Production method for improving yield-strength ratio and stretch-flange-formability of cold-rolled DP980 steel

A production method and yield-strength ratio technology are applied in the production field of improving the yield-strength ratio and hole-enlarging performance of cold-rolled DP980 steel, and can solve the problems of inability to satisfy hole-enlarging, flanging, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

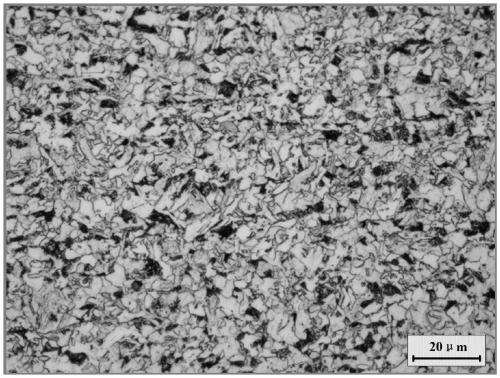

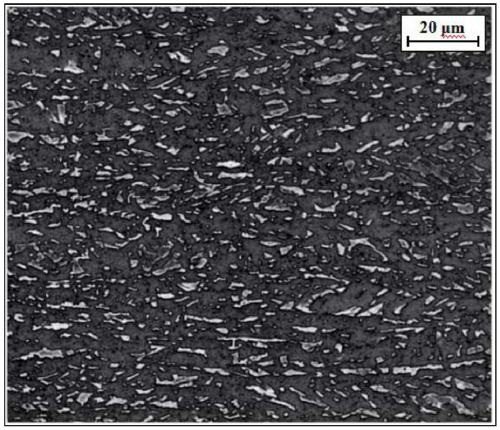

Examples

Embodiment 1~3

[0019] Embodiments 1-3: A production method for improving the yield ratio and hole expansion performance of cold-rolled DP980 steel according to the present invention is as follows.

[0020] The chemical composition of steel slabs in Examples 1-3 of the present invention includes C: 0.080-0.130%, Si: 0.28-0.50%, Mn: 2.00-2.50%, Alt: 0.040-0.070%, Cr: 0.40-0.70% by weight percentage , Mo: 0.20~0.30%, Nb: 0.020~0.050%, and limit N≤0.005%, P≤0.008%, S≤0.005%, O≤0.003%, and the balance is Fe and other unavoidable impurities. The chemical composition of the tapping molten steel of the billet in specific embodiments 1-3 is shown in Table 1, and the thickness of the billet is 230mm.

[0021] The actual smelting composition (mass percentage, %) of the embodiment of table 1

[0022]

[0023] In Examples 1 to 3 of the present invention, the thickness of the hot-rolled base material is 2.00mm

[0024] The technical proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

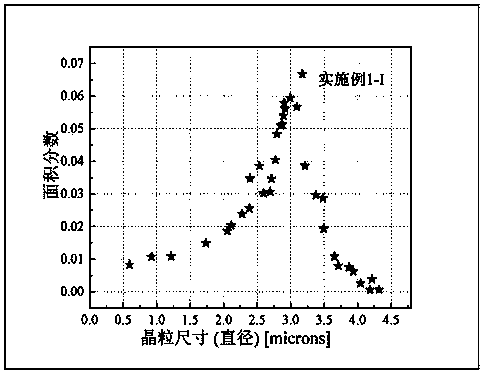

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com