Frame-type concrete silo

A concrete and frame-type technology, applied in climate change adaptation, building types, buildings, etc., can solve the problems of self-heavy, overall cost increase, construction difficulty, etc., achieve good lateral pressure and vertical pressure, and improve thermal insulation effect. , The effect of solving the lifting problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

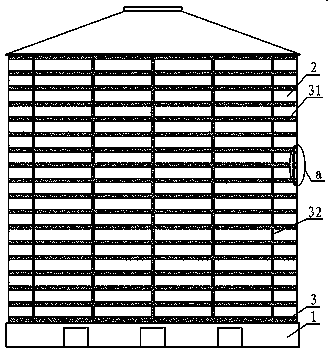

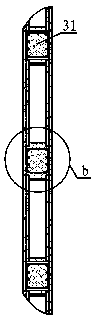

[0051] A frame-type concrete cylinder silo is composed of: a concrete body foundation 1, a group of arc-shaped prefabricated plates 2 with vertical holes, and a ring-shaped concrete is cast in place between the prefabricated plates and the foundation. The beam 3 connects the two together, and a group of the arc-shaped prefabricated panels are connected in the circumferential direction to form a cylindrical shape through the connection of the cast-in-place concrete columns 32, and the upper and lower panels of the prefabricated panels connected in the height direction are present between the upper and lower panels. The annular concrete beams 31 are poured and consolidated up and down. The cast-in-situ annular concrete beams 31 and the cast-in-situ concrete columns 32 together form a vertical and horizontal cylindrical frame structure.

Embodiment 2

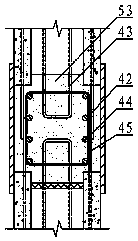

[0053] In the frame-type concrete cylindrical silo described in Example 1, the prefabricated panel has reinforcement mesh 4 composed of transverse reinforcement and longitudinal reinforcement, and the transverse reinforcement has transverse connection reinforcement extending out of the prefabricated panel. 41. The longitudinal reinforcement bars have longitudinal connection reinforcement bars 42 extending out of the prefabricated plate, the reinforcement meshes are arranged in parallel on the arc surfaces of the inner and outer sides of the prefabricated plate, and the transverse connection reinforcement bars are closed annular or semi-circular Ring-shaped or L-shaped or fishhook-shaped, the cavity has ribs 33, and the ribs of the prefabricated board have protruding fixing ribs 43.

Embodiment 3

[0055] In the frame-type concrete cylinder warehouse described in Embodiment 1 or 2, the cast-in-place concrete beam 31 has a ring rib 44 and a rib frame 45 consolidated with the ring rib, and the ring rib 44 is located in the On the horizontal section of the cast-in-place annular concrete beam, the rib frame 45 is perpendicular to the ring rib, the ring rib is distributed along the outer edge of the building to form a ring beam skeleton, and the ring rib is consolidated The rib frame 45 locates the ring rib in a certain interval. The height of the ring beam is 150-600mm and the width is 100-500mm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com