Washing device for riser of nautical oil-gas well

A technology for cleaning devices and risers, which is used in cleaning tools, flushing wells, wellbore/well components, etc., can solve the problems of easy "jamming, low work efficiency, etc., and achieves enhanced cleaning impact, compact structure, and solution The effect of inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

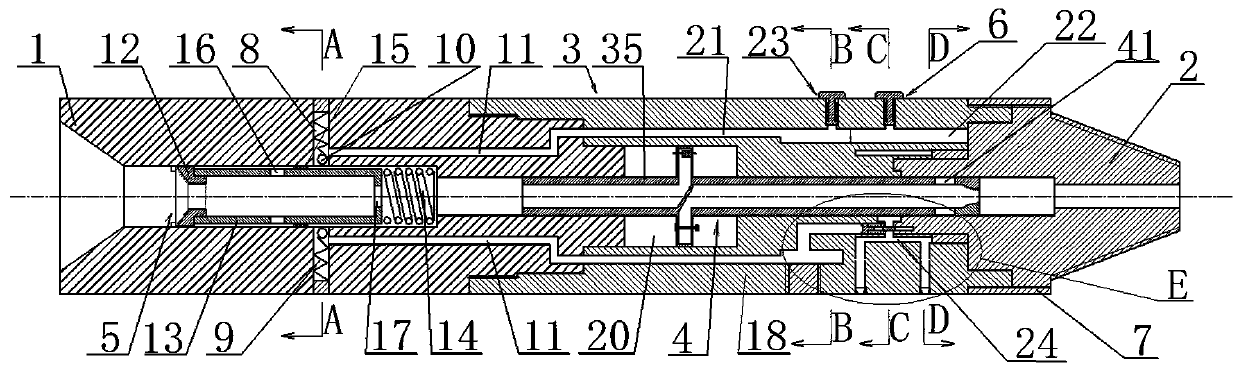

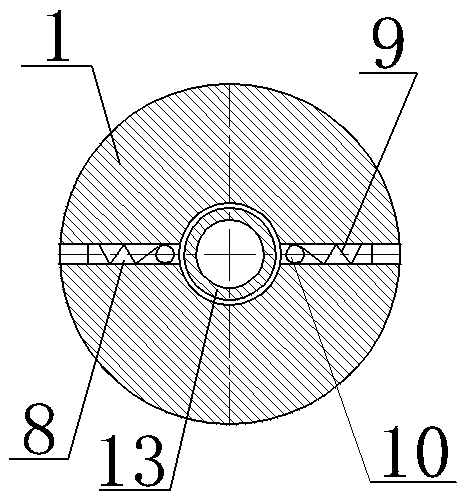

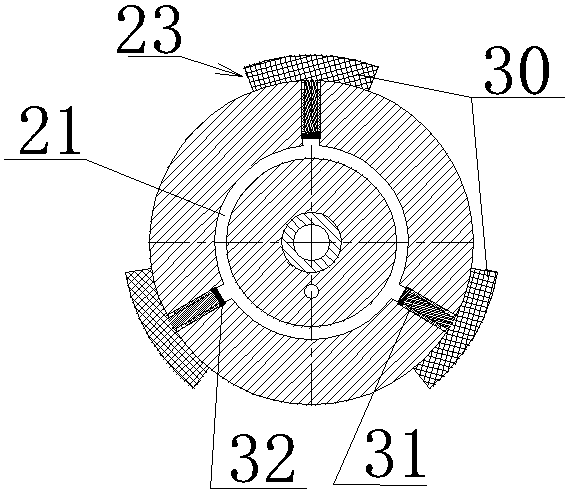

[0027] The offshore oil and gas well riser cleaning device is composed of an upper joint 1, a lower joint 2, a central cylinder 3, a reciprocating valve 4, a starting valve 5 and a connecting sleeve 7 (see the appendix figure 1 ).

[0028] One end of the central tube 3 is threadedly connected with an upper joint 1 (see the attached figure 1 ); the upper joint 1 is cylindrical; the upper joint 1 is equipped with a start valve 5 through a return spring 14 (see the attached manual figure 1 ). The starting valve 5 can slide back and forth in the upper joint 1 when it is stressed.

[0029] The starting valve 5 is composed of a sealing piston 12, a sliding sealing ring 15 and a circulation barrel 13 (see the appended figure 1 ).

[0030] One end of the flow barrel 13 is threadedly connected with a sealing piston 12; the sealing piston 12 is in the shape of a tapered ring inside; the purpose of setting the sealing piston 12 in this way is to make the high-pressure drilling fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com