In-bottle blending mixing mechanism

A technology for adjusting parts and adjusting valves, which is applied in the field of in-bottle blending and mixing mechanisms, can solve the problems that the proportioning ratio cannot meet the requirements of customers, cannot meet the output requirements of mixed liquid, and the production efficiency is low, and achieves an easy-to-understand experience. , Ingenious design, stable assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

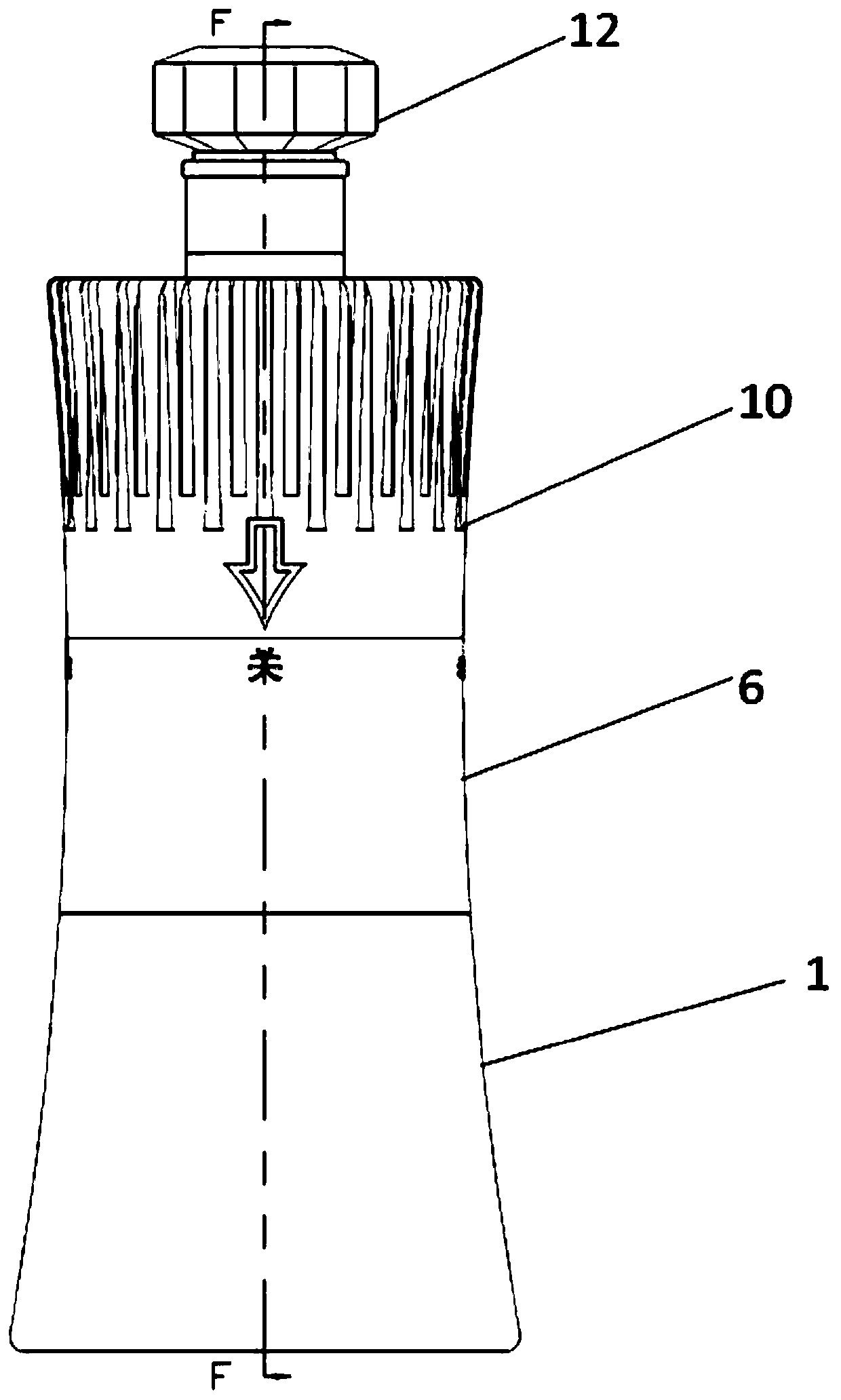

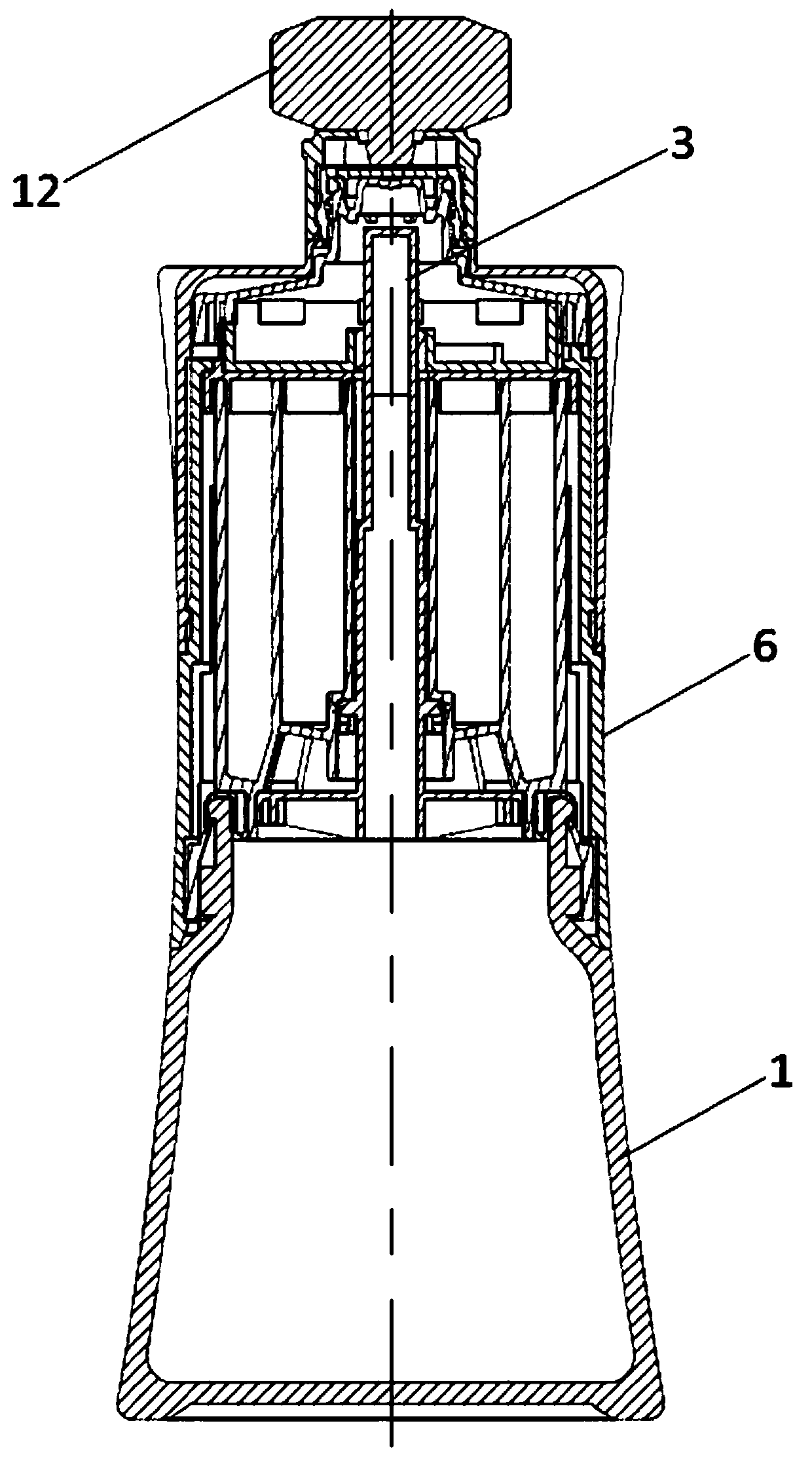

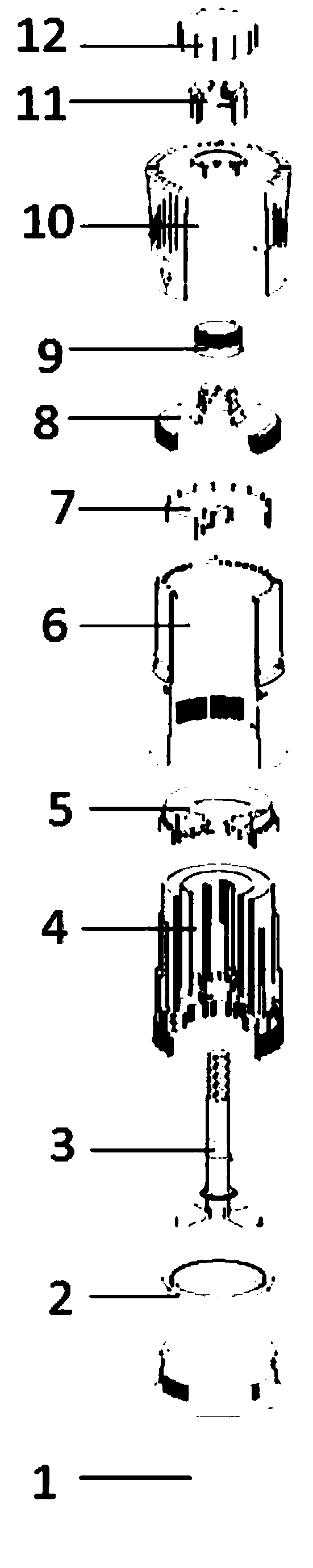

[0043] Such as figure 1 As shown, in this embodiment, an in-bottle blending and mixing mechanism is specifically provided, including an upper container 4 and a lower container 1, both of which are in a cylindrical structure, that is, the upper container 4 has two ends Open cylindrical structure, the lower container 1 is a cylindrical structure with one end open, to simplify the assembly difficulty between the upper container 4 and the lower container 1, the upper container 4 and the lower container 1 are the basic carriers for realizing the technical solution, Different fillers are filled in the upper container 4 and the lower container 1 respectively: A filler and B filler.

[0044] Such as figure 2 As shown, one end of the upper container 4 is sealed with an interlocking assembly, and the other end is hermetically assembled with the lower container 1, and under the cooperation of the interlocking assembly, the upper container 4 and the lower container 1, they together form...

Embodiment 2

[0050] Such as Figure 4 As shown, in order to realize the stable assembly between the hooking part 7 and the hooking inner plug 5 and to better operate the normal operation of the hooking part 7, it also includes a rotating part 10 and a bottle mouth 8 installed inside it, and the rotating part 10 It is also made into a cylindrical structure, and the end of the rotating member 10 can be directly sleeved on the end of the upper container 4 (for example: the most conventional buckle and ring groove can be used), and the rotating member 10 rotates During the movement, the hooking part 7 is linked with the bottle mouth 8 to make a rotary motion. During the movement of the hooking part 7, the inner ring cavity and the outer ring cavity can be communicated with the bottle mouth 8 respectively or simultaneously, so as to continuously switch the inner ring cavity and the outer ring cavity. In the open or closed state of the outer ring cavity, at the same time, the hook adjustment par...

Embodiment 3

[0055] Such as Figure 5 , Figure 15 As shown, on the basis of the above-mentioned embodiment 1 and embodiment 2, in order to further improve the assembly stability and assembly difficulty between the rotating member 10, the interlocking assembly, the upper container 4 and the lower container 1, it also includes the The connecting piece 6 outside the above-mentioned container 4, one end of the connecting piece 6 is sleeved in the rotating piece 10 and the end is provided with a connecting piece anti-reset boss 21 and two connecting piece shrapnel 20, and the other end part is socketed with the lower container 1; the end of the bottle mouth 8 facing the connecting piece 6 is provided with a bottle mouth stopper, under the action of the bottle mouth stopper and the elastic piece 20 of the connecting piece, the rotation direction of the rotating member 10 can be limited , in order to play the role of anti-counterfeiting, under the action of the anti-reset boss 21 of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com