Large-span flue and construction method thereof

A large-span, flue technology, applied in the direction of combustion methods, combustion product treatment, exhaust gas devices, etc., can solve the problems of restricting the layout and application of process flow, increasing the difficulty of design and construction cost, and the large proportion of flue space , to achieve the effect of ensuring stability and economy, improving convenience and reducing the self-weight of the flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

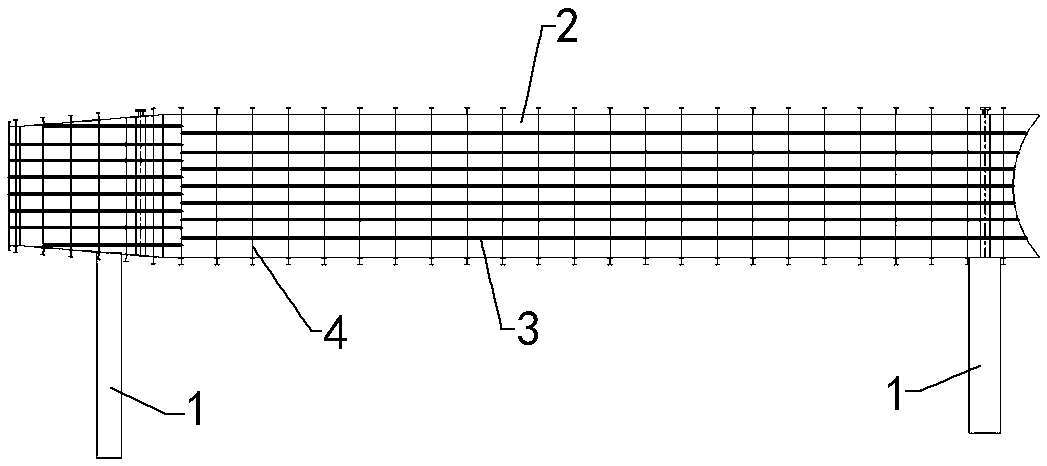

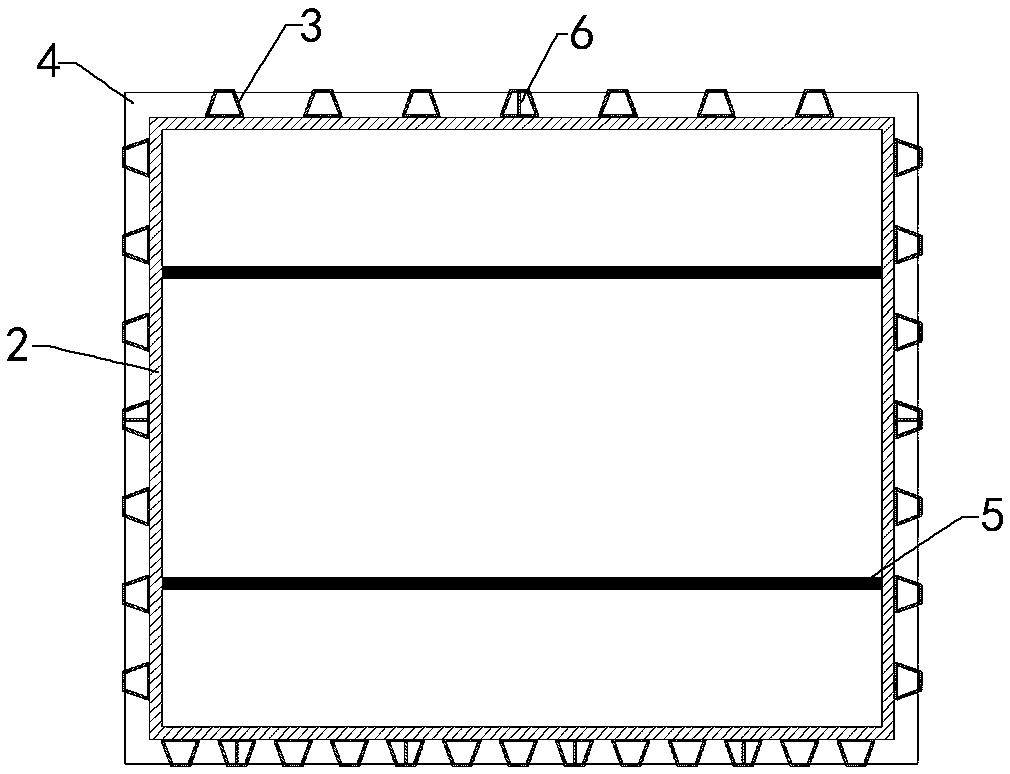

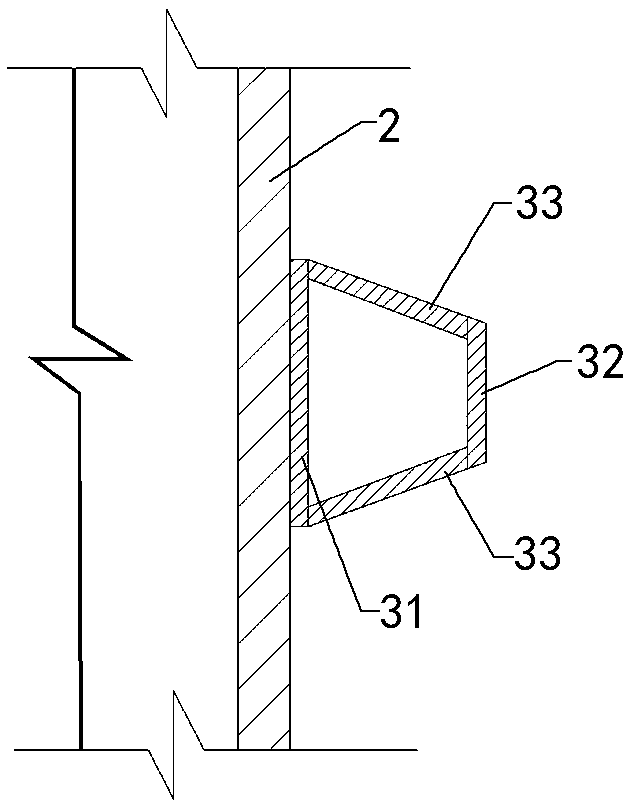

[0038] Such as Figure 1 to Figure 4 As shown, in the large-span flue of the present invention, support frames 1 are provided at the bottom of both ends, the flue includes a flue wall plate 2, a longitudinal rib 3 arranged along the flue gas flow direction, and a ring rib arranged around the outer wall of the flue 4, and the support rod 5 arranged in the flue.

[0039] The ratio of the width to the height of the flue section is not greater than 1:2, the span of the flue is not less than 35m, the span of the flue is 4-6 times the height of the section of the flue, and the flue wall 2 is composed of an upper wall and a lower wall It is a rectangular structure enclosed by side panels on both sides. The upper panel, lower panel and side panels are all steel plates with a thickness of not less than 6mm. When the temperature of the flue gas flowing through the flue is not higher than 180°C , use Q235B steel plate, when the temperature of the flue gas flowing through the flue is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com