Automatic feeding device for molten metal smelting and operation process

An automatic feeding device and molten metal technology, applied in the field of casting, can solve the problems of poor quality of molten iron, the influence of the addition time on the pouring process, and the inability to accurately control the amount of addition, so as to avoid cumbersome and repetitive operations, save physical labor, and achieve accurate weighing. Quantity and the effect of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical solution of the present invention more clearly, it will be described in detail according to the embodiments of the accompanying drawings. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. For those of ordinary skill in the art, without paying Under the premise of creative work, other structural forms or combinations can also be obtained according to these drawings.

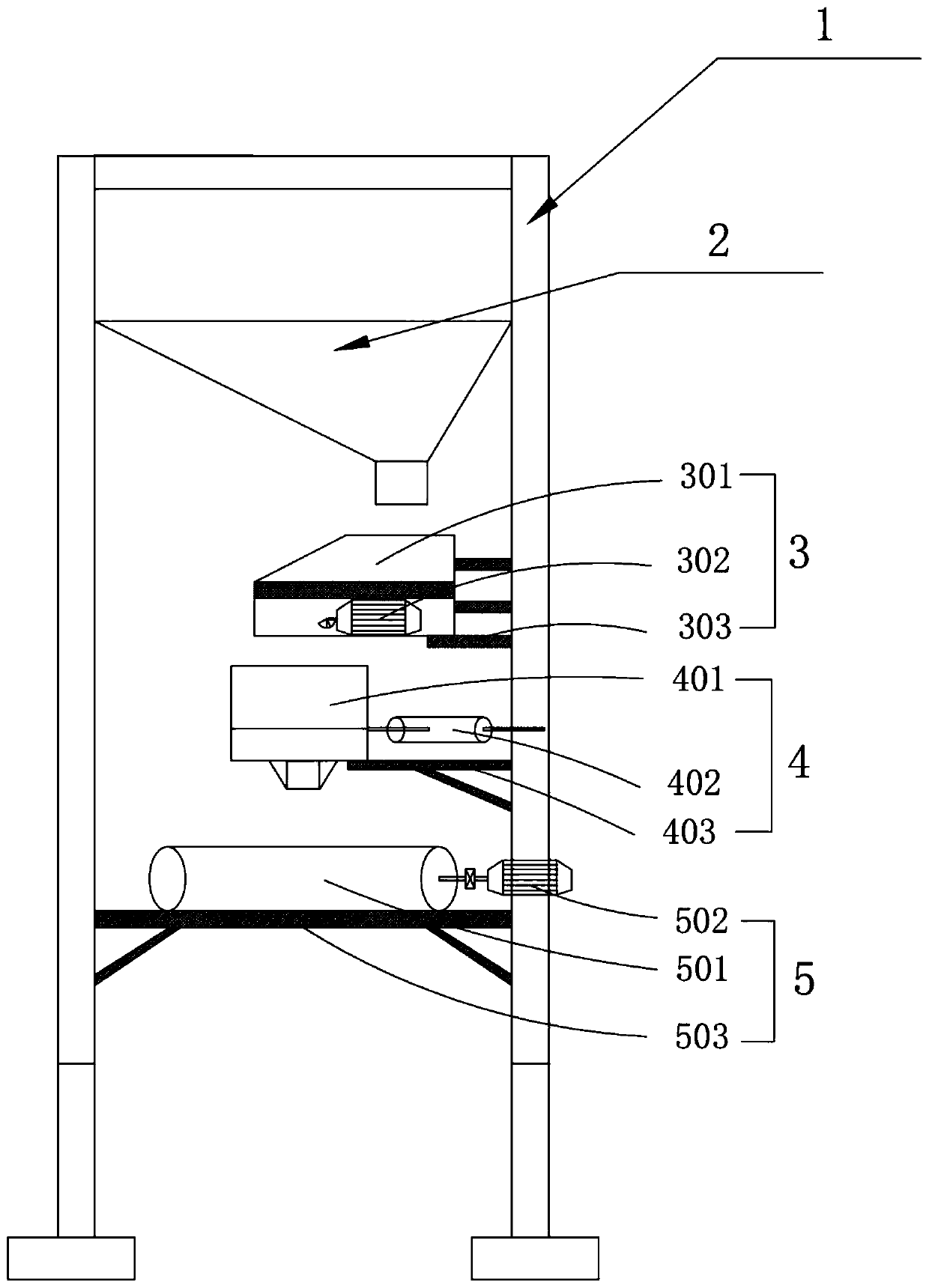

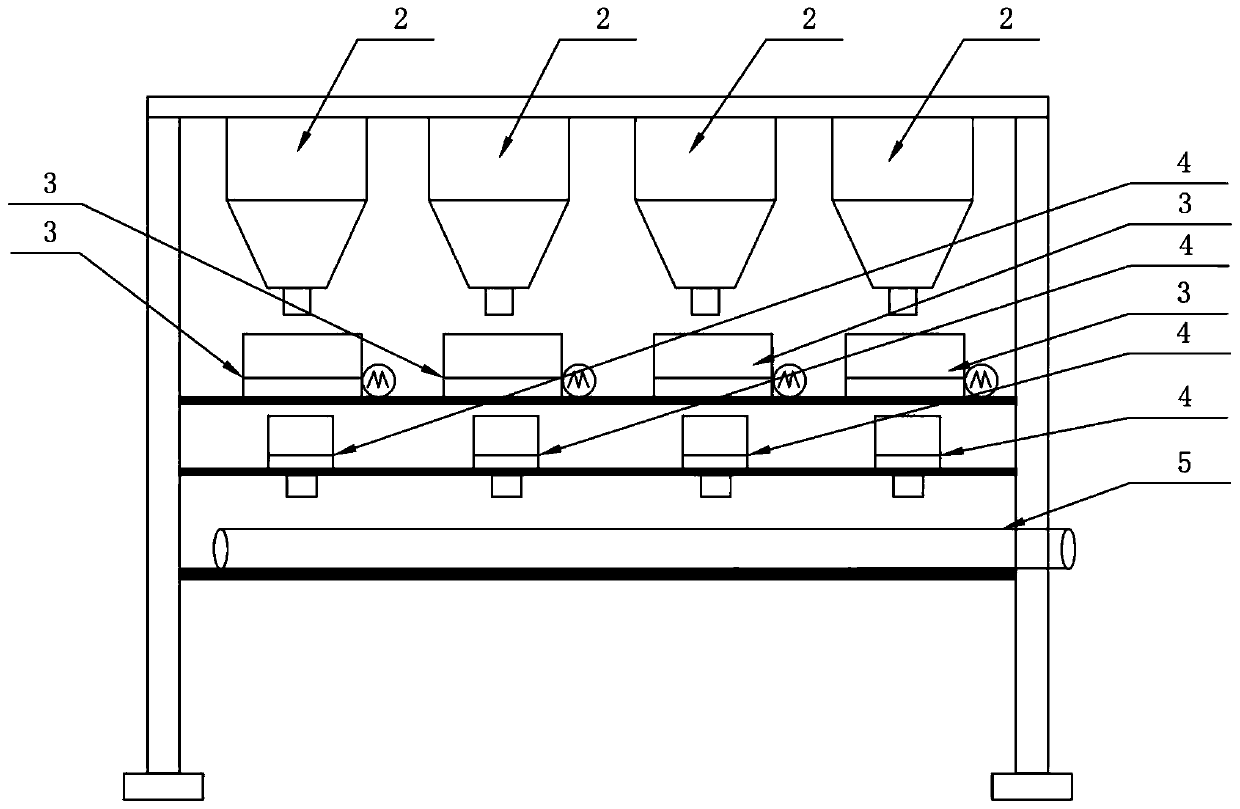

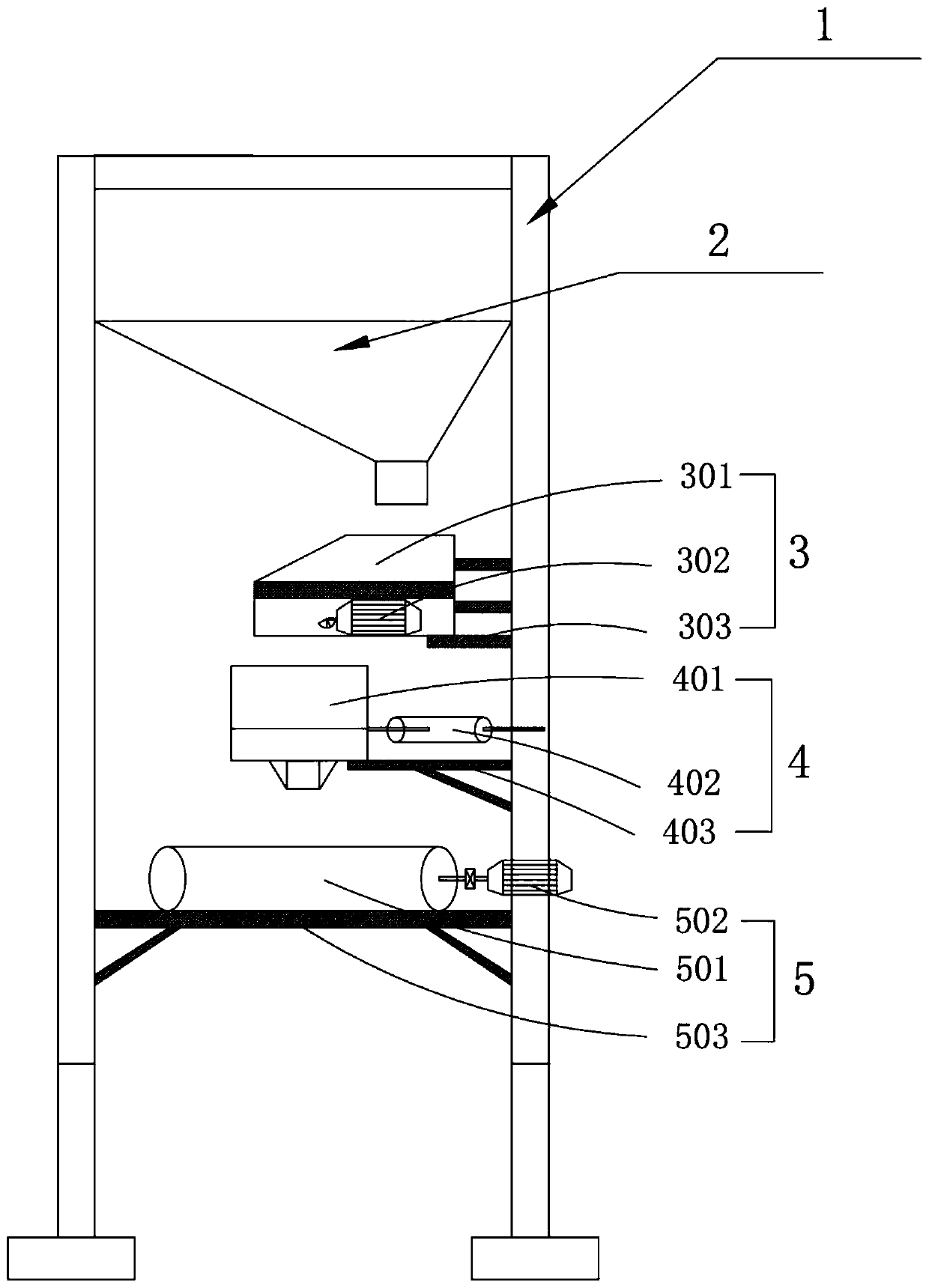

[0025] Such as figure 1 and figure 2 The shown automatic feeding device for molten metal smelting includes a frame 1, an alloy storage hopper 2, a vibrating feeding part 3, a weighing part 4 and a feeding part 5, and the alloy storage hopper 2, the vibrating feeding part 3, The weighing part 4 and the material delivery part 5 are arranged from top to bottom on the frame 1, wherein the feed inlet of the alloy storage hopper 1 is placed on the rectangular frame at the top of the frame 1, and the material deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com