Inflating and deflated device for a thin-walled sealed cylinder

A sealing cylinder, inflating and deflating technology, which is used in the sealing, installation, camera body and other directions of the engine, can solve the problem that the thin-walled sealing cylinder cannot be installed with the inflation and deflation valve, etc. Guaranteed image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

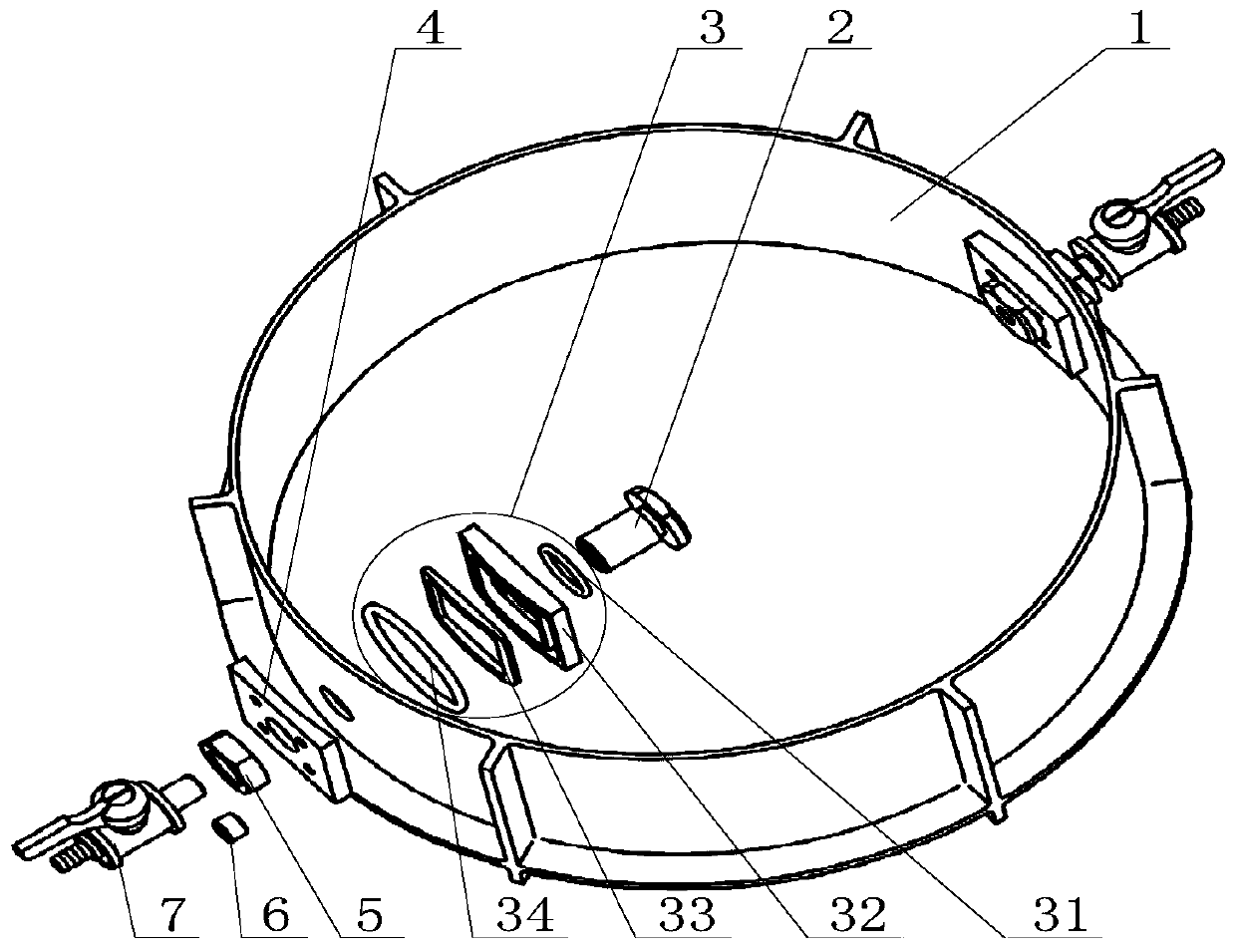

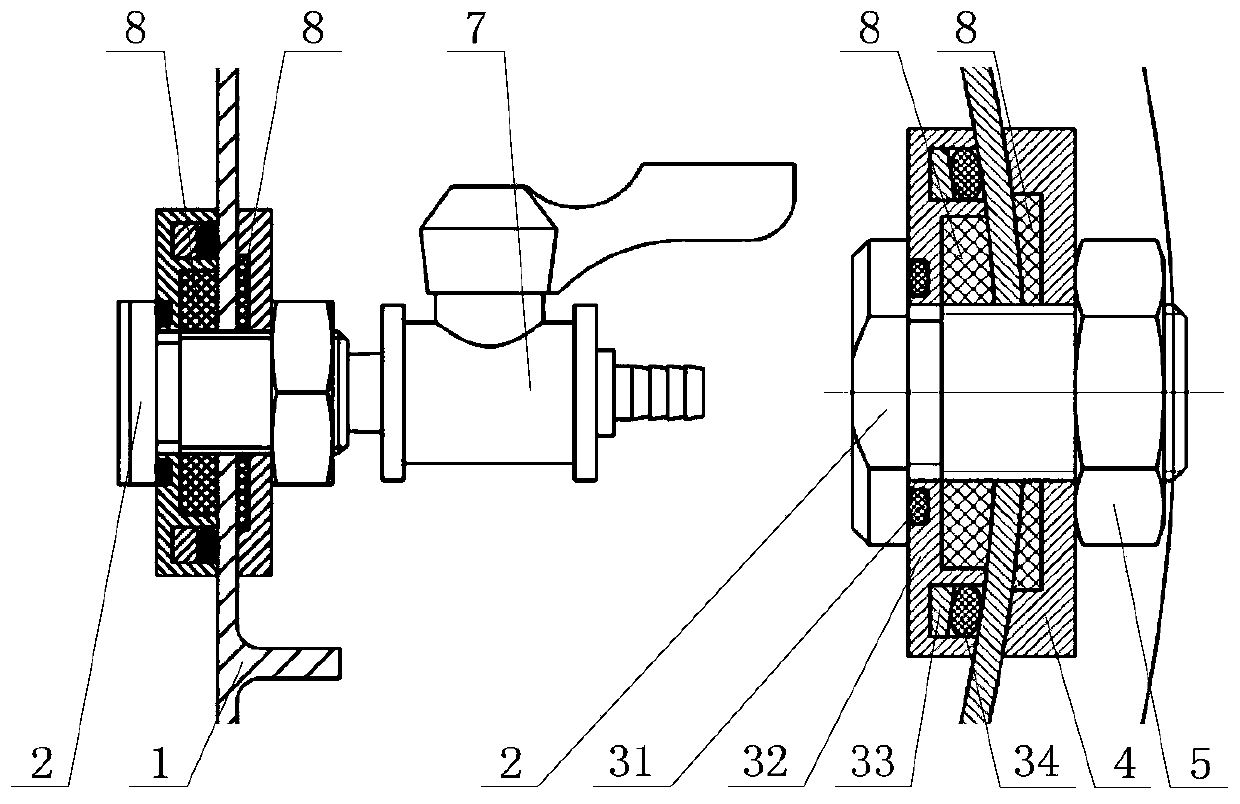

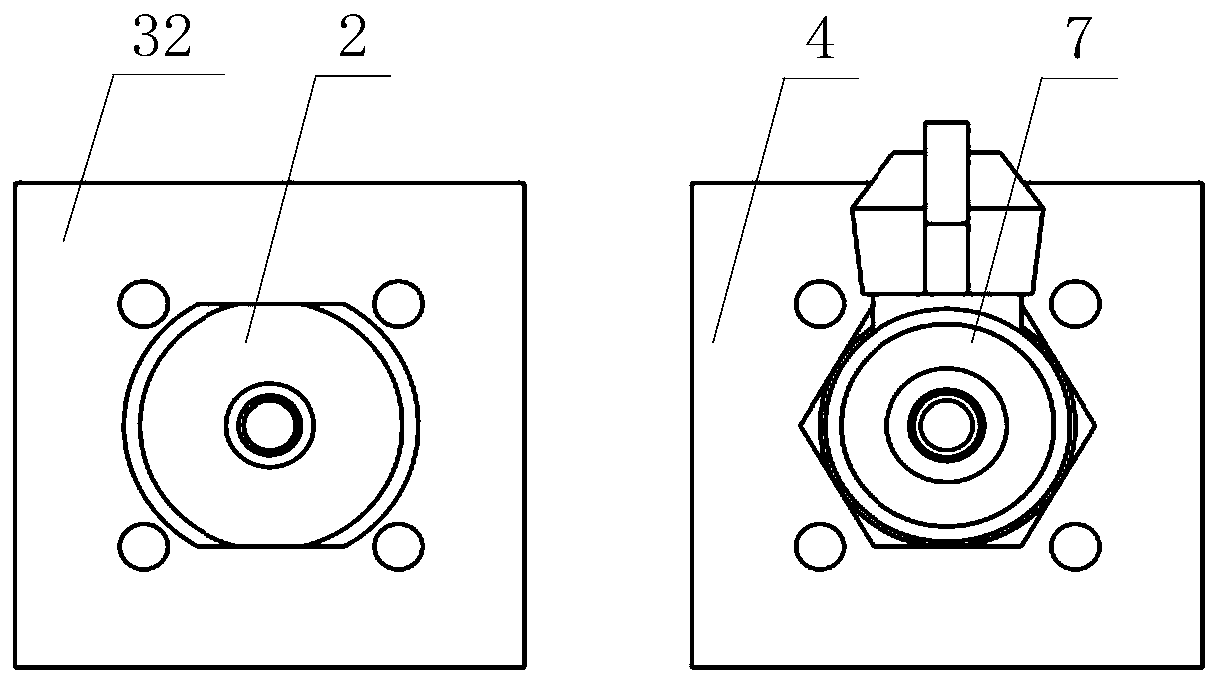

[0021] Please see attached figure 1 : A kind of inflation and deflation device applied to thin-walled sealing cylinder is installed on the cylinder wall of thin-walled sealing cylinder 1, including fixed shaft sleeve 2, inner sealing assembly 3, outer sealing gasket 4, nut 5, conical counterbore screw plug 6 and valve 7. The fixed shaft sleeve 2 is in the shape of a nut fixed at one end and a bolt with external threads on the pipe surface at the other end. In order to make the thin-walled sealing cylinder 1 have the function of charging and deflation, it is necessary to install two inflation and deflation valves on it. The device has air intake at one end and air outlet at one end. In order to enable the present invention to be installed on the thin-walled sealing cylinder 1, two through holes need to be processed on the thin-walled sealing cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com