Tension string applicable to adjusting wire length

A technology of tension string and adjustment line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

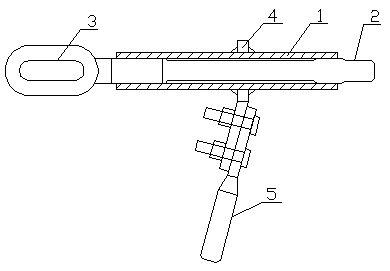

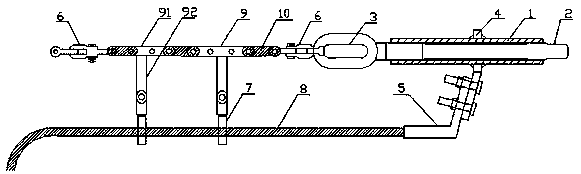

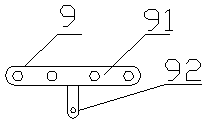

[0038] Such as Figure 6 Shown: take a kind of strain string that is suitable for adjusting the line length of the present invention to be applicable to two split wires 2 as an example:

[0039] The connecting device 6 includes hanging point fittings 21, a first U-shaped hanging ring 22, an adjusting plate 23, a connecting plate 24, an adjusting traction plate 25, a first right-angle hanging plate 26, an insulator 27, and a bowl head hanging plate 28 connected in sequence. , hanging plate 29, the second U-shaped hanging ring 210, a variable two connecting plate 211, the second right-angle hanging plate 212, the third U-shaped hanging ring 213 and the fourth U-shaped hanging ring 214; wherein, the hanging point hardware 21 is connected to the tower, the third U-shaped hanging ring 213 is connected to the level adjustment device, and the fourth U-shaped hanging ring 214 is connected to the tension clamp;

[0040] Take the upper wire 2 of the two-split wire 2 as an example:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com