Power factor correction circuit and air conditioner

A power factor correction and circuit technology, applied in emergency protection circuit devices, output power conversion devices, instruments, etc., can solve problems such as poor practicability, and achieve the effect of boosting and power factor improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

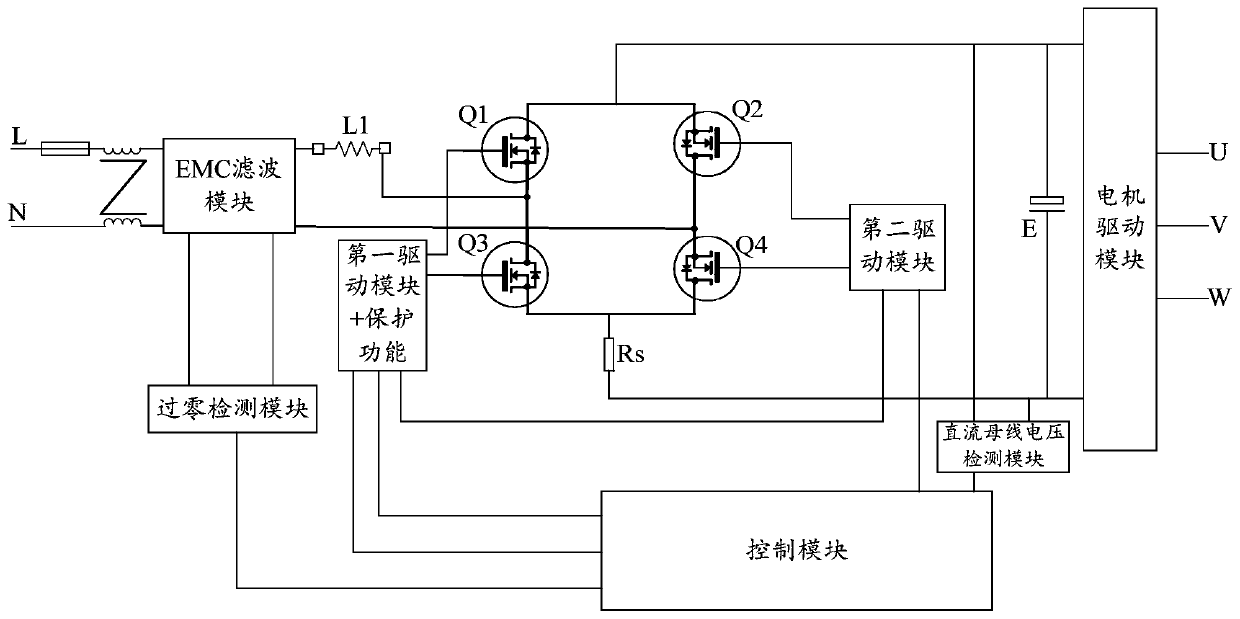

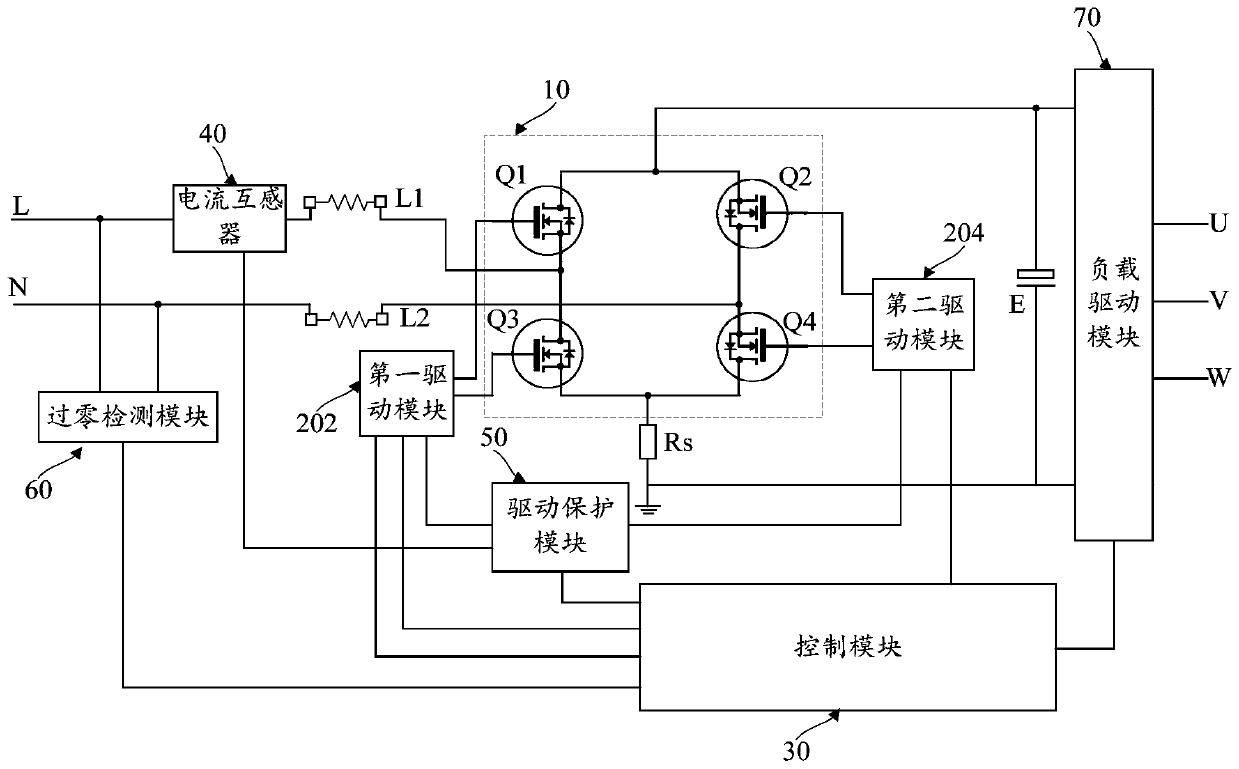

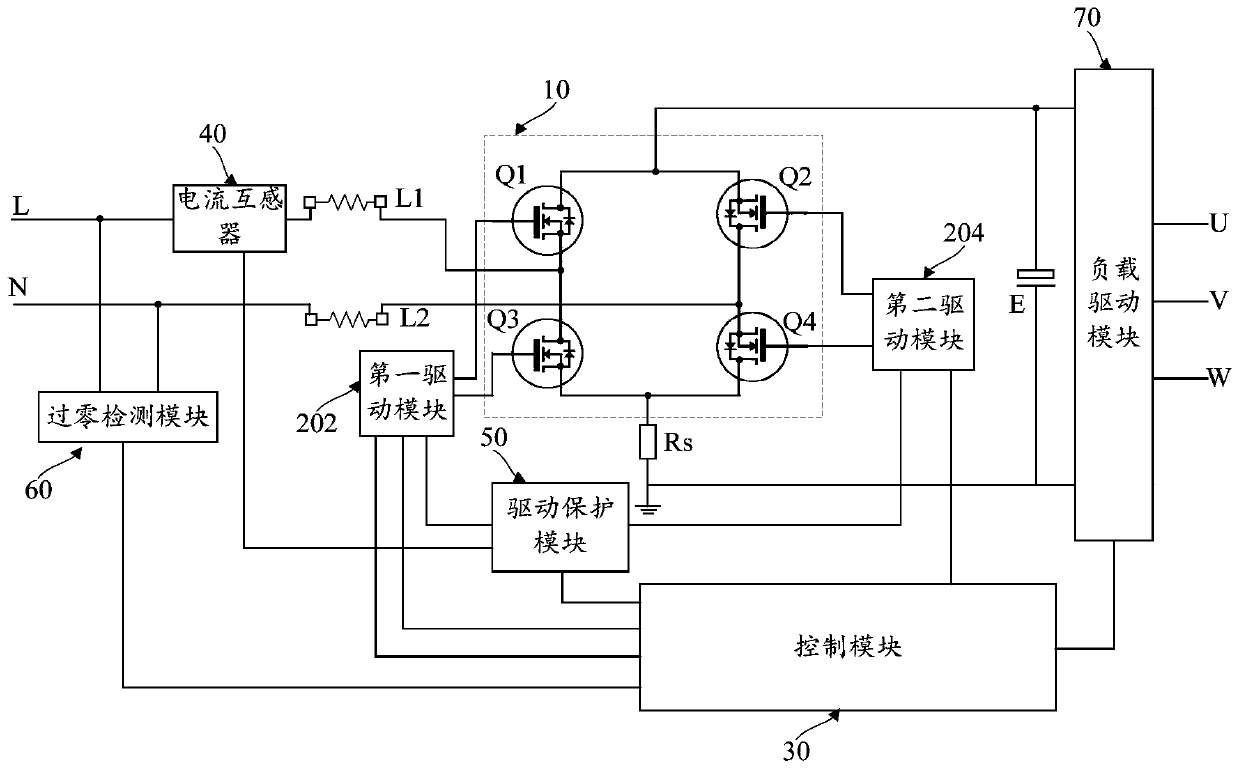

[0055] Such as figure 2 As shown, the power factor correction circuit according to an embodiment of the present invention is suitable for an air conditioner, and includes: a power factor correction module 10 for receiving a power supply signal, the power factor correction module 10 includes a switching tube, and the switching tube is configured In order to control the power supply signal to supply power to the load; the driving module is connected to the driving input end of the switching tube, and is used to output the switching signal to the switching tube; the control module 30 is connected to the driving module, and is used to control the switching tube The drive module turns on and outputs the switch signal or closes the output of the switch signal; the current transformer 40 is arranged on the input side of the power factor correction module to collect sampling signals; the drive protection module 50 is connected to the current transformer And the control module is conn...

Embodiment 2

[0059] Such as figure 2 As shown, in the above embodiment, optionally, further include: a sampling resistor Rs, set at the negative output terminal of the power factor correction module 10, and connected to the drive protection module 50, the drive protection module 50 After detecting that the voltage drop on the sampling resistor Rs exceeds the second safety threshold, the control module 30 outputs the protection signal.

[0060] In this embodiment, a current transformer 40 is connected in series on the AC side of the power factor correction module 10 to be responsible for detecting the current on the AC side, and then the voltage signal output by the sensor is used as the input signal for driving the protection module 50, combined with The sampling resistor Rs connected in series at the negative output terminal of the power factor correction module 10, the voltage detected by the sampling resistor Rs is also input into the drive protection module 50, when any of the two inp...

Embodiment 3

[0067] Such as figure 2 As shown, in any one of the above embodiments, optionally, the power factor correction module 10 is formed by a first switching tube Q1, a second switching tube Q2, a third switching tube Q3 and a fourth switching tube Q4, The first switching tube Q1 and the second switching tube Q2 are arranged on the upper part of the power factor correction module 10, the third switching tube Q3 and the fourth switching tube Q4 are arranged on the lower part of the power factor correction module 10, the first switching tube Q1 and the third The switch tube Q3 is arranged on the left part of the power factor correction module 10, the second switch tube Q2 and the fourth switch tube Q4 are arranged on the right part of the power factor correction module 10, the first switch tube Q1, the second switch tube Q2, the third switching tube Q3 and the fourth switching tube Q4 both have freewheeling diodes, the drain of the first switching tube Q1 is connected in series with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com