Thin cover film with EMI function

A covering film and functional technology, applied in the direction of film/sheet release liner, film/sheet adhesive, electrical components, etc., can solve problems such as difficult to reach, EMI shielding film thickness and harsh shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

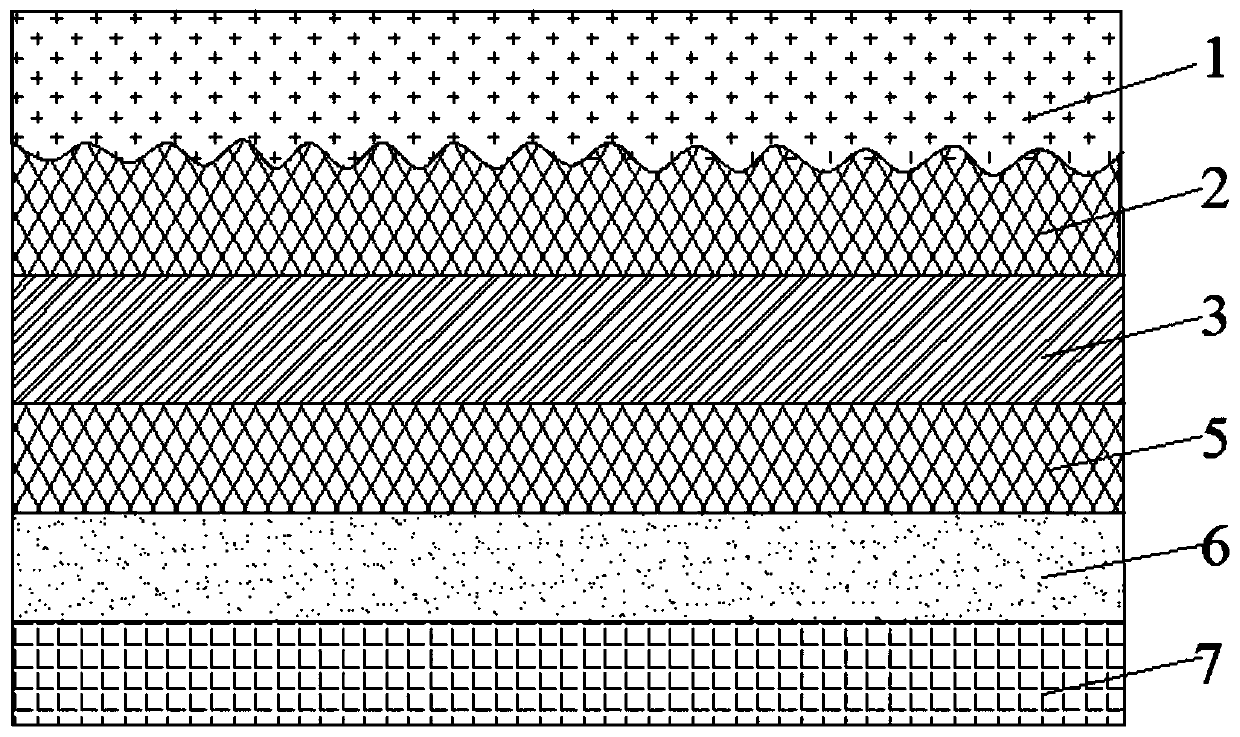

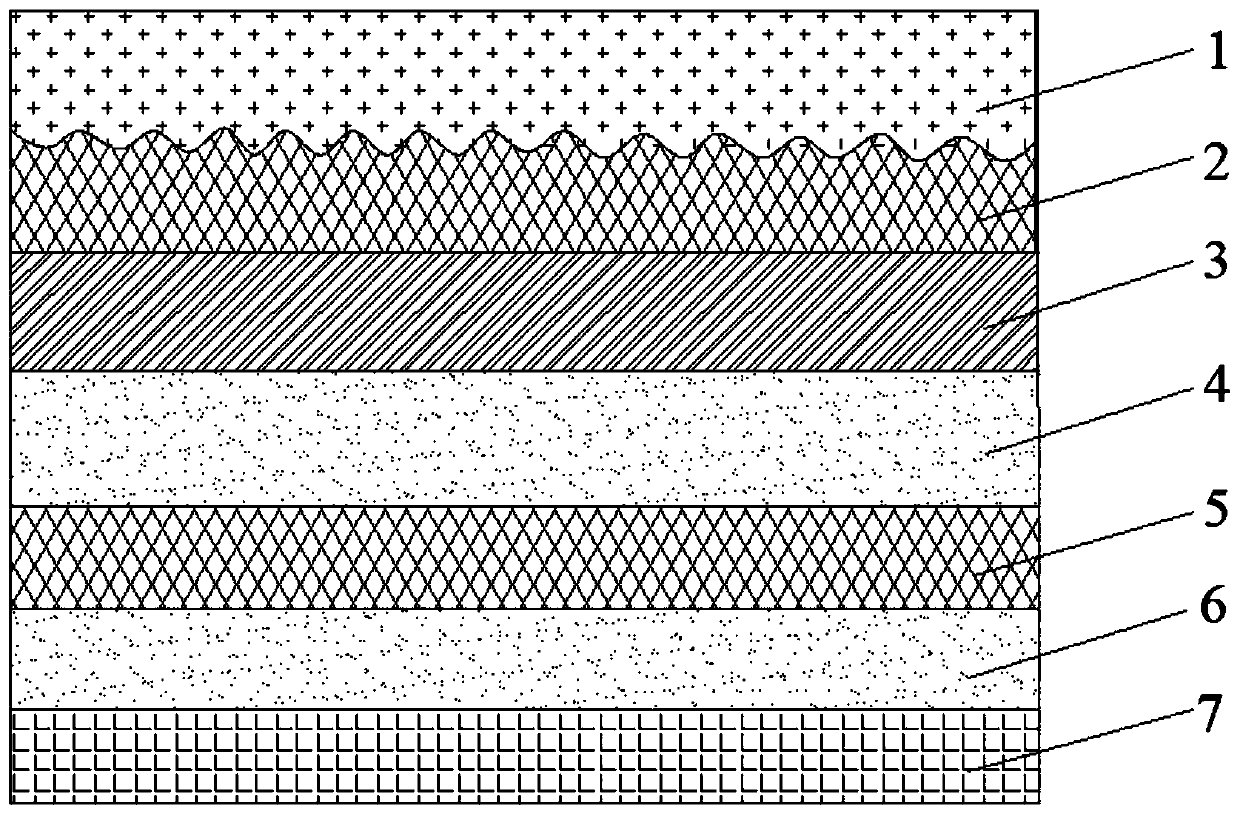

[0043] combined with figure 1 And attached figure 2 The cover film described in this application is described in further detail.

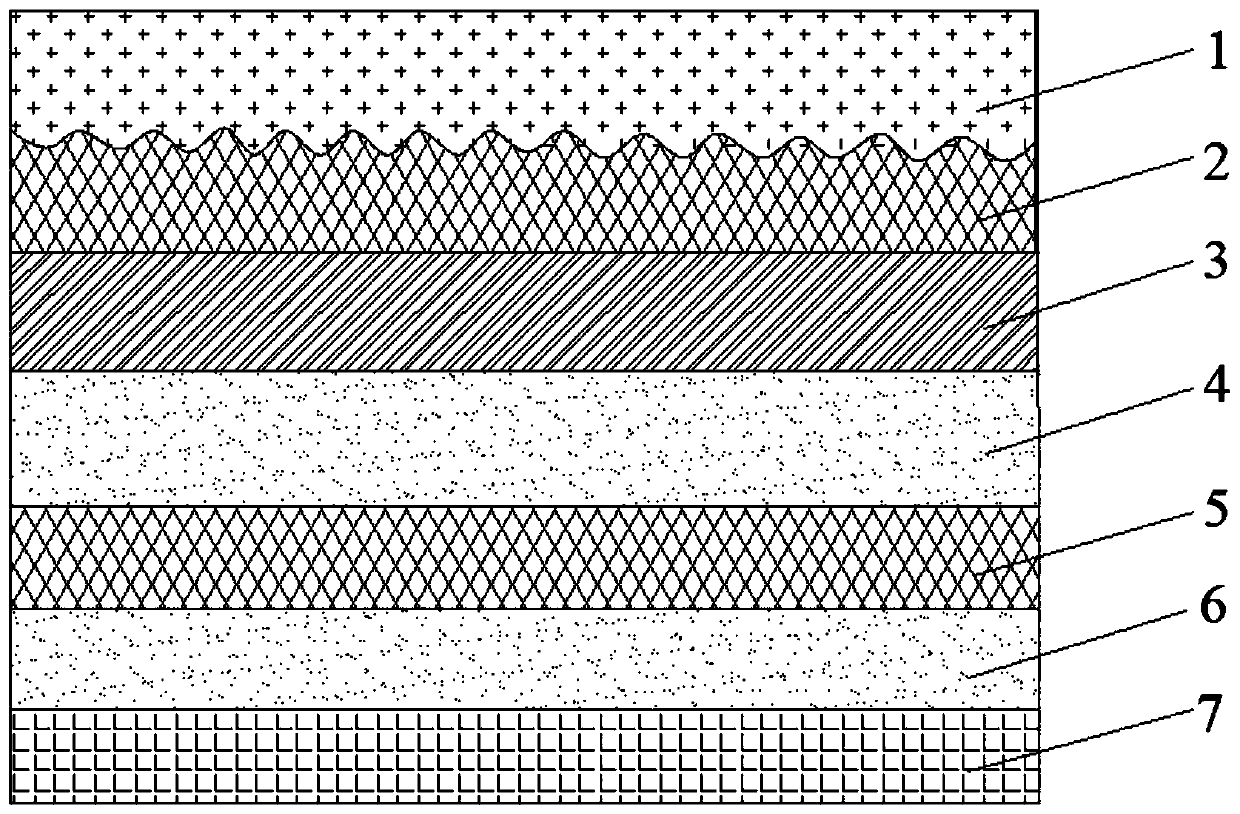

[0044] Such as figure 1 Shown is one of the cover film structures described in this application:

[0045] A thinned cover film with EMI function, comprising a stacked carrier layer 1, a first insulating layer 2, a metal layer 3, a first adhesive layer 4, a second insulating layer 5, a second adhesive layer 6 and a release layer Type Layer 7.

[0046] The thickness of the carrier layer 1 is 25-100 μm, and it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com