Dry wine raw material planting and brewing technique

A technology for drying wine and wine, applied in the preparation of wine, alcoholic beverages, biochemical equipment and methods, etc., which can solve the problems of long aging period in oak barrels, increase of oak flavor and tannin, and increase the difficulty of filtration, etc. problems, to achieve the effect of increasing soluble solid flavor substances, improving juice yield and quality, and shortening aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Production limitation: control the production of grapes and timely thin fruit. Remove the grapes with sparse and poorly developed ears, and remove the 1 / 5 of the remaining fruit at the top of the ear to ensure the uniformity and quality of the remaining fruits. The yield per mu is controlled at 300-500Kg.

[0019] 2. Water control: Strictly control the amount of water irrigation, let the roots of the vine grow downward, fully absorb the minerals in the deep soil, and increase the flavor of the grapes. The root depth requirement: 0.5m~0.8m. Irrigation timing: Irrigate in conjunction with fertilization. Judgment criteria: The leaves at the top of the tree start to wilt, irrigate immediately, water thoroughly, and stop watering after the fruit enters the color change period.

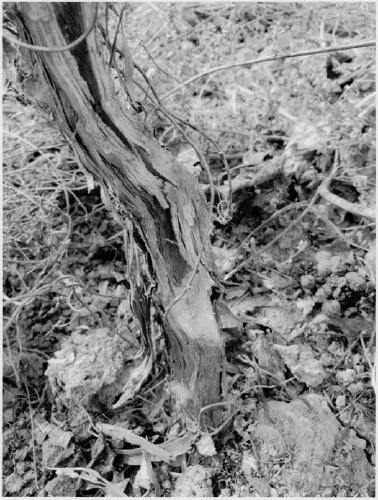

[0020] 3. Girdling: At the root of the grape vine, 10cm from the ground to the trunk, use a blade to cut around the trunk with a width of 2cm-5cm and a length of 5cm-10cm. After removing the bark,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com