Patents

Literature

36results about How to "Lower brewing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flavor barley wine and brewing method thereof

The invention relates to a flavor barley wine and a brewing method thereof. The brewing method comprises the following steps: selecting material, grinding, moistening material, stirring material, cooking, spreading and drying in the air, adding distiller's yeast to stir, moistening material again, fermenting, baking the wine, storing, blending and filtering. The invention adopts the technology combining solid natural fermentation with cooling and baking to brew the flavor barley wine, thus the liquor yield is high, the wine quality is good and nearly has no impurity; and the bitterness of thewine can be reduced by controlling the time of secondary material-moistening and the mouthfeel of the wine is good. The brewed flavor barley wine comprises the following components: 72vol.% of alcohol and 90-110g / 100mL of acid. Therefore, the demand of people for drinking the high-degree flavor barley wine can be satisfied. The brewing method of the invention can be used in Tibet, thus the brewing cost is reduced and the economic development of Tibet can be promoted.

Owner:葛庆有

Method for producing orange sparkling wine

The invention discloses a method for producing orange sparkling wine. The method comprises the following steps: controlling the orange fruit maturity; performing scald peeling, peeling, pulping and juicing; clarifying; and performing first fermentation and secondary fermentation. The processing shortcoming of high acid content of the orange fruit can be avoided, the special fragrance and the mouth feel of the orange fruit can be kept, the nutrient value can be stored, and simultaneously the problems of the bitter feeling of the orange wine and the poor stability of the orange sweet fruit wine can be well solved, and the harmful flavor substances can be reduced. No chemical substance such as artificial color, spice or preservative is added in the production process and the wine is completely fermented by pure juice. The orange sparkling wine produced by the method provided by the invention is in orange yellow color, thoroughly clear, tiny and lasting in bubbles, intense in fruit flavor, fresh and cool in mouth feel and prominent in orange characteristic feature.

Owner:四川华橙酒业有限公司

Steam explosion and gelatinization method of Chinese liquor raw grains

ActiveCN102127498ALoose structureContent remains constantAlcoholic beverage preparationChinese liquorBran

The invention discloses a steam explosion and gelatinization method of Chinese liquor raw grains. The steam explosion and gelatinization method comprises the following steps of: washing and soaking grains by using hot water, exhausting water and naturally air-drying to ensure that the grains fully absorb the water and have the aperture opening ratio of 93 to 95 percent and the water content of 40to 45 percent; and putting the grains into a steam explosion tank at the temperature of between 80 and 90 DEG C, introducing dry steam until the pressure in the steam explosion tank is 1.5 to 3.0MPa,adjusting steam flow, keeping the pressure for 5 to 10 minutes, opening a discharge valve of the steam explosion tank, blowing the grains in a normal pressure material-accommodating tank through steam explosion, opening a door of a material-accommodating bin until the grain materials are all discharged and the pressure of the steam explosion tank is reduced to be zero, and collecting the grain materials. The steam explosion and gelatinization method has the advantages that: through a steam explosion effect, the utilization rate of the raw materials is increased, the using amount of bran hullsis reduced, and liquor yield is remarkably improved; and by the steam explosion, methanol in the Chinese liquor can be reduced and even eliminated, so that the safety of the Chinese liquor is improved; and crushing and cooking steps are removed from the liquor making process, so environmental pollution is avoided, and labor, energy consumption, and the brewing cost of the Chinese liquor are reduced.

Owner:SICHUAN TUOPAI SHEDE WINE

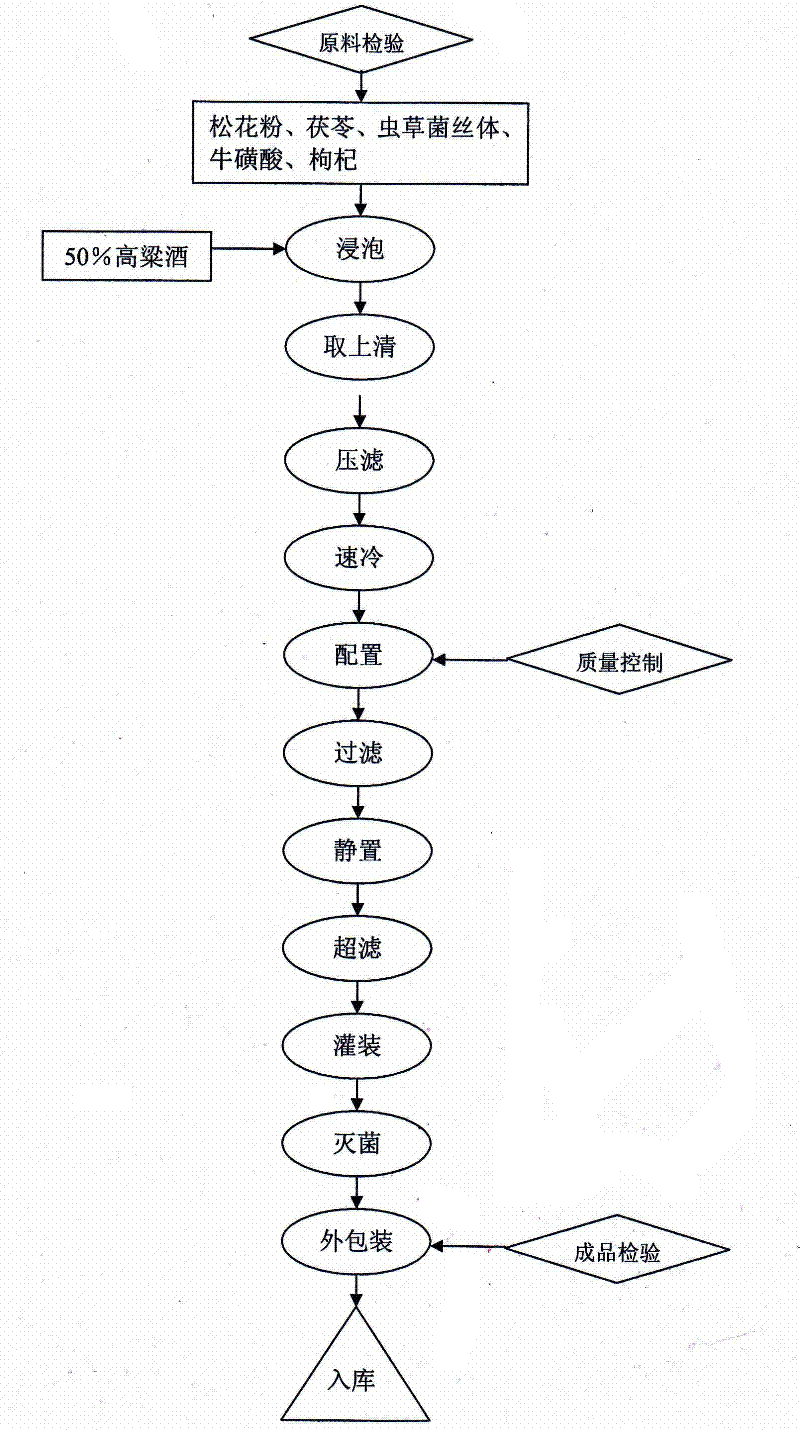

Brewing method for pine pollen wine

ActiveCN102229877AGood effectImprove efficacyDigestive systemAlcoholic beverage preparationCordycepsFiltration

The invention relates to a brewing method for pine pollen wine. In the prior art, the brewing method for the pine pollen wine has not characteristics of simple production process, low brewing cost and good efficacy of the prepared pine pollen wine. The brewing method provided by the present invention is characterized in that: raw materials of the pine pollen wine comprise: 48.0 g of broken pine pollen, 16.0 g of medlar, 24.0 g of tuckahoe, 18.0 g of mycelium of cultured cordyceps sinensis, 1.6 g of taurine, sorghum wine having a volume percent concentration of 50% and water. The method sequentially comprises processes of immersing, blending, filtering and filling. During the dipping process and the blending process, the broken pine pollen, the medlar, the tuckahoe, the mycelium of cultured cordyceps sinensis and the taurine are placed in a immersion tank, followed by adding the sorghum wine and immersing for 20-30 days to obtain supernatant; the supernatant is filtered through a pressure filtration to obtain filtrate, followed by adding water to blend the filtrate to a volume percent of 36%. During the filtering process, the filtrate from the dipping process and the blending process is filtered again to obtain the secondary filtrate, followed by standing for 48 hours to obtain half-finished product wine. The method provided by the present invention has advantages of simple production process, low brewing cost and good efficacy of the prepared pine pollen wine.

Owner:浙江亚林生物科技股份有限公司

Method for brewing cooking wine from brewer's grains

InactiveCN104026544ABrewing process is simpleLower brewing costsFood preparationChemistryNutrient content

The invention relates to a method for brewing cooking wine from brewer's grains. The method comprises the steps of: heating and steaming the brewer's grains to 28DEG C-30DEG C, adding Airpotato Yam Rhizome wine and fully stirring them to form mixed distiller's grains, the center of which is provided with a fermentation hole, conducting heat preservation at 28DEG C-30DEG C for 3 days to form yellow wine in fermentation hole, then adding warm water at 28DEG C-30DEG C in the mixed distiller's grains to conduct fermentation, performing stirring every 8 hours; and then carrying out squeezing, cooking, filtering, sealing and sterilizing, thus obtaining the cooking wine. The brewing process provided by the invention has the advantages of simplicity, low brewing cost and easy popularization. By employing brewer's grains to brew the cooking wine, the raw material sources are rich, the investment is small, the operation is convenient, and the production cost is low. On the one hand, brewer's grains replace polished rice, and on the other hand protein in brewer's grains is decomposed. Thus, nutritional ingredients in the cooking wine are increased, alcohol content of the cooking wine is enhanced, at the same time the brewer's grain resources are fully utilized, and the use value of brewer's grains is improved.

Owner:LIANYUNGANG CHUSHENGWANG FLAVORING

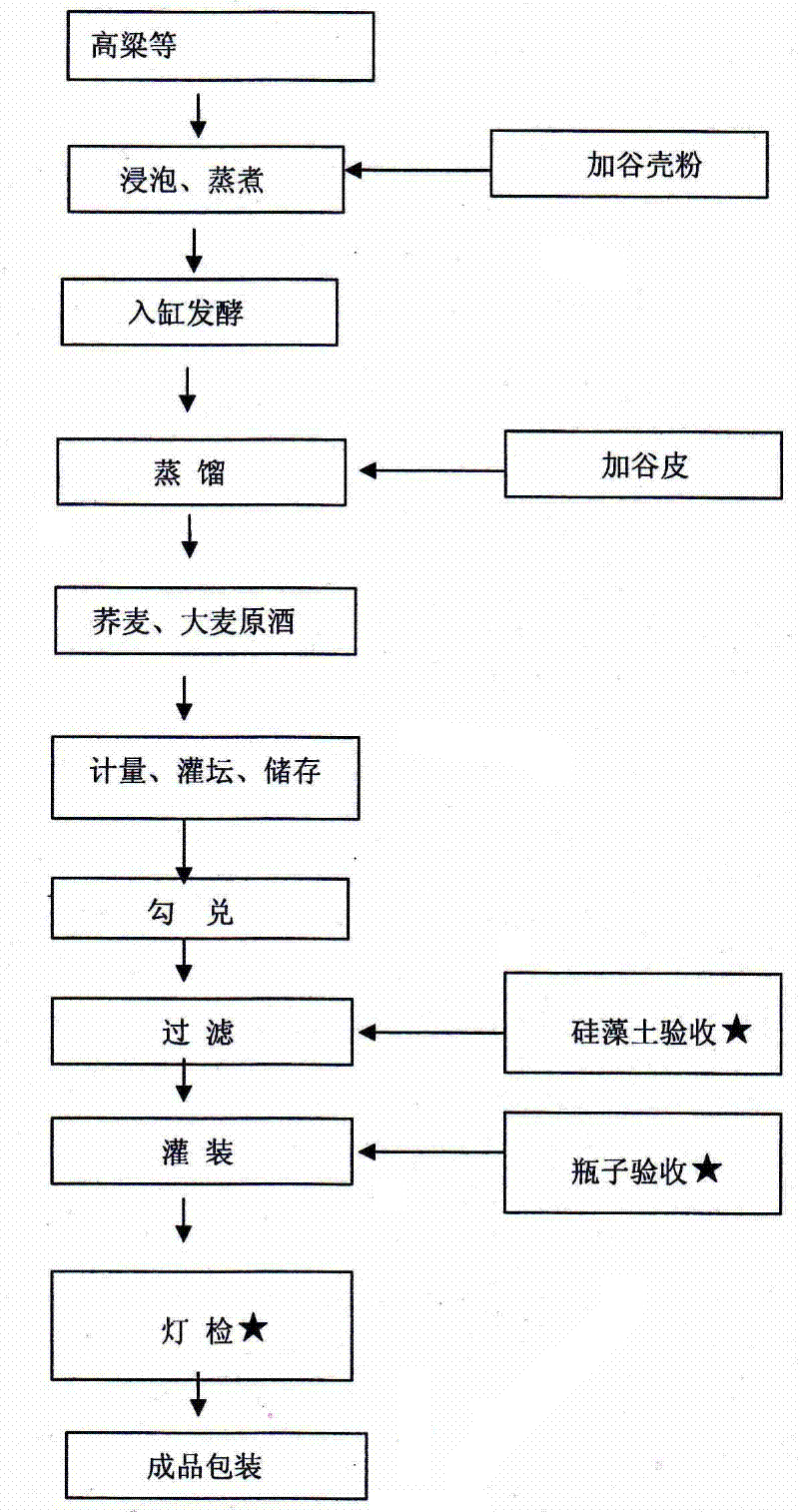

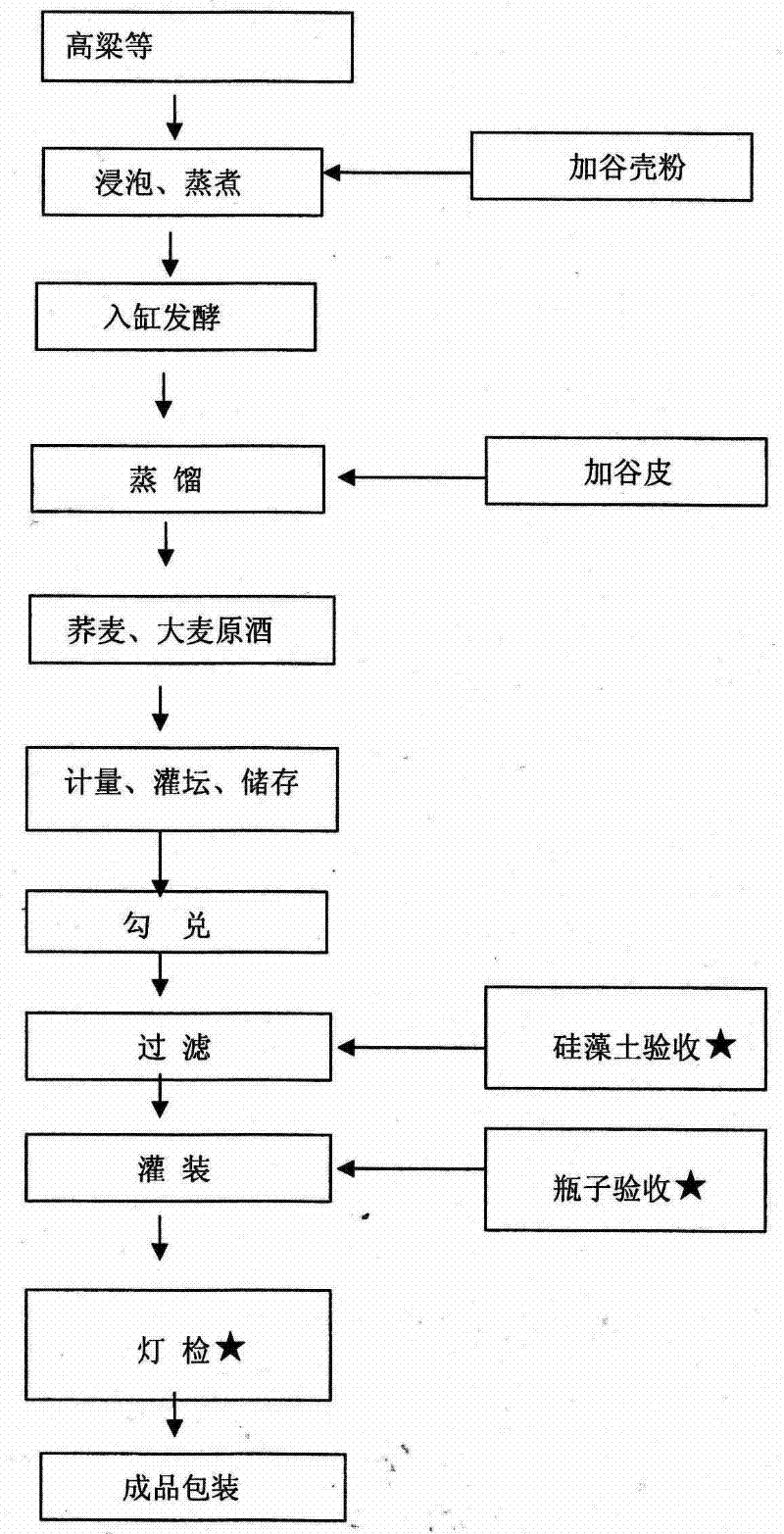

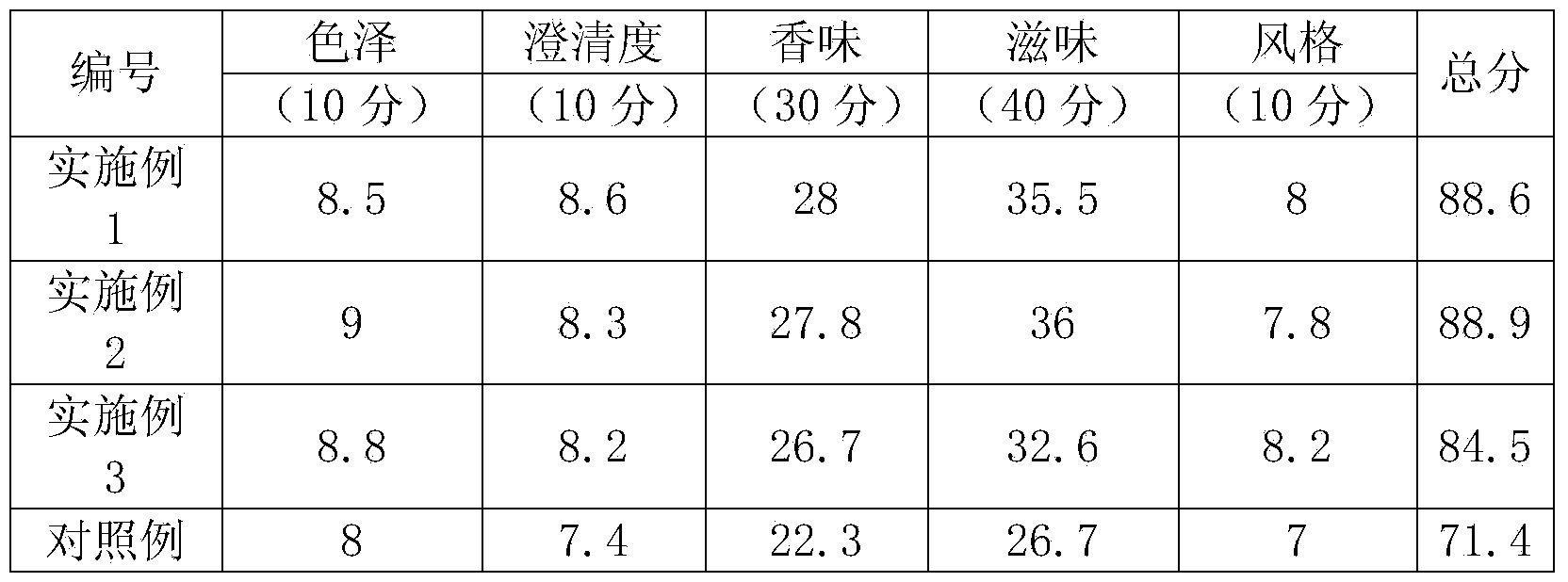

Brewing method for tartary buckwheat white spirit

The invention discloses a brewing method for tartary buckwheat white spirit. The brewing method comprises the following steps: selecting materials: selecting tartary buckwheat with good quality and full seeds; washing: cleanly washing the tartary buckwheat by mountain spring water; spraying the water and accelerating germination: pouring the washed tartary buckwheat seeds into a bamboo basket and covering by a cotton quilt to guarantee light shielding and ventilation; spraying the tartary buckwheat seeds every 4-5 hours by using warm water with the temperature of 20-25 DEG C until tartary buckwheat germs grow for 1cm-3cm; steaming: steaming the tartary buckwheat seeds in the mountain spring water and controlling the water temperature in a range of 78-82 DEG C until shells of the tartary buckwheat seeds are opened; drying: fishing out the steamed tartary buckwheat and cooling to 25-30 DEG C; adding apple butter; fermenting: fermenting for 15 days by using a yeast in a sealed manner; and distilling: taking the tartary buckwheat out and distilling to obtain base liquor of the tartary buckwheat white spirit. The tartary buckwheat white spirit brewed by the brewing method disclosed by the invention has good color luster, clarity, flavor, taste, style and the like; particularly, the apple butter is added so that the tartary buckwheat white spirit is mellow and tasty.

Owner:酉阳县荞丰农产品开发有限公司

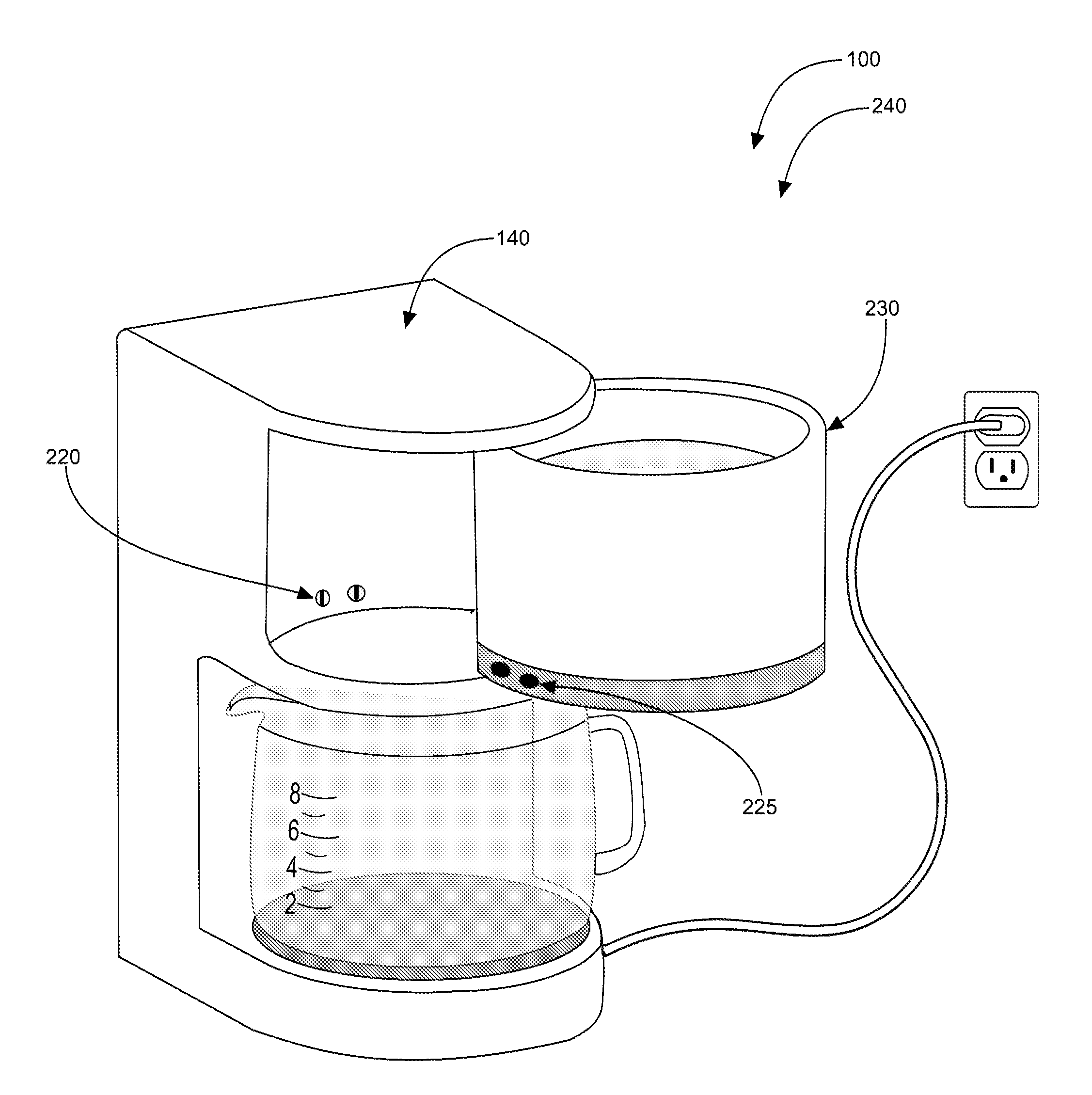

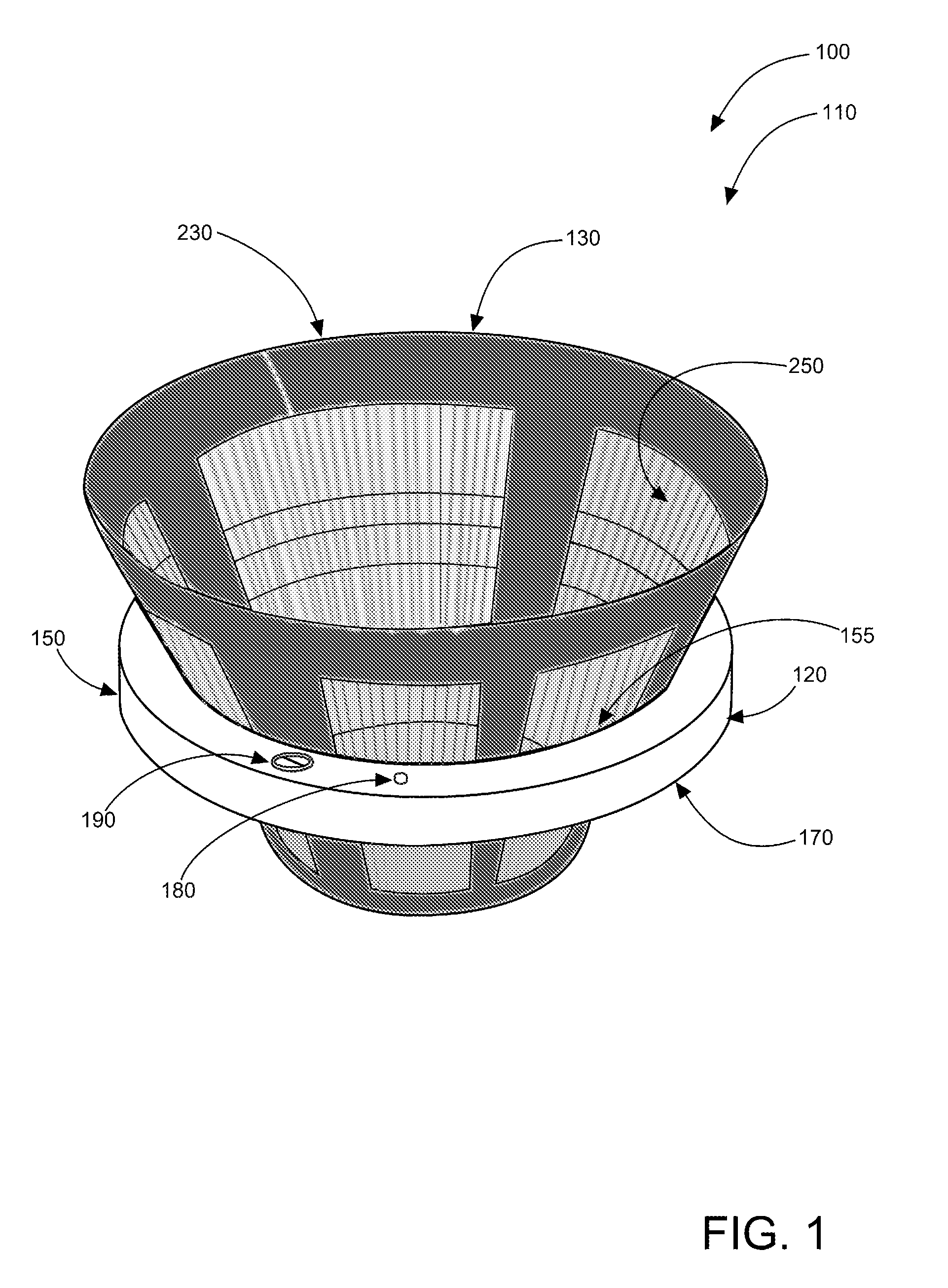

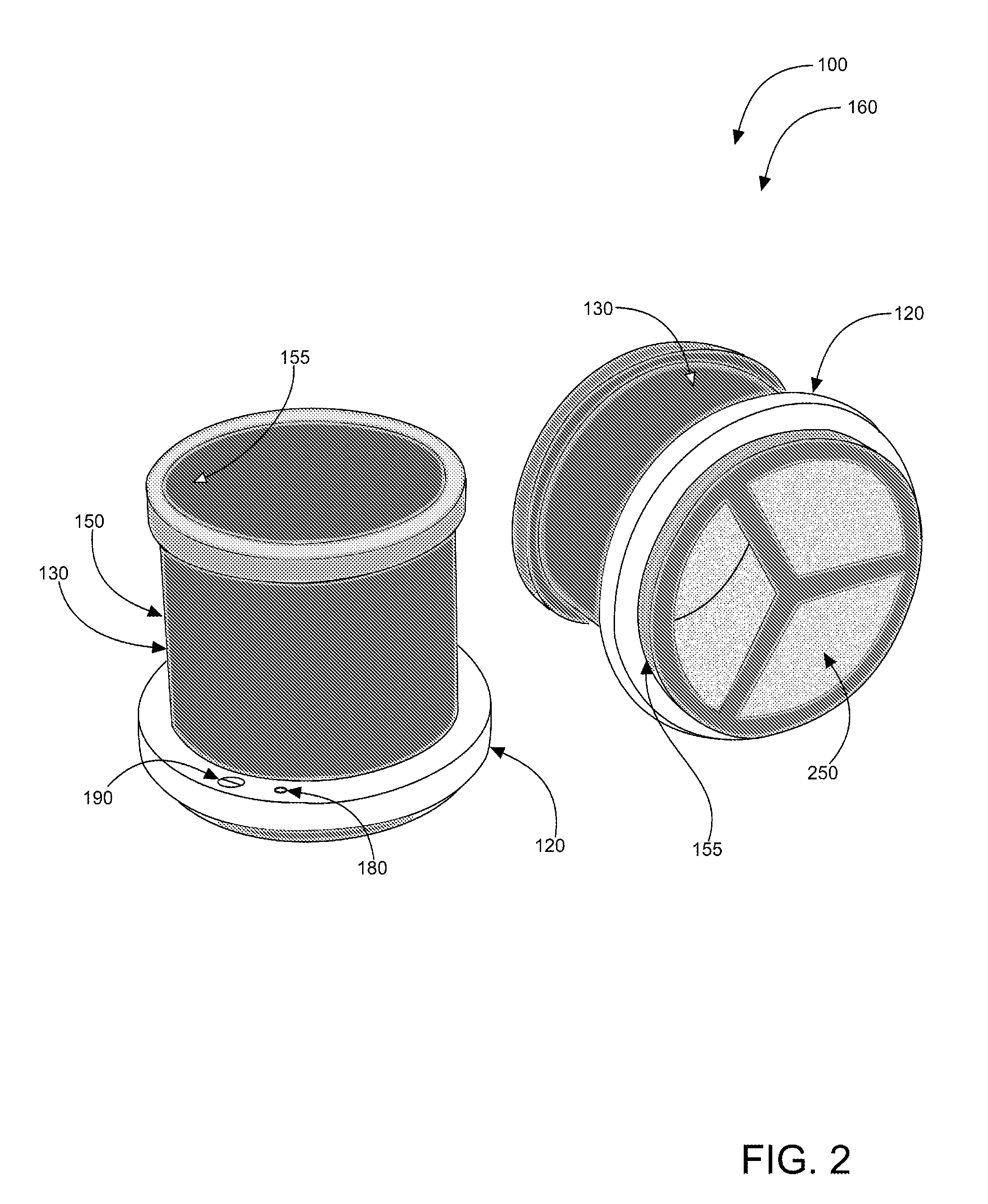

Ultrasonic brew technology systems

Ultrasonic Brew Technology Systems is a coffee brewing system with a brew ring having the capability of emitting ultrasonic waves for use in agitation of coffee grounds during a coffee brewing episode. Ultrasonic Brew Technology Systems utilizes low voltage direct current to power the circular brew ring which may be comprised of stainless steel. The brew ring may frictionally-fit about the periphery of a brewing basket of a coffee maker (on an outside circumference of the periphery of a brewing basket of a coffee maker or on / in the inside periphery.) Agitation of the coffee grounds by the ultrasonic circular waves creates an increased pulsated-distance between each of the coffee granules thereby creating a greater surface area contact between the water and the coffee grounds, creating higher efficiency and fuller flavored coffee. The brew ring may frictionally-fit about the periphery of a brewing basket of a coffee maker (on an outside circumference of the periphery of a brewing basket of a coffee maker, on / in the inside periphery), or integrated seamlessly into the “pull-out” / “swing-out” basket.

Owner:FIGURA MARK

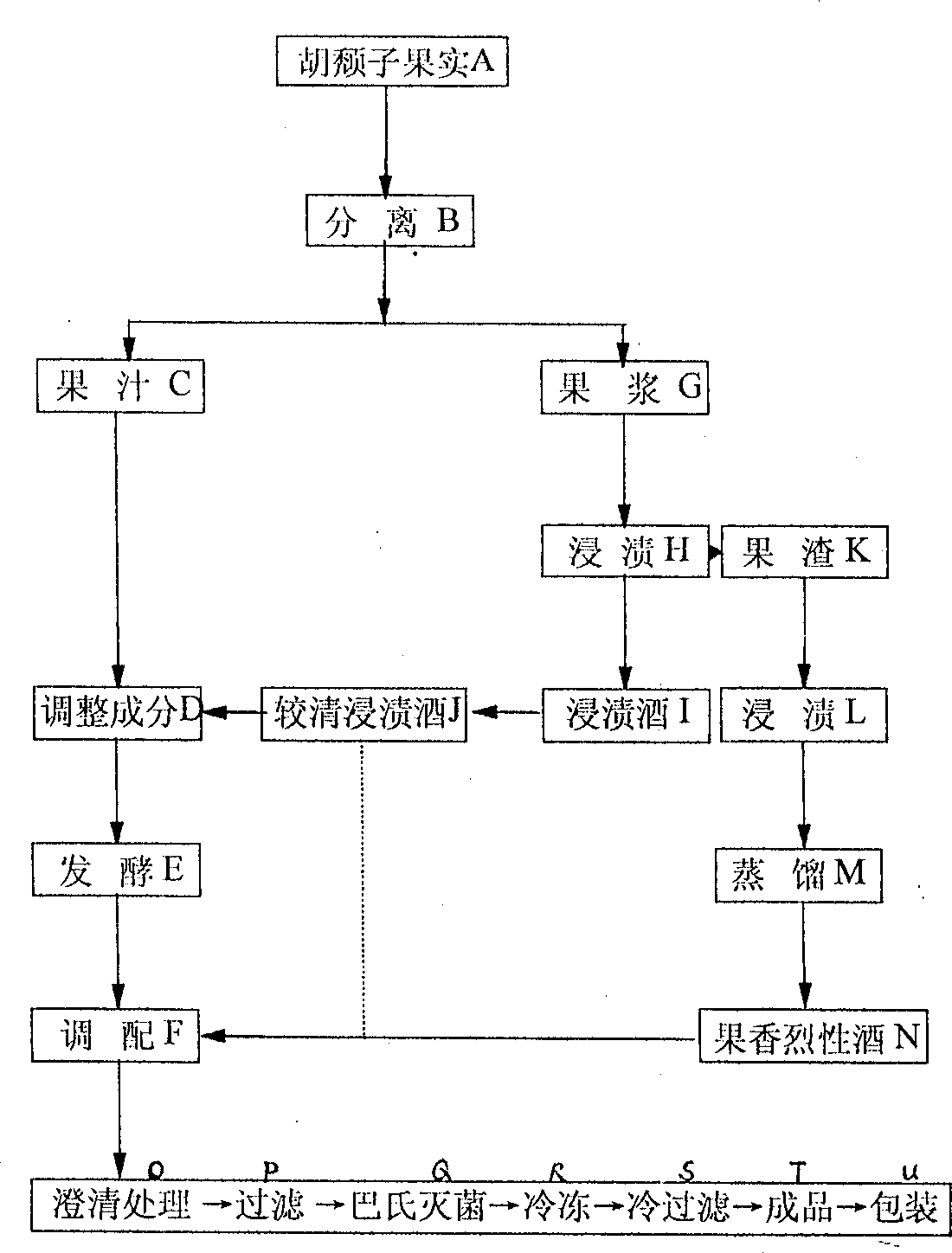

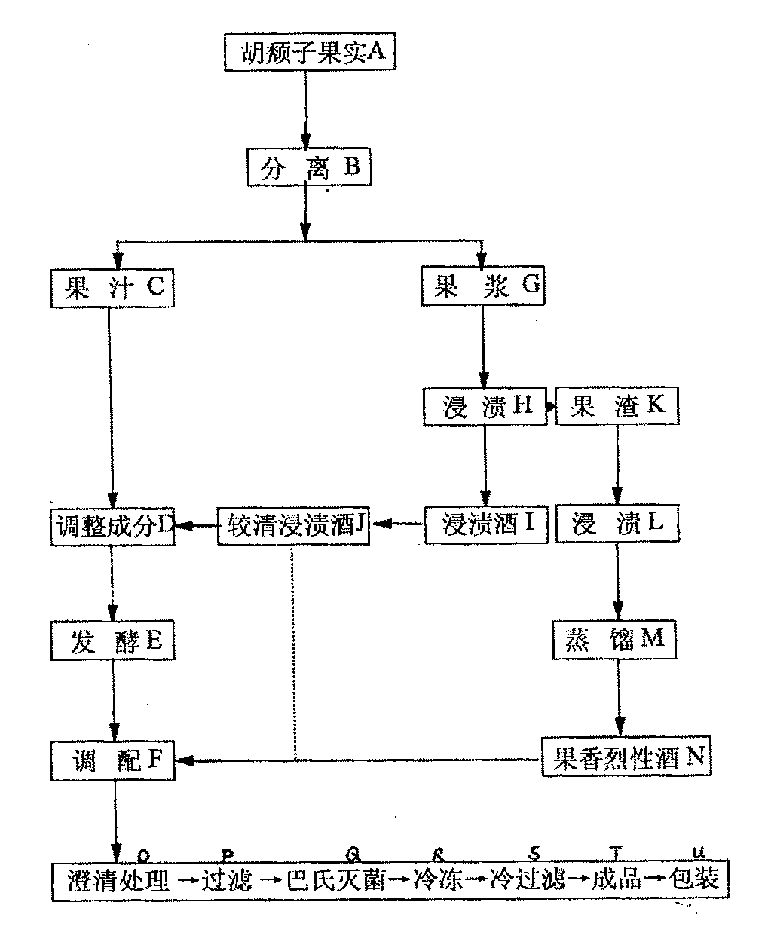

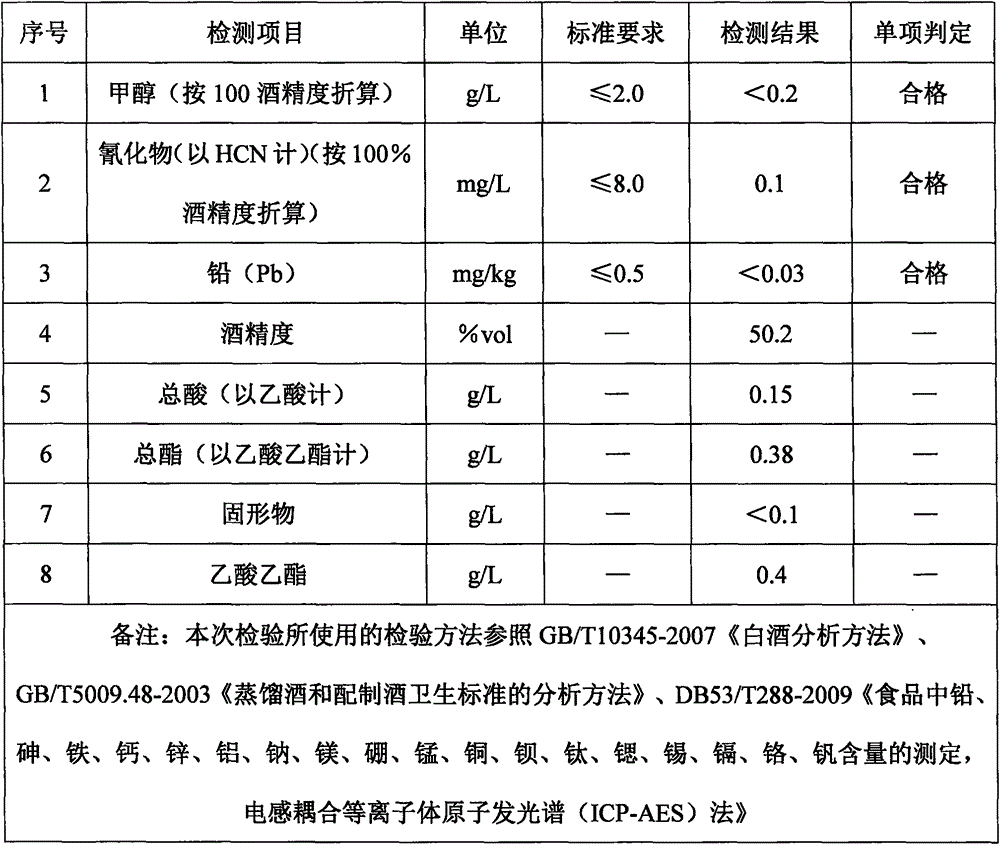

Thorny elaeagnus fruit wine

InactiveCN1369548AFruity and elegantAlcoholic and refreshingAlcoholic beverage preparationFruit wineAlcohol

A thorny elaeagnus fruit wine is prepared from the wild thorny elaeagnus fruit through fermenting its fruit juice to obtain fermented fruit wine, immersing the fruit pulp in alcohol to obtain immersed wine, distilling to obtain spirit, and proportionally mixing then together. Its advantages are rich nutrients and health-care function.

Owner:何先远

Production technology for brewing moringa oleifera Chinese spirits by fermentation distillation method

InactiveCN105969623ASimple processProgrammaticMicroorganism based processesAlcoholic beverage preparationYeastMicroorganism

The invention discloses a production technology for brewing moringa oleifera Chinese spirits by a fermentation distillation method. Fresh and complete roots, stems and peduncles of moringa trees are selected, cleaned and aired; the prepared moringa raw materials are cut into pieces, de-enzyming by microwaves is performed, and the pieces are crushed into particles; high-quality grain is selected and crushed into particles; transparent mountain spring water or underground water meeting standards is selected and boiled; yeast required by microbial fermentation is prepared; the raw materials are mixed in weight ratio, stirred uniformly and put into a fermentation tank or a fermentation vat to be fermented, one-time stirring is required every day in first five days, a semi-sealing state is kept, a plastic bag is added for sealing on the seventh day, one-time stirring is required every other day, then maturity detection is performed, fermented mature spirits materials are put into brewing equipment to be distilled, and moringa oleifera Chinese spirits are obtained. The production technology is simple, the sequential operation is realized, the brewing cost is low, not only the small-scale production but also large-scale industrialization automatic production is facilitated, and a feasible approach is created for developing clean energy.

Owner:云南恒健辣木发展有限公司

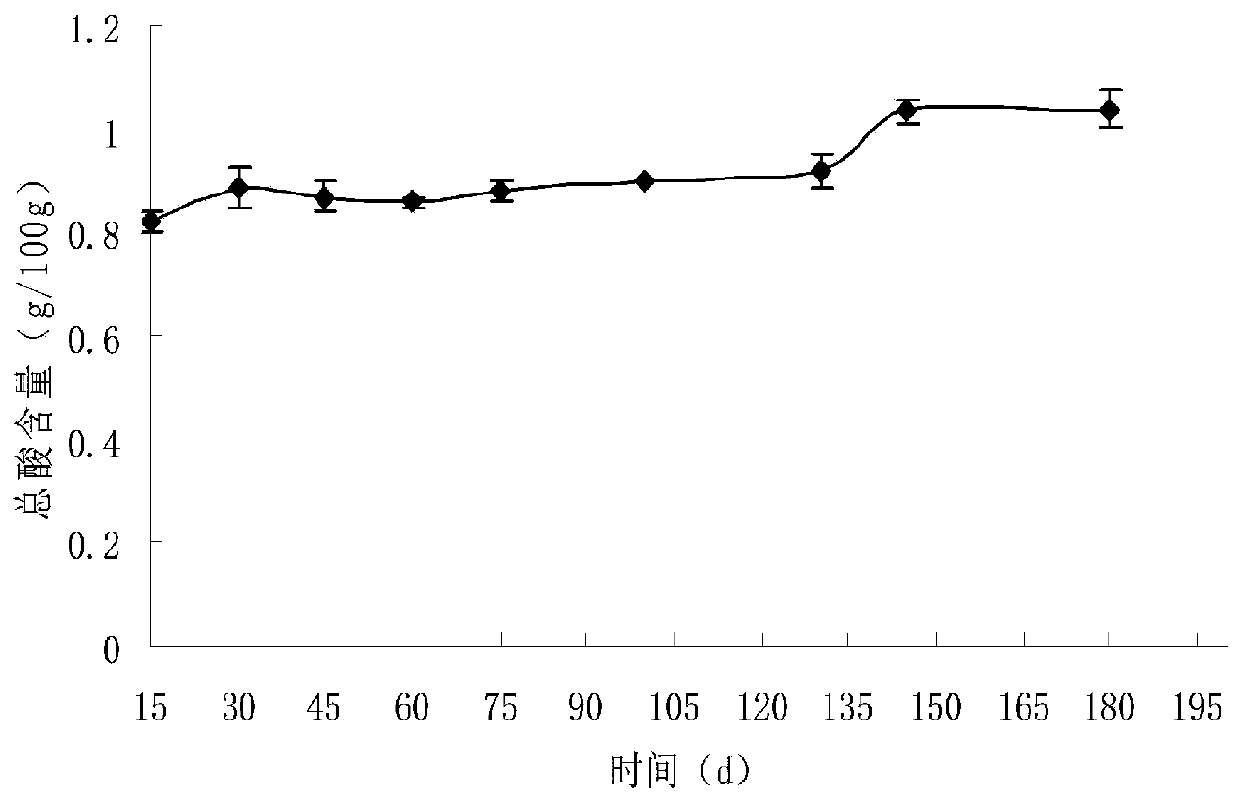

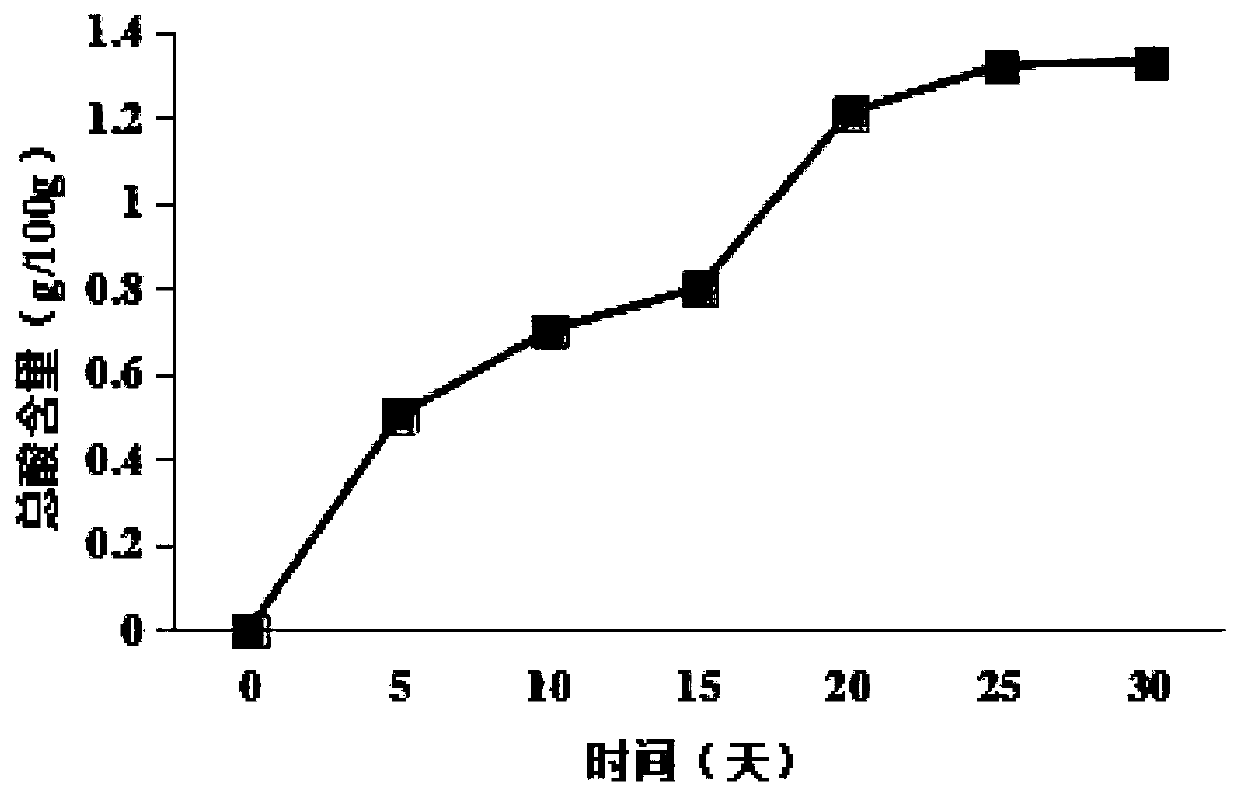

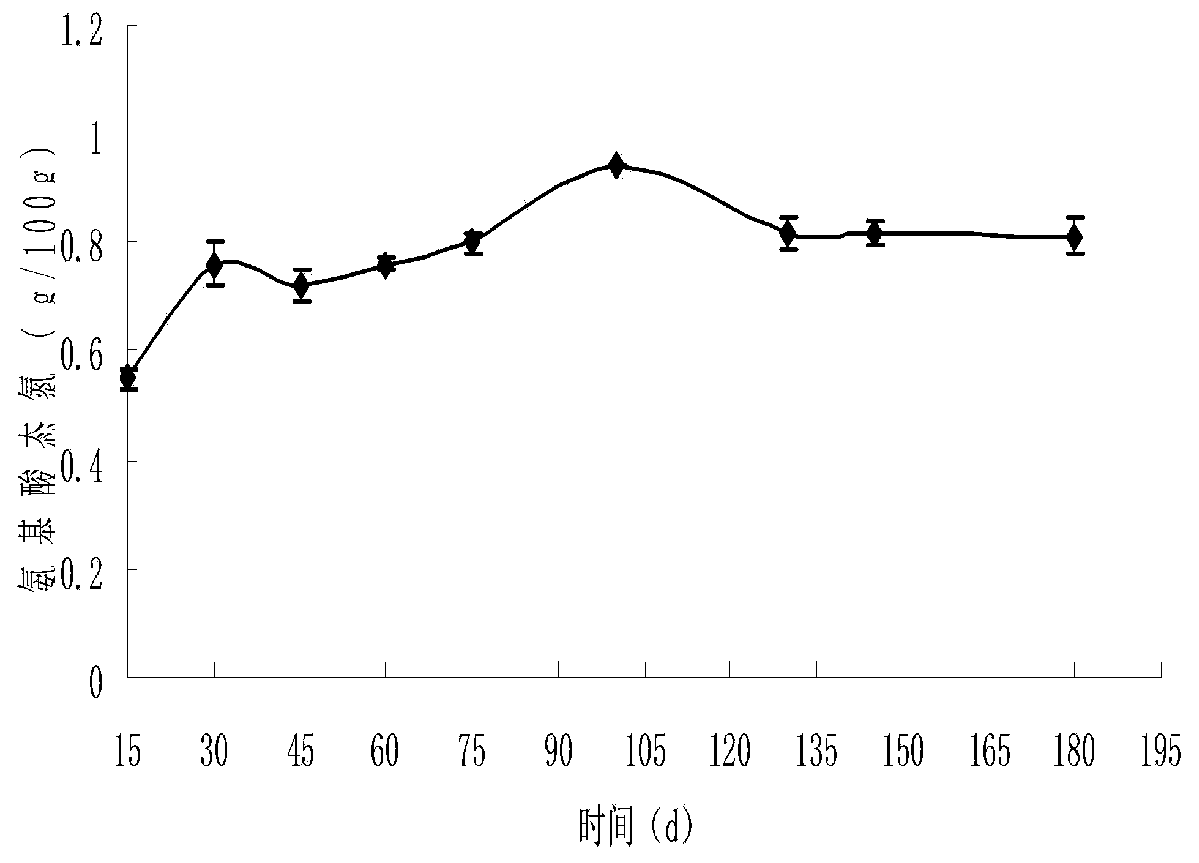

Making process of kochia scoparia and roselle tea vinegar

InactiveCN106190766AImprove qualityKeep active ingredientsAntipyreticAnalgesicsAdditive ingredientFiltration

The invention discloses a making process of kochia scoparia and roselle tea vinegar. The kochia scoparia and roselle tea vinegar is made by taking kochia scoparia and roselle as main raw materials trough the steps of raw material pretreatment, soaking, smashing, matrix processing, raw material blending, alcoholic fermentation, acetic fermentation, pressing filtration, mixing, homogenizing and aging, sterilization and filling and the like. Kochia scoparia and roselle widely available are utilized as main raw materials, making cost of tea vinegar can be lowered, nutritional ingredients in the tea vinegar can be enriched, and quality of the tea vinegar is improved; raw materials are subjected to steaming and microwave heating, so that inherent bitterness and moisture in raw materials are removed, active ingredients in raw materials can be fully kept, utilization efficiency of raw materials is increased, and the finished product tea vinegar has the healthcare efficacy of clearing heat and removing toxicity, inducing diuresis for treating strangurtia and the like.

Owner:芜湖市三山区绿色食品产业协会

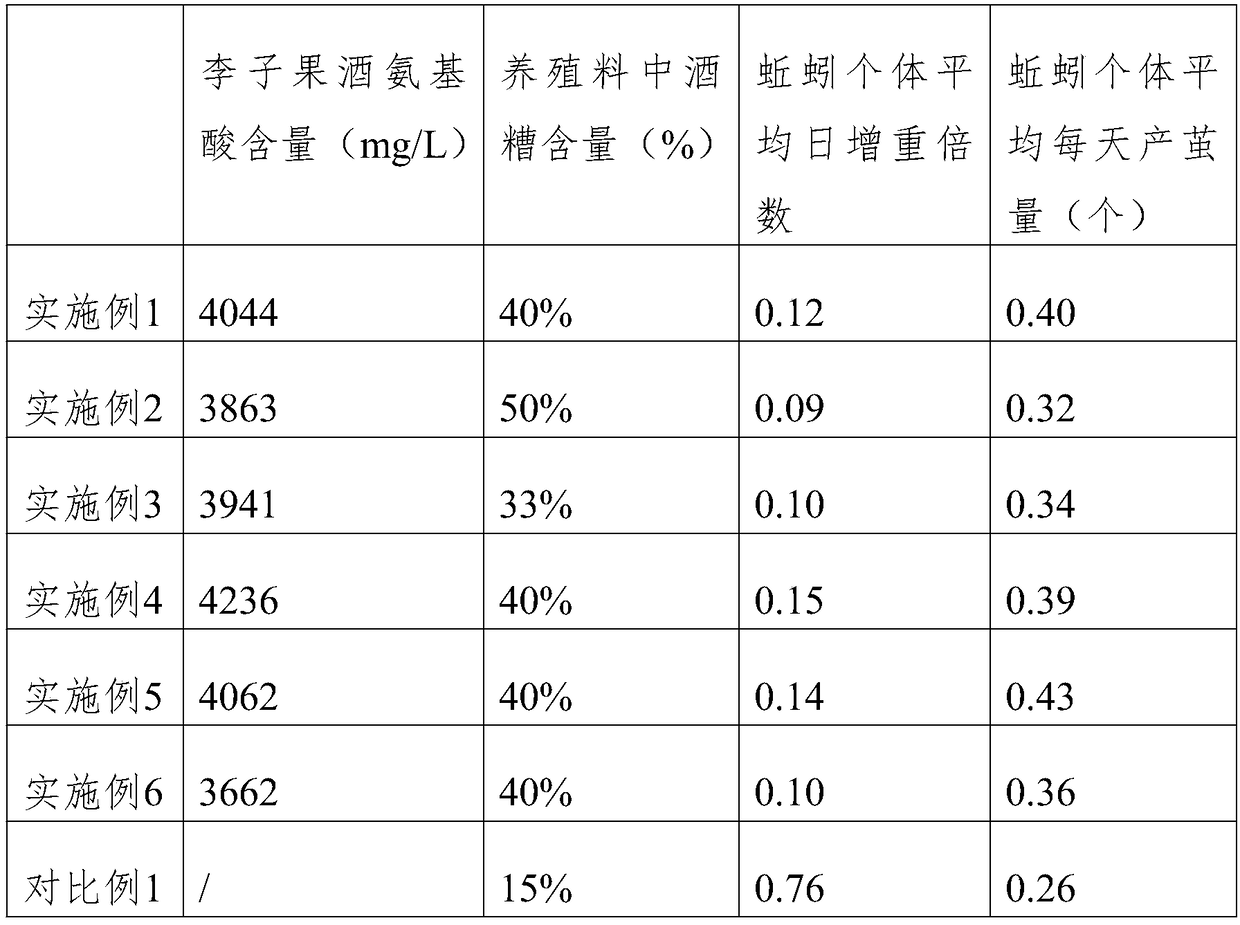

Method for preparing plum fruit wine and recycling fermentation waste residue

The invention belongs to the field of food processing, and relates to a method for preparing plum fruit wine and recycling fermentation waste residue. The fruit wine brewing process comprises the steps as follows: preparing fresh fruit, sorting, cleaning, crushing, disinfecting, squeezing juice, performing enzymatic hydrolysis, canning, fermenting, decanting, filtering, aging, mixing, sterilizing,filtering and obtaining a finished product; furthermore, the waste residue obtained by fermenting plums to prepare the fruit wine is a main component for preparing an earthworm breeding base materialused for breeding earthworms. The method disclosed by the invention overcomes the defects that the fruit wine produced with the traditional brewing method is long-lasting, time-consuming and easy tobe polluted, or defects caused by direct soaking. By adopting the method, a fruit wine drink which is simple in process, natural, green, healthy, rich in nutrition and mellow in flavor, and meets thedemands of widespread customers is obtained. Moreover, the fruit wine fermentation waste residue is taken as the main material for breeding the earthworms, which turns wastes into treasures, thereby avoiding the discharging of the fruit wine fermentation waste residue, reducing the waste treatment expense and fulfilling the purpose of recycling the wastes.

Owner:ZUNYI NORMAL COLLEGE

Seasoning wine

InactiveCN103396911AAvoid odorAffect qualityAlcoholic beverage preparationYeastManufacturing technology

The invention discloses seasoning wine, which belongs to rice wine and aims to provide seasoning wine with simple preparing technology and low brewing cost. The seasoning wine is prepared by brewing the following raw materials in parts by weight: 50 parts of sticky rice, 2-3 parts of yeast and 100-150 parts of water. A brewing method of the seasoning wine comprises the following steps of: soaking the sticky rice in warm water at the temperature of 30-35 DEG C for 24 hours after washing the sticky rice clean, fishing out the sticky rice, steaming, spreading for cooling, and cooling; uniformly mixing the cooled cooked sticky rice with the yeast and the water, and naturally fermenting for 30 days at a normal temperature; pressing and filtering the fermented sticky rice, and clarifying a filtrate to obtain the seasoning wine. The seasoning wine disclosed by the invention is soft and delicate in flavor, rich in fragrance, mild in alcoholic degree and full of nutriments, and has the advantages of simple manufacturing technology, low brewing cost and the like; the seasoning wine is rice wine prepared by brewing sticky rice used as a raw material.

Owner:杨凤群

Making technology of nectarine liquor

InactiveCN108165445AKeep the flavorIncrease the aroma of aging wineAlcoholic beverage preparationFlavorFermentation

The invention discloses a making technology of nectarine liquor, and belongs to the technical field of liquor making. The technology is simple in procedure and easy to popularize, nectarines do not need to be smashed or squeezed to prepare fruit pulp, exogenous yeast does not need to be added for fermentation, the original flavor of the nectarines is reserved, the nectarines are mixed with a grainfermentation material to be distilled, and not only is ageing liquor fragrance of the nectarine liquor improved, but also the making cost is lowered. The nectarine liquor has rich fruit fragrance andmellow mouthfeel.

Owner:泸西县顺创生物开发有限公司

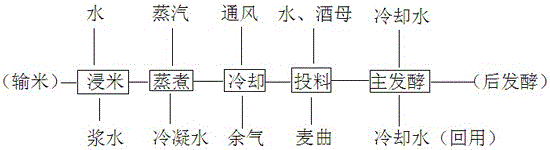

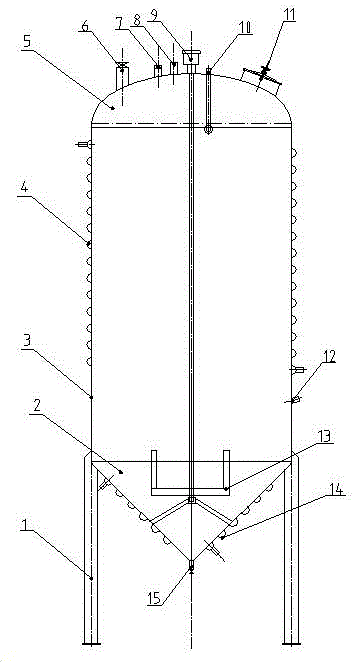

Environment-friendly brewing technology of rice wine

InactiveCN105886229AReduce cleaning and sterilizationSave cleaning and sterilizationAlcoholic beverage preparationExhaust valveYield (wine)

The invention relates to an environment-friendly brewing technology of rice wine. The technology includes the following steps that 1, raw material rice is soaked; 2, a starch solution is drained for 2 h or longer; 3, steam introduction is kept for more than 8 min till the rice is thoroughly steamed; 4, after heat preservation lasts for about 10 min, an exhaust valve is switched on, a ventilator is started, a vent valve is switched on, and the temperature of the steamed rice is decreased to 60 DEG C or lower; 5, formula water, yeast and koji are added, stirring is carried out, and the temperature of the mixture is controlled to be 25-30 DEG C; 6, the temperature rises and reaches 32-37 DEG C after 8 h of fermentation, stirring is carried out, the mash temperature is controlled, and main fermentation mash is obtained. According to the technology, the steps of wet rice conveying and steamed rice conveying are omitted, rice soaking equipment, rice steaming equipment and fermentation equipment are integrated by adopting micropressure rice steaming and multifunctional brewing equipment, the procedures are reduced, labor and steam are saved, cleaning and sterilization are thorough, the micropressure rice steaming and multifunctional brewing equipment is suitable for steaming various types of raw material rice and capable of reducing steaming loss, the wine yield is increased due to thorough steaming, automatic wine brewing production can be easily achieved, the brewing cost is lowered, and environment-friendly brewing of the rice wine is achieved.

Owner:沈红娟

Fruit vinegar brewed by using waste grape pomace

InactiveCN105385559ABright red colorStrong aromaMicroorganism based processesVinegar preparationVitis viniferaCellulase

The invention relates to an edible vinegar, in particular to a fruit vinegar brewed by using waste grape pomace. The fruit vinegar is prepared by the following steps of breaking the grape pomace to be 60-80 mesh particles to obtain grape pomace pulp; uniformly mixing the grape pomace pulp with skim milk according to the volume ratio of 1:0.2 and then inoculating the grape pulp with cellulase which accounts for 2 to 2.3 percent of the weight of the grape pomace pulp; performing shake culture on a rotary shaker with the temperature of 30 DEG C and the speed of 180r / min for 98 to 100 hours and then treating by using microwave with the power of 450 to 480W for 4 to 6 minutes; adding molasses which accounts for 20 to 22 percent of the weight of the grape pomace pulp, and inoculating the grape pulp with monascus which accounts for 0.2 to 0.5 percent of the weight of the grape pomace pulp; performing shake culture on a rotary shaker with the temperature of 28 DEG C and the speed of 200r / min for 30 to 40 hours and treating by using microwave with the power of 520 to 550W for 4 to 6 minutes; adding dried orange peel which accounts for 3 to 5 percent of the weight of the grape pomace pulp, sealing, storing at a ventilation place for three mouth or more, filtering and removing residues to obtain a final product.

Owner:全椒县荣昌葡萄种植专业合作社

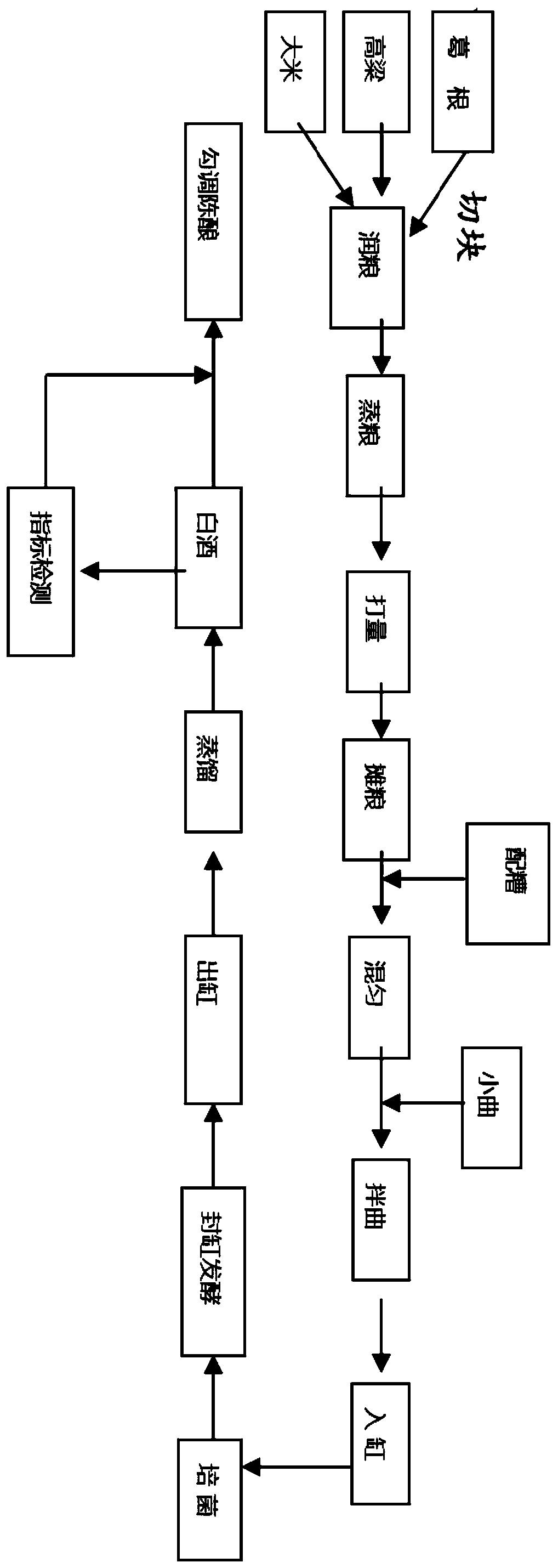

Brewing method of health-preserving Huoshan dendrobium officinale wine

PendingCN113004996AThe wine is clear and transparentThe entrance is sweetAlcoholic beverage preparationBiotechnologyAMERICAN GINSENG ROOT

The invention belongs to the technical field of dendrobium wine brewing, and particularly relates to a brewing method of health-preserving Huoshan dendrobium officinale wine. The problems that in the prior art, the utilization rate of effective components of dendrobium huoshanense is low, and nutrition waste is easily caused; the dendrobium huoshanense wine brewing cost is high, the wine yield is low, and the wine flavor is single are solved. The brewing method comprises the following steps: crushing Huoshan dendrobium officinale, stirring and mixing the crushed Huoshan dendrobium officinale with polished round-grained rice and glutinous rice, adding water for soaking, then boiling the raw materials, preserving heat, and cooling the mixture to room temperature; sequentially adding distiller's yeast and yeast while grinding, uniformly mixing the components, and sealing and fermenting the mixture; mixing and crushing American ginseng and dried longan, adding, uniformly stirring and mixing the components, heating the mixture in a water bath until boiling, sealing the liquid while hot, cooling and storing the liquid; and unsealing and filtering the liquid, and carrying out pasteurization. The Huoshan dendrobium officinale wine prepared by the invention has the effects of regulating yin and yang, maintaining beauty and keeping young, soothing the nerves and strengthening the brain, regulating internal secretion of a human body, enhancing the immunity of the human body and the like.

Owner:安徽霍山鹏泽生物科技有限公司

Flavor barley wine and brewing method thereof

The invention relates to a flavor barley wine and a brewing method thereof. The brewing method comprises the following steps: selecting material, grinding, moistening material, stirring material, cooking, spreading and drying in the air, adding distiller's yeast to stir, moistening material again, fermenting, baking the wine, storing, blending and filtering. The invention adopts the technology combining solid natural fermentation with cooling and baking to brew the flavor barley wine, thus the liquor yield is high, the wine quality is good and nearly has no impurity; and the bitterness of the wine can be reduced by controlling the time of secondary material-moistening and the mouthfeel of the wine is good. The brewed flavor barley wine comprises the following components: 72vol.% of alcohol and 90-110g / 100mL of acid. Therefore, the demand of people for drinking the high-degree flavor barley wine can be satisfied. The brewing method of the invention can be used in Tibet, thus the brewing cost is reduced and the economic development of Tibet can be promoted.

Owner:葛庆有

Grape wine and preparation method thereof

InactiveCN107574056ARich tasteRich flavorAntinoxious agentsWine preparationSalvia miltiorrhizaDisease

The invention relates to the technical field of alcoholic beverage preparation and particularly relates to grape wine and a preparation method thereof. The grape wine comprises the following raw materials: fresh grapes, red dates, salvia miltiorrhiza, dendrobium officinale, angelica sinensis, barbary wolfberry fruits, honey, orange juice, 7 parts of yeast, saccharose and pseudo-ginseng. The grapewine provided by the invention has abundant taste, thick flavor, various nutrition values, anti-fatigue effect, capability of enhancing human immunity and disease resistance, certain healthcare function, capability of improving the taste of the grape wine and suitability for taste of Chinese people; the wine quality is high; the preparation method is simple and feasible; the brewing cost is low; the production period is short; the grape wine has wide market prospect.

Owner:灵川县龙达种植专业合作社

Kudzuvine root distilled liquor and preparation method thereof

PendingCN111269774ACoordination contentImprove bulkMicroorganism based processesAlcoholic beverage preparationBiotechnologyYield (wine)

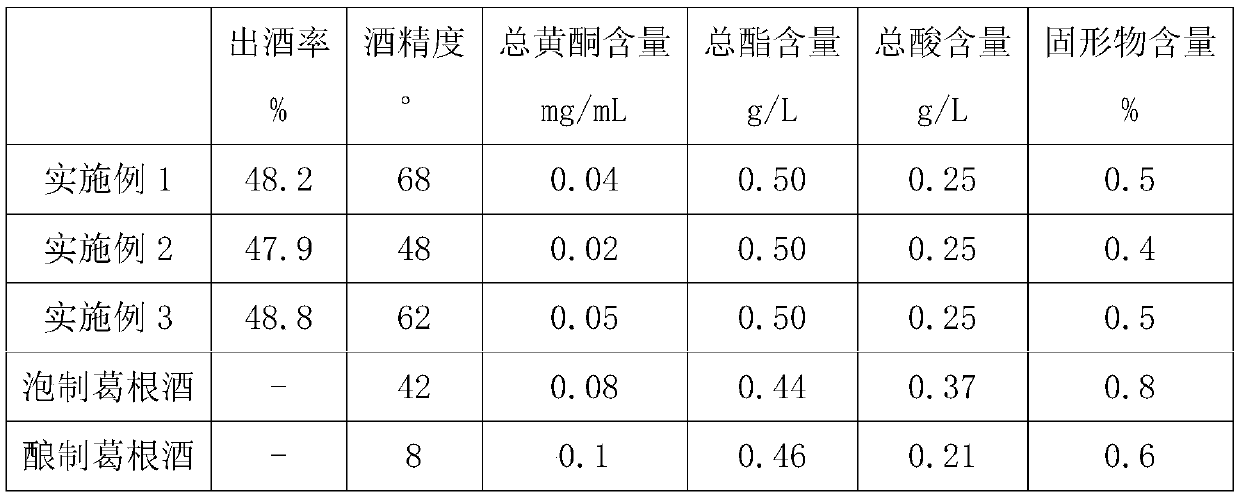

The invention discloses kudzuvine root distilled liquor and a preparation method thereof. The preparation method comprises the following steps: cooking kudzuvine root, sorghum and rice, spreading andairing to room temperature, adding blended grains, uniformly mixing, adding multi-trace kudzuvine root Xiaoqu accounting for 2-3wt% of the total mass of kudzuvine root, sorghum, rice and blended grains, putting into a jar, culturing for 2-3d, sealing the jar, fermenting for 7-10d, taking out of the jar, distilling and blending. The kudzuvine root and the sorghum are uniformly mixed according to acertain proportion; the brewed kudzu vine root distilled health-care wine is high in wine yield, full in raw material utilization, full in Xiaoqu wine body, relatively high in alcoholic strength, refreshing and harmonious in taste, soft, pure and sweet, has the unique faint scent of sorghum and kudzuvine root, is relatively high in active substance content, and has a certain health-care effect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Brewing method of alcohol-free beer

The invention relates to a brewing method of alcohol-free beer. The brewing method comprises the following steps of a step (I), preparation of raw materials; a step (II), preparation of wort; a step (III), treatment of the wort; a step (IV), low-temperature anaerobic fermentation. The alcohol-free beer brewed by adopting the brewing method provided by the invention has the overall taste style characteristic of beer, is clear and transparent in wine body, is golden in color and luster, is pure white, fine, smooth and abundant in foam, has a distinct and peculiar fragrance of malt and the beer, and is refreshing and pure in mouth feel, and also has the technical advantages that the brewing cost is slow, the fermentation period is short, the storage life of a product is long, and the equipment investment is low.

Owner:西安百家宝酿造科技有限公司

Method for preparing soybean paste from vinegar residues

InactiveCN111264776ALower brewing costsThe solution to natural digestionFood ingredient as pH modification agentBiotechnologyAspergillus oryzae

The invention relates to a method for preparing soybean paste from vinegar residues, comprising the following steps: (1) taking soybeans, removing impurities, cleaning and soaking; (2) draining the soybeans, performing steaming for 30min, and performing steaming with vinegar residues for 15-20min; adjusting the pH value of the steamed vinegar residues to 5.5-7; immediately and uniformly mixing thesteamed soybeans with the steamed vinegar residues, and reducing the stirring temperature to 45-40 DEG C; (3) inoculating aspergillus oryzae koji essence, uniformly stirring and mixing, and carryingout stacking culture; (4) carrying out first koji turning, carrying out second koji turning, and continuously carrying out tiled culture at 30 DEG C; (5) culturing for 10-13 hours, and mixing with brine; and (6) performing heat preservation and fermentation at 45-55 DEG C for 15-30 days to obtain the soybean paste. According to the method, by controlling the proportion of the vinegar residues, theproduction quality of the soybean paste is controllable, the brewing cost of the soybean paste is reduced, the problem of natural digestion of the vinegar residues in the seasoning fermentation industry is solved, the vinegar residues are taken as vinegar to be used for the paste, and zero emission of vinegar production is truly achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Pure natural hand brewing method of brown rice wine

InactiveCN106957772ABrewing method is simpleLower brewing costsAlcoholic beverage preparationHorticultureYeast

The invention discloses a pure natural hand brewing method of brown rice wine. The pure natural hand brewing method comprises the following steps: (1) cleaning brown rice and soaking for 6-8 hours with a proper amount of purified water; (2) uniformly stirring the soaked brown rice and the purified water and thoroughly steaming with big fire in a manner of water separation; (3) spreading, smashing and cooling the streamed brown rice till a hand feels the temperature tepid; (4) adding smashed distiller's yeasts, uniformly mixing and sealing with a jar for preliminary fermentation; (5) after preliminary fermentation for 24 hours, digging a dimple with a diameter and a depth of 30-50 mm in the center of the upper end surface of brewed brown rice wine and removing a wrappage of the jar for continuous deep fermentation; (6) after deep fermentation for about half a month, pressing and filtering the brewed brown rice wine, wherein liquid obtained by filtering is the brown rice wine, and a filtrate obtained by filtering is brown rice wine lees. The pure natural hand brewing method disclosed by the invention is simple and easy to operate, and is used for helping the vast numbers of ordinary people to brew the healthy and low-cost brown rice wine at home.

Owner:李晓旭

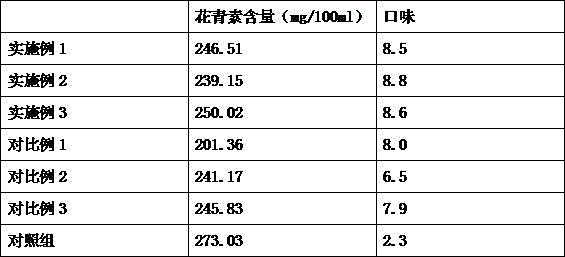

Nutrition fruit wine

InactiveCN106675905AIncrease profitGood health effectDigestive systemMicroorganism based processesHuman bodyYeast

The invention relates to a nutrition fruit wine. The nutrition fruit wine is made from, by weight, 80-100 parts of grapes, 20-30 parts of black currants, 8-10 parts of purple corn grains, 8-10 parts of purple sweet potatoes, 3-5 parts of lyceum ruthenium, 10-15 parts of high fructose syrup, 3-5 parts of honey, 1-2 parts of compound enzyme, 1-2 parts of Angel active dry yeast, 5-8 parts of fresh ginger extract, 2-3 parts of peppermint extract and 20-30 parts of distilled water. The raw materials rich in anthocyanin are adopted, various nutrient elements required in the human body are provided, the fruit wine is higher in health care effect, the raw materials are rich in types of materials, and the brewed fruit wine is richer in taste; as is shown in the experiment, the fruit wine is high in anthocyanin, and beneficial to health for long-term drinking.

Owner:蒋金刚

Method for preparing fermented soya beans from soy sauce residues

InactiveCN111264775ARealize zero emission in productionThe solution to natural digestionFood scienceBiotechnologyAspergillus oryzae

The invention relates to a method for preparing fermented soya beans by using soy sauce residues. The method comprises the following steps: (1) removing impurities from soybeans, cleaning and soaking;(2) draining the soybeans, performing steaming for 30min, steaming bran and soy sauce residues for 15-20min, and immediately and uniformly mixing the steamed soybeans with the steamed bran and soy sauce residues; (3) inoculating aspergillus oryzae koji essence accounting for 0.3-0.5% of the total weight of the raw materials, uniformly stirring and mixing, and carrying out stacking culture; (4) carrying out first koji turning, carrying out second koji turning, and continuously carrying out tiled culture at 30 DEG C; (5) collecting koji when the koji material is faint yellow after culturing for10-13 hours; (6) mixing with brine; and (7) performing heat preservation and fermentation at 45-55 DEG C for 10 days, and performing heat preservation and fermentation at 30-35 DEG C for 15-30 days so as to obtain the fermented soya beans. According to the method, by controlling the proportion of the soy sauce residues, the production quality of the fermented soya beans is controllable, the brewing cost of the fermented soya beans is reduced, the problem of natural digestion of the soy sauce residues in the seasoning fermentation industry is solved, the soy sauce residues are used for soybeans, and zero emission of soy sauce production is truly realized.

Owner:TIANJIN UNIV OF SCI & TECH

Cooking wine

The invention discloses cooking wine, belongs to rice wine, and aims to provide cooking wine which is simple in technology and low in brewing cost. The cooking wine is prepared through brewing the following raw materials in parts by weight: 50 parts of polished glutinous rice, 2-3 parts of distiller's yeast and 100-150 parts of water. A brewing method of the cooking wine comprises the following steps of thoroughly cleaning the polished glutinous rice, soaking the cleaned polished glutinous rice in warm water of 30-35 DEG C for 24 hours, fishing out the soaked polished glutinous rice, steamingthe fished-out polished glutinous rice to obtain cooked polished glutinous rice, spreading the cooked polished glutinous rice for cooling, and performing cooling; uniformly mixing the cooled cooked polished glutinous rice with the distiller's yeast and the water, and performing natural fermentation at normal temperature for 30 days; and squeezing the fermented polished glutinous rice, performing filtration, and clarifying filtrate so as to obtain the cooking wine. The cooking wine disclosed by the invention is soft, fine and smooth in wine taste, rich in fragrance, mild in alcoholic strength and rich in nutrients, has the advantages of being simple in making technology, low in brewing cost and the like, and is rice wine prepared through brewing the polished glutinous rice as a raw material.

Owner:李庆山

Cooking wine

InactiveCN109423389AAvoid odorAffect qualityAlcoholic beverage preparationWarm waterRoom temperature

The invention discloses cooking wine which belongs to rice wine, and aims at providing the cooking wine with simple process and low brewage cost. The cooking wine is brewed from the following raw materials, by weight: 50 parts of glutinous rice, 2-3 parts of distiller's yeast, and 100-150 parts of water. A brewage method has the following steps: washing the glutinous rice, soaking the glutinous rice in warm water at 30-35 DEG C for 24 hours, and performing removing, steaming, spreading and cooling; uniformly mixing the cooled cooked glutinous rice and the distiller's yeast and water, and naturally fermenting the mixture at room temperature for 30 days; and pressing and filtering the fermented glutinous rice so as to obtain the cooking wine after the filtrate is clarified. The cooking wineof the invention is soft and delicate in taste, strong in aroma, mild in wine property and rich in nutrition, has the advantages of simple making process, low brewage cost and the like, and is the rice wine brewed by using the glutinous rice as a raw material.

Owner:QINGDAO SHENGXIANGUAN E COMMERCE CO LTD

Fresh corn, velvet antler and flavone containing liquor

InactiveCN106497725ATo completely removeStable and miscibleAlcoholic beverage preparationShrimpPyrola

The invention discloses fresh corn, velvet antler and flavone containing liquor. The fresh corn, velvet antler and flavone containing liquor comprises the following raw materials in parts by weight: 140 to 160 parts of rice, 75 to 95 parts of fresh corn, 5 to 8 parts of sea shrimp powder, 4 to 6 parts of pyrola, 10 to 12 parts of pandan leaf juice, 13 to 15 parts of cotton seed hulls, 25 to 27 parts of velvet antler, 1 to 2 parts of ammonium sulfate, 36 to 40 parts of Pinus tabuliformis var. mukdensis needles, an appropriate amount of an ethanol solution of which the concentration is 50% and an appropriate amount of water; the liquor disclosed by the invention uses the fresh corn to replace a part of rice raw materials to carry out fermentation, so that the brewing cost of the liquor is reduced, and furthermore, a unique fresh scent of the fresh corn can be brought about for the liquor to increase the liquor taste and meet taste demands of some consumers.

Owner:ANHUI TIANXIAFU JIUYE

A kind of production method of citrus sparkling wine

ActiveCN104789414BGuaranteed stabilityImprove stabilityAlcoholic beverage preparationFruit winePreservative

Owner:四川华橙酒业有限公司

Method for brewing cooking wine by using brewer's grains

InactiveCN109418901AHigh alcohol contentMake full use of resourcesFood scienceAlcohol contentWarm water

The present invention discloses a method for brewing cooking wine by using brewer's grains. The method comprises the following steps: brewer's grains are heated and steamed to 28 DEG C-30 DEG C, yellow wine Chinese yeast is added, the materials are fully stirred to form mixed distiller's grains, fermentation holes are arranged in the middle parts of the mixed distiller's grains, heat preservationis conducted at a temperature of 28 DEG C-30 DEG C for 3 days, yellow wine is formed in the fermentation holes, then warm water at 28 DEG C-30 DEG C is added to the mixed distiller's grains, fermentation is conducted, stirring is conducted once every 9 hours and the fermentation is stopped after 7-8 days; and then squeezing, cooking, filtering, sealed storing and sterilizing are conducted to obtain the cooking wine. The method of the invention is simple in brewing process, low in brewing cost, and easy to popularize. The method uses the brewer's grains to brew the cooking wine, and is rich inraw material sources, less in investment, convenient to operate and low in production cost. On the one hand, the brewer's grains are used to replace polished round-grained rice and on the other hand,proteins in the brewer's grains are decomposed, nutrients in the cooking wine are increased, the alcohol content of the cooking wine is increased, at the same time, resources of the brewer's grains are fully utilized to increase the use value of the brewer's grains.

Owner:QINGDAO SHENGXIANGUAN E COMMERCE CO LTD

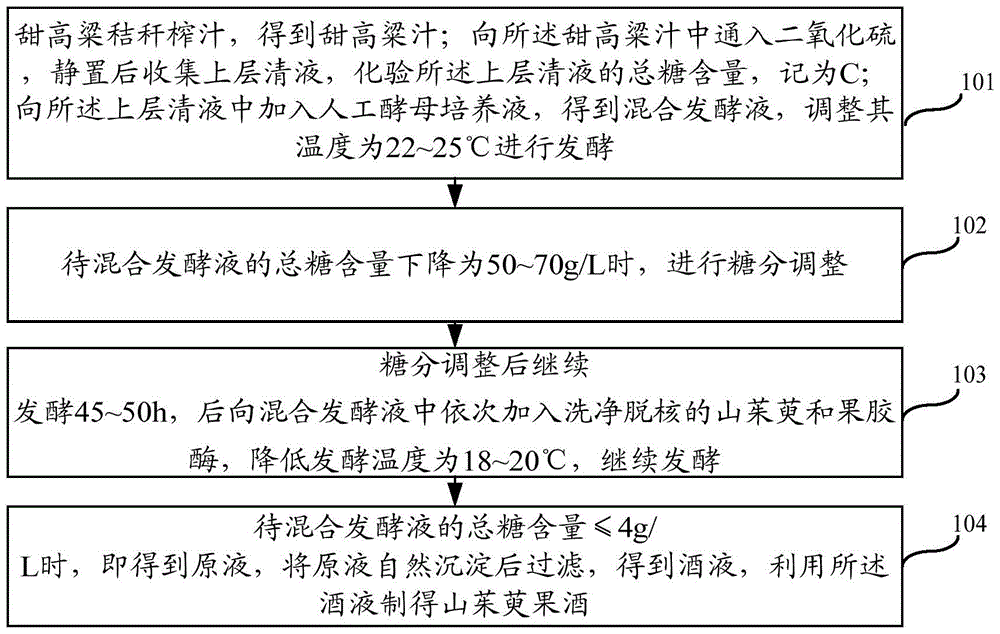

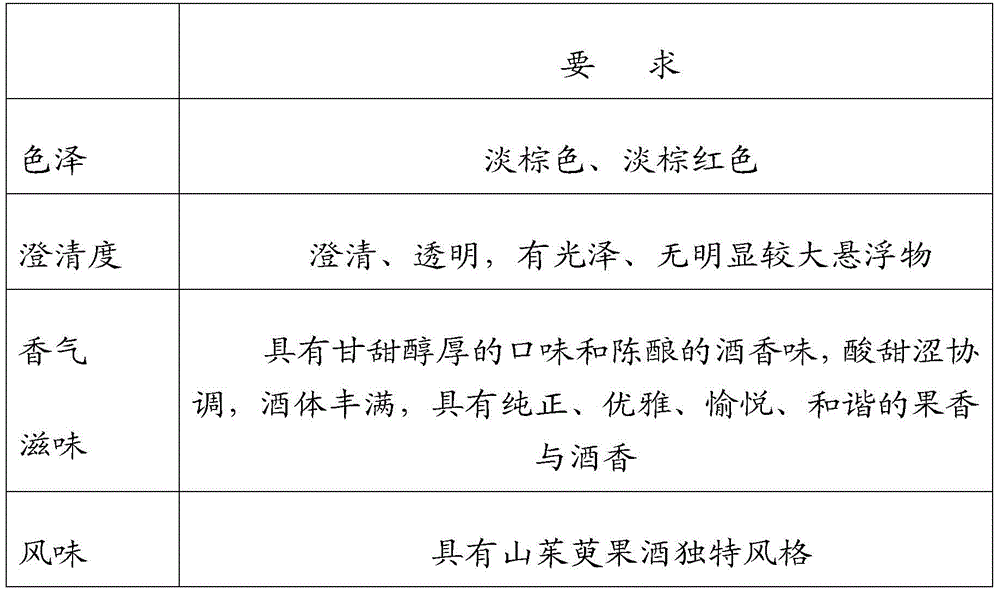

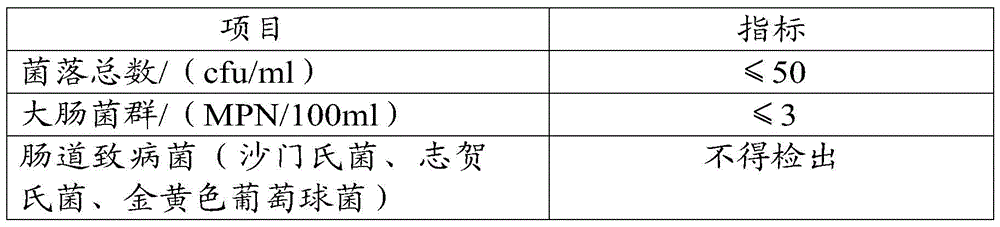

A kind of preparation method of dogwood fruit wine

ActiveCN104673590BShorten the growth cycleEasy to manageAlcoholic beverage preparationFruit wineCornus officinalis

The invention provides a method for preparing dogwood fruit wine. Sorghum bicolor straw juice and dogwood are taken as raw materials, and the total sugar content of the sorghum bicolor straw juice is up to 16-18%, so that the intrinsic fragrance of dogwood is not affected when the sorghum bicolor straw juice is adopted to ferment dogwood to brew wine, and moreover the fullness of the wine can be improved; meanwhile as sorghum bicolor is short in growth period, easy to manage and high in yield, the brewing cost of the dogwood fruit wine is greatly lowered. According to the method provided by the invention, the sorghum bicolor straw juice is firstly fermented, dogwood is subsequently fed, and the fermentation temperature is reduced in time for fermentation, so that the fruit fragrance loss of dogwood can be reduced, the bitter and astringent taste of finished wine can be reduced, the beneficial components of dogwood can be maintained to the maximum extent, and the prepared dogwood wine is rich and fine, fresh and elegant in fruit fragrance and soft in wine fragrance.

Owner:河南圆梦生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com