Production technology for brewing moringa oleifera Chinese spirits by fermentation distillation method

A production process and distillation technology, applied in the field of brewing, can solve the problems of competition for grain or land with grain, industrial application restrictions, high raw material cost, etc., and achieve the effects of low brewing cost, standardized operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

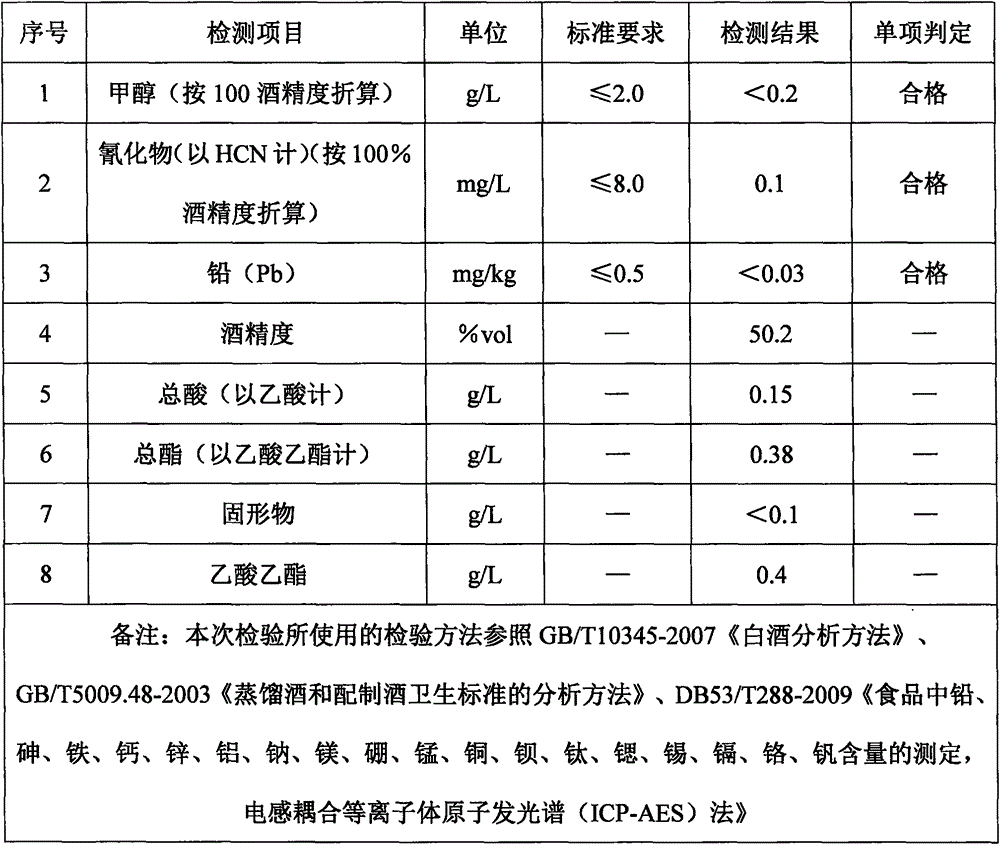

Image

Examples

Embodiment

[0028] The production process steps of brewing Moringa liquor by fermentation and distillation are as follows:

[0029] (1) select fresh and intact root, stem, stem of Moringa oleifera, wash and dry, and set aside;

[0030] (2) Preparation of raw material A: Cut the prepared Moringa oleifera raw material into 1mm slices with a traditional Chinese medicine slicer, use a microwave deenzyming machine at 90° C. for 10 minutes, and then use a traditional Chinese medicine crusher to crush it into 10-mesh granules for use;

[0031] Microwave refers to an electromagnetic wave with a wavelength in the range of 1-100cm (frequency 300MHz-300KMHz). Microwave processing time is short, the operation is simple, and the saccharification effect is obvious. Microwave can change the supramolecular structure of plant cellulose raw materials and make the cellulose crystallization area Change in size; able to partially degrade lignin and hemicellulose, thereby increasing its accessibility and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com