Environment-friendly brewing technology of rice wine

A green and rice wine technology, applied in the field of green rice wine brewing technology, can solve the problems of many transportation links, high building floors, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 : dry rice wine

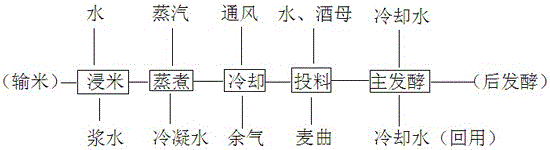

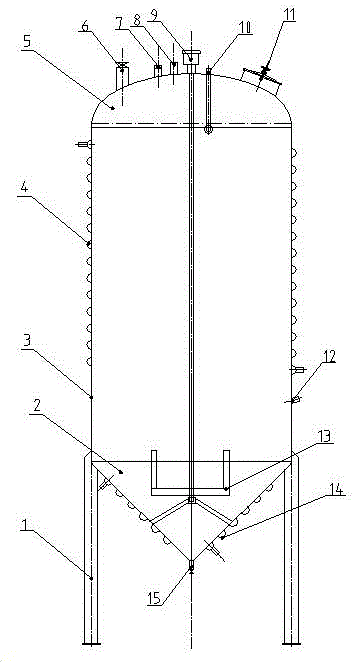

[0037] A kind of rice wine green brewing process and multi-functional brewing equipment provided by the present embodiment 1 comprise the following steps:

[0038] (1) Rice soaking (dry rice wine): 9,000 kg of raw rice is directly poured into a 30-cubic steel green multifunctional brewing equipment cleaned with clean water, and water is added. The ratio of rice to water is 1:0.8. Stir properly to fully mix the rice and water. , soaked for 8 hours;

[0039] (2) After step (1) is completed, open the bottom slurry discharge valve and discharge the slurry for 4 hours;

[0040] (3) After step (2) is completed, close the slurry water discharge valve, open the bottom steam valve, the steam pressure used is 0.10Mpa, close all other valves of the steel green multifunctional brewing equipment, and set the steam safety valve to be greater than the steam pressure of 0.11Mpa , after the steam pressure rises to the safety valve discharge, it still kee...

Embodiment 2

[0045] Example 2 : Semi-dry rice wine

[0046] In the green rice wine brewing process provided in Example 2, the step (1) is soaking rice (semi-dry type), except for "step (5) adding 13050 kg of formula water", the rest of the steps are the same as in Example 1, which will not be described here. repeat.

Embodiment 3

[0047] Example 3 : Semi-sweet rice wine

[0048] In the green rice wine brewing process provided in Example 3, the step (1) is soaking rice (semi-sweet type), except for "step (5) adding 15600 kg of dry rice wine as formula water", the rest of the steps are the same as in Example 1 , which will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com