Preparation device and preparation method for nano noble metal catalyst

A precious metal catalyst, a technology for preparing a device, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. It is safe and convenient to use, avoids the messy preparation environment, and facilitates centralized collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

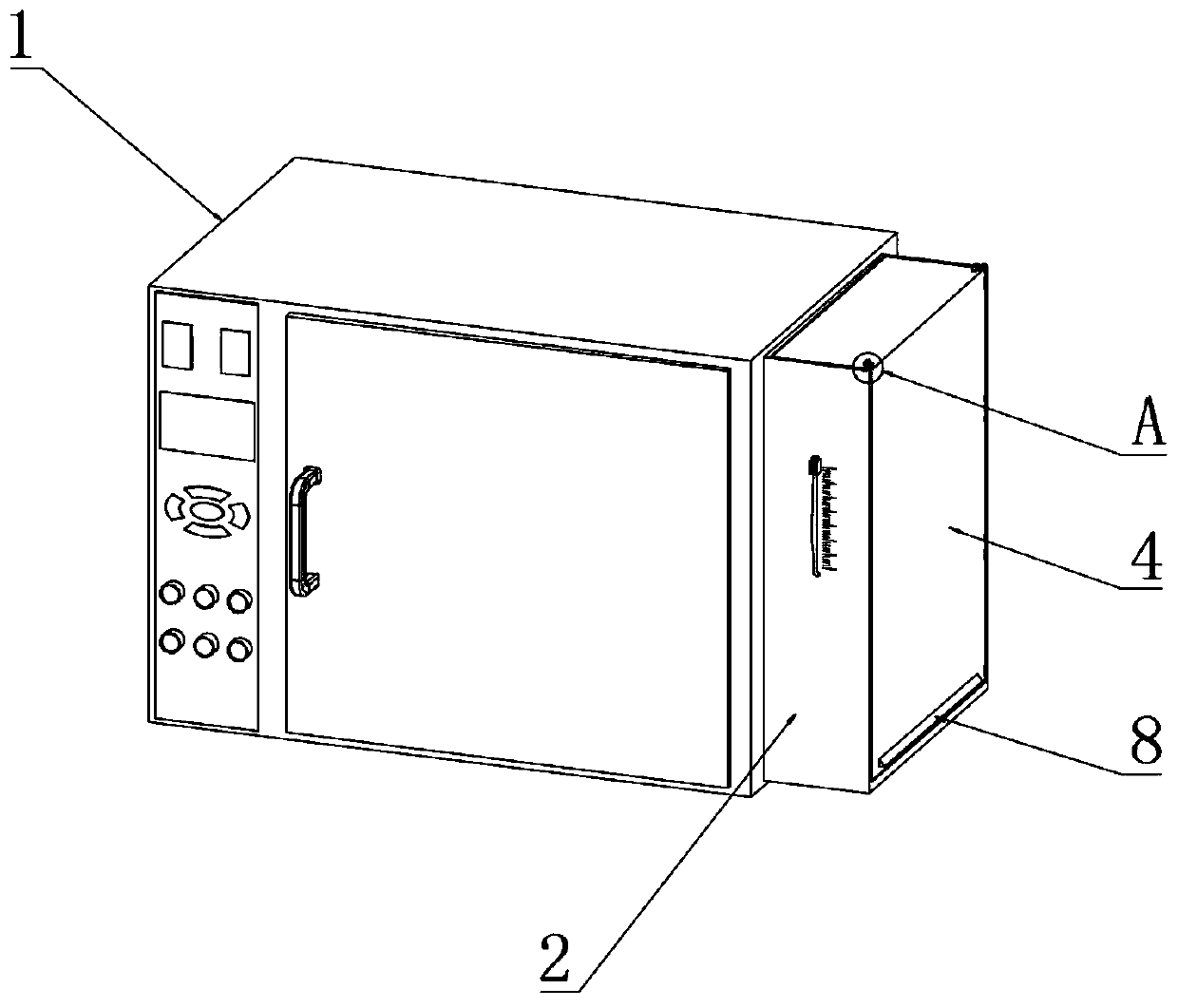

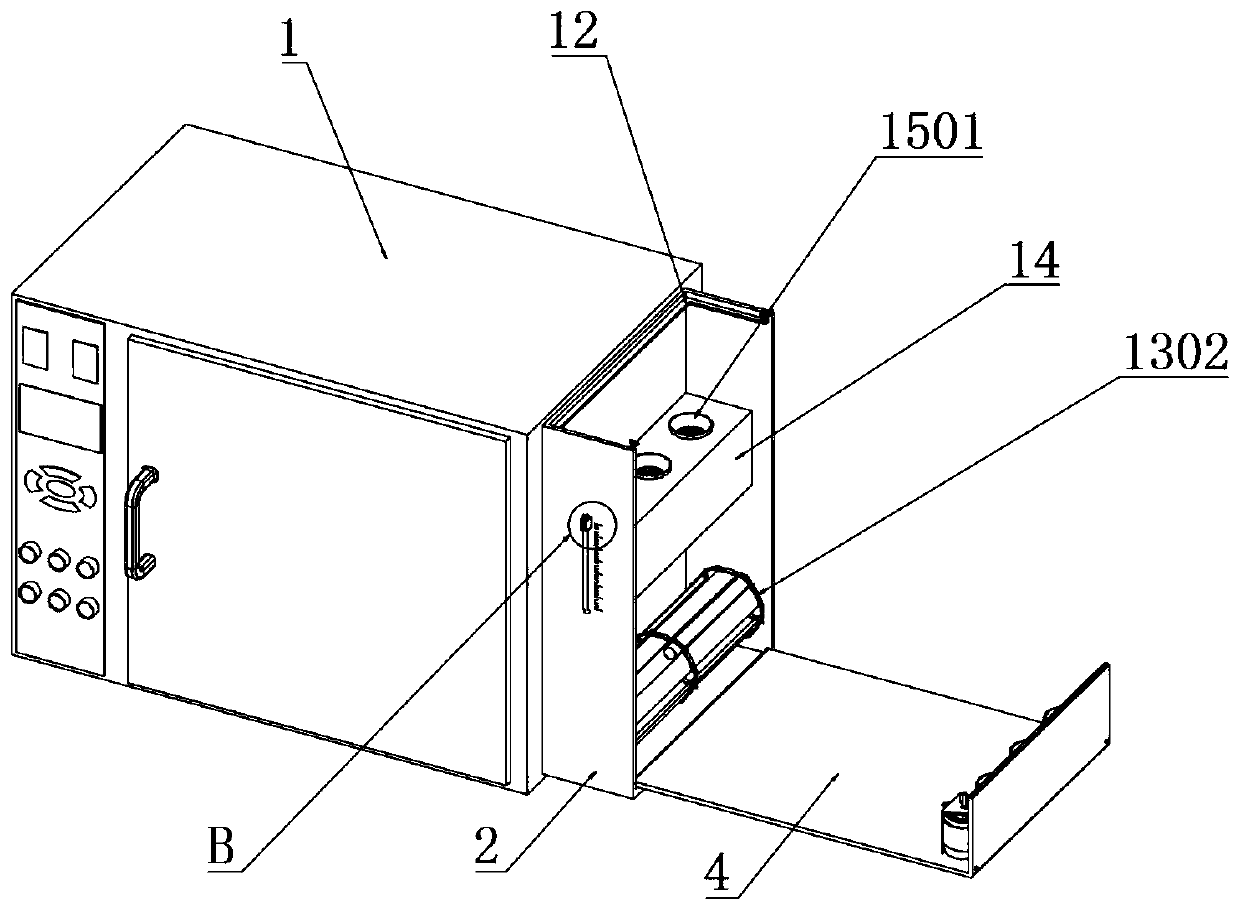

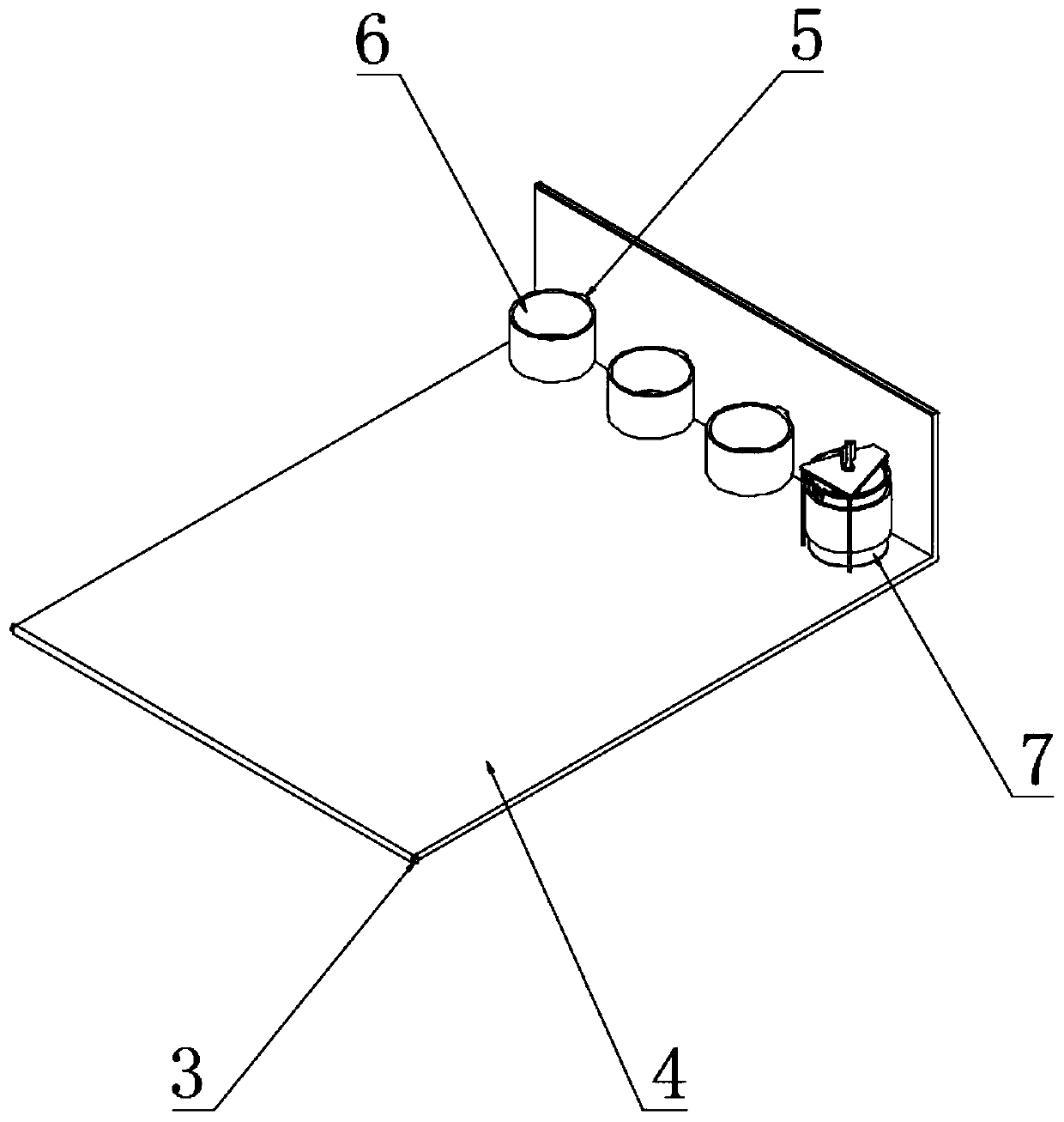

[0051] Embodiment 1: as Figure 1-11 As shown, the present invention provides a technical solution, a preparation device for nano-precious metal catalysts, including a low-temperature drying box 1, and the input end of the low-temperature drying box 1 is electrically connected to the output end of the mains to ensure low-temperature drying The normal power-on operation of the box 1, the storage box 2 is welded on the surface of the low-temperature drying box 1, the bottom of the storage box 2 is connected with the connecting shaft 3 through the rotation, the middle part of the connecting shaft 3 is sleeved with the working plate 4, and the shape of the working plate 4 It is L-shaped, and the L-shaped inner side of the working plate 4 is equidistantly welded with a connecting block 5, and the end face of the connecting block 5 is glued with a receiving cover 6, and a beaker 7 is installed inside the receiving cover 6.

[0052] The L-shaped outer side of the working plate 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com