Unmanned aerial vehicle facilitating shooting

An unmanned aerial vehicle, a convenient technology, applied in the field of unmanned aerial vehicles, can solve the problems of limited shooting angle, affecting the quality of shooting, large space occupied by support feet, etc., so as to increase the shooting angle, and facilitate shooting observation and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

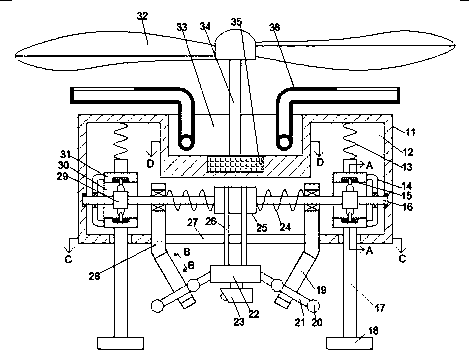

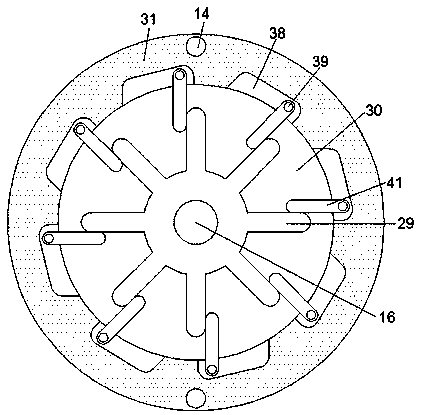

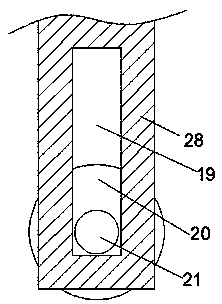

[0019] like Figure 1-Figure 6 As shown, a kind of unmanned aerial vehicle convenient for photographing of the present invention comprises fuselage 11, and described fuselage 11 is provided with transmission chamber 12, and described transmission chamber 12 lower end inner wall communicates and is provided with through hole 27, and described transmission chamber The inner wall of the bottom end of 12 is slidably connected with symmetrical foot rods 17 located at the left and right ends of the through hole 27, and a resistance spring 13 is connected between the upper end of the foot rod 17 and the top inner wall of the transmission chamber 12. The foot rod 17 The lower end is provided with soles 18 that are in contact with the ground, and four center-symmetric track arms 28 are fixedly connected in the through hole 27, and a camera lifting device is slidably connected in the track arms 28, and the transmission chamber 12 is rotationally connected There is a transmission shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com