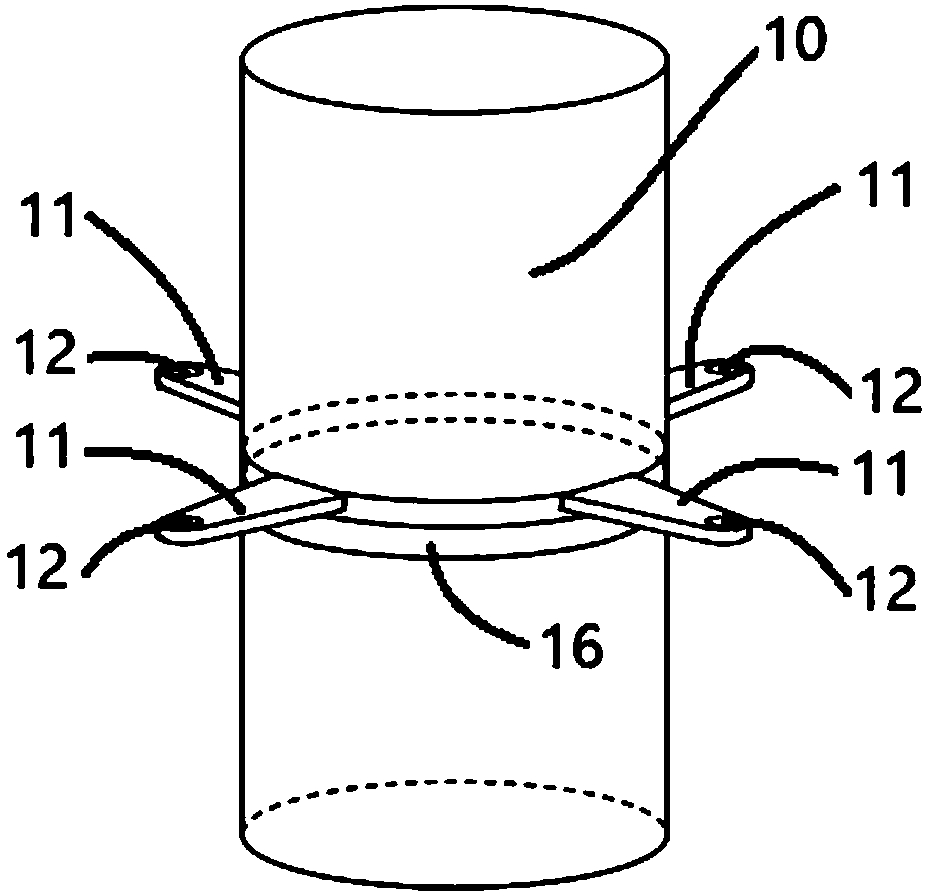

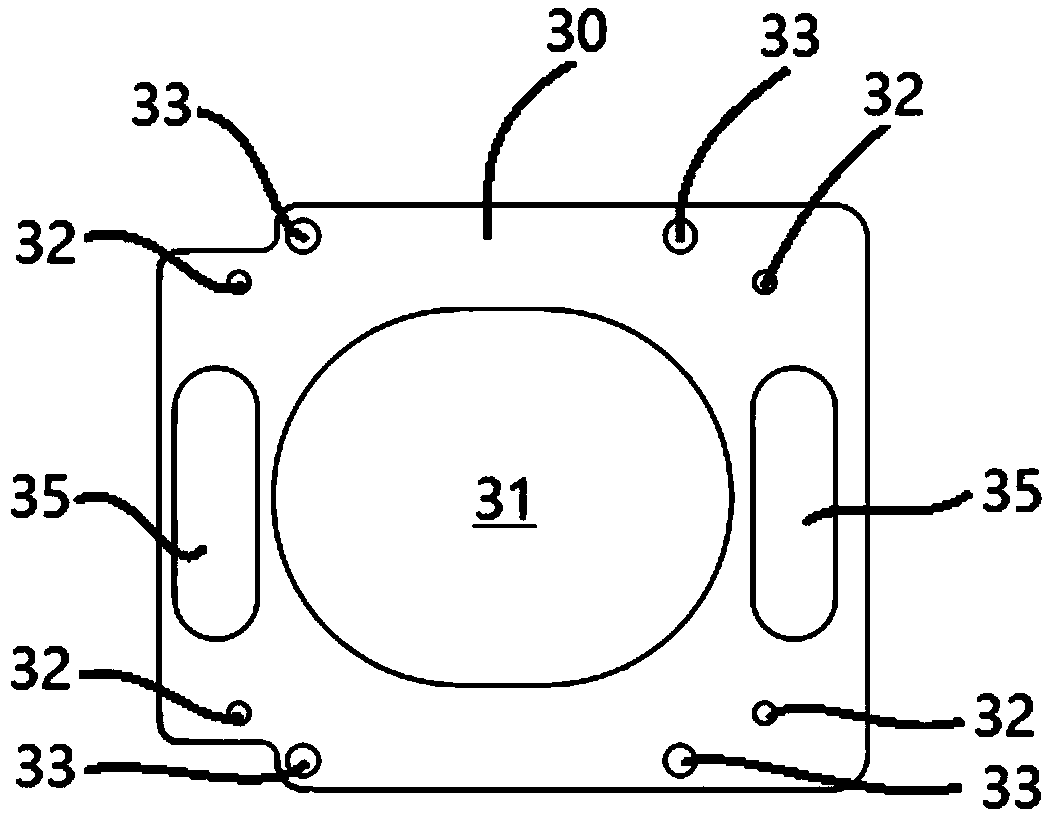

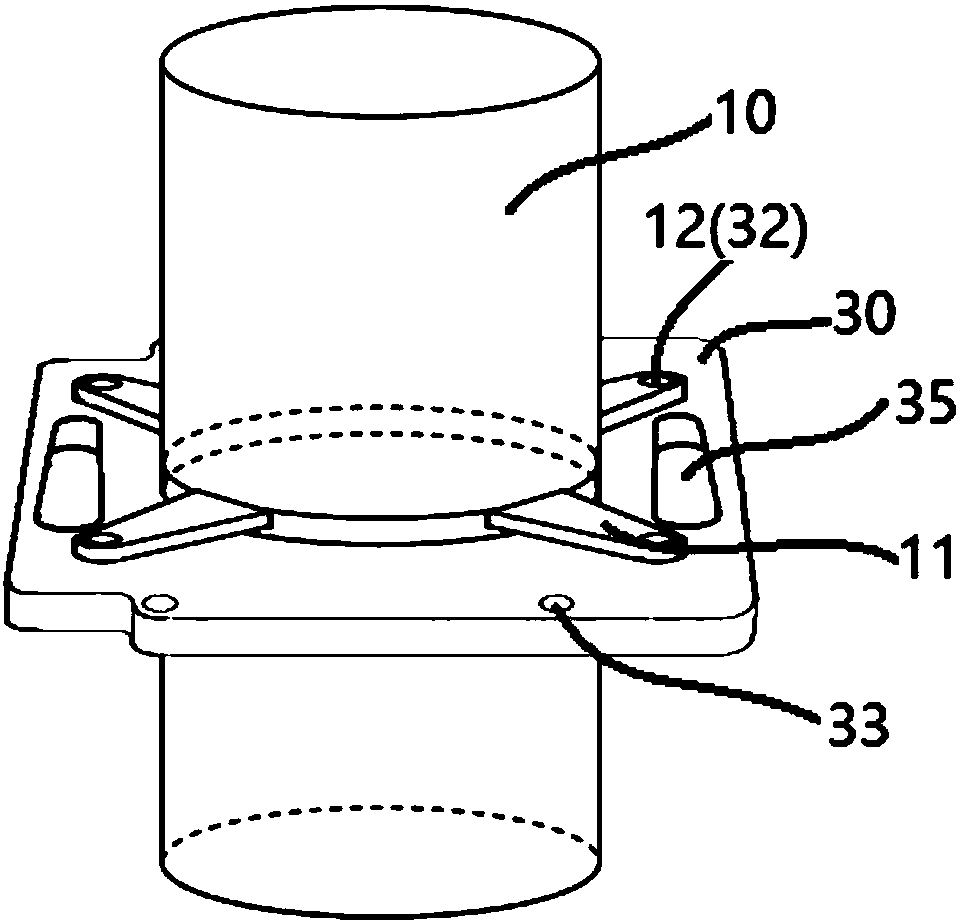

Packaging machine and discharge pipe assembly thereof

A technology for packaging machinery and discharge pipes, which is applied in packaging and other directions, and can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In addition, the terms "first", "second", etc. that may be used in the following descriptions are not intended to limit any order, and their purpose is only to distinguish individual components, parts, structures, elements, etc., and these independent components , parts, structures, elements may be the same, similar or different. At the same time, descriptions about orientation that may be used in the following descriptions, such as "upper", "lower", "inner", "outer", "left", "right", "radial", "axial", etc., Unless otherwise specified, it is only for the convenience of description, and does not intend to form any limitation on the technical solution of the invention.

[0019] The present invention generally relates to a packaging machine, which includes a control valve, a packaging mechanism, and may further include a feeding mechanism, a conveying mechanism, and many other suitable components, mechanisms or devices, etc. according to specific application environments....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com