Construction method of high-performance underwater blast-resistant concrete protective layer based on pouring technology

A construction method and concrete technology, applied to bridges, bridge parts, shipping equipment, etc., to achieve the effects of improving anti-knock performance, improving quality, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the construction method of the high-performance underwater anti-blast concrete protective layer based on the pouring technology involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024]

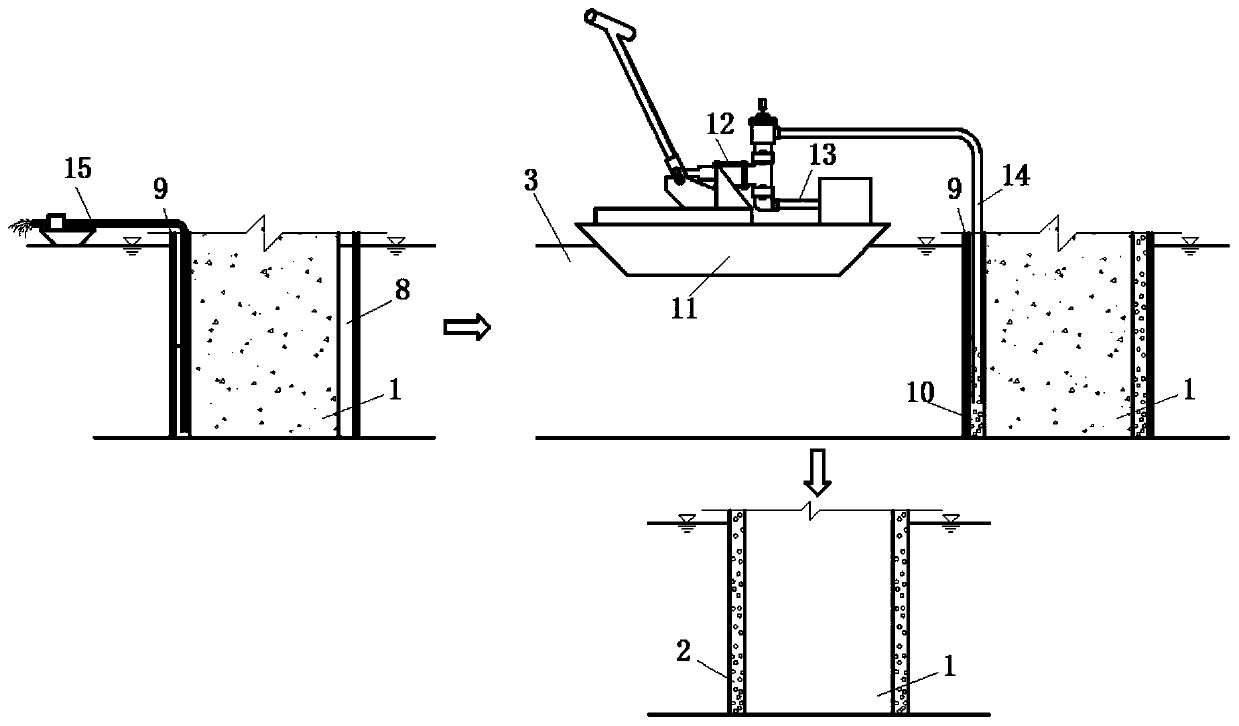

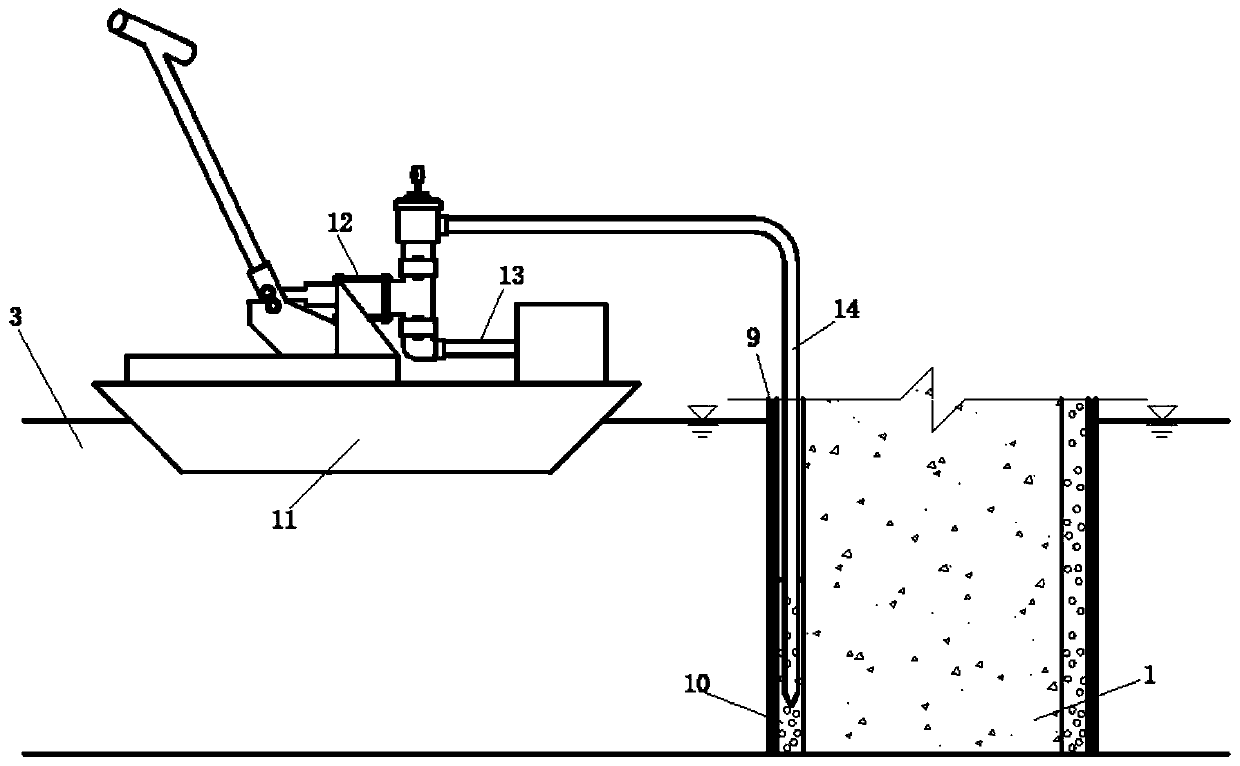

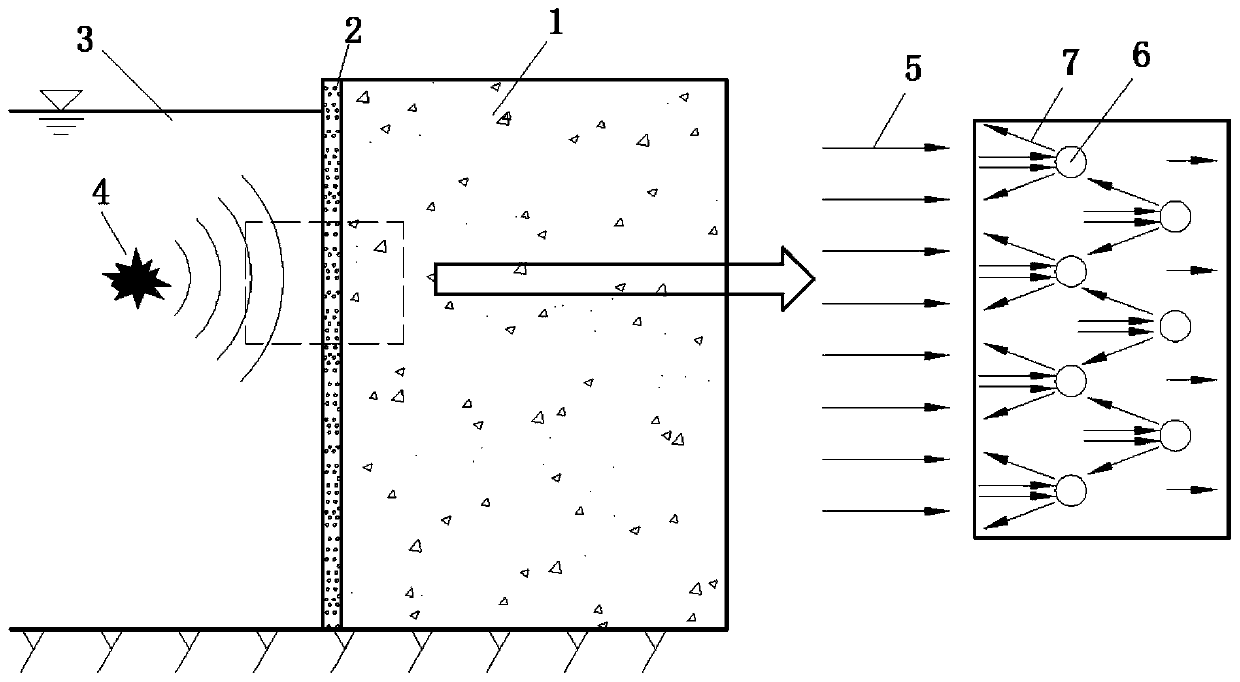

[0025] Such as Figures 1 to 3 As shown, the construction method of the high-performance underwater anti-blast concrete protective layer based on pouring technology provided by this embodiment includes the following steps:

[0026] Step 1. Use the water blocking member 9 to surround the surface to be protected of the wading structure 1, thereby isolating the external water body 3, and the water blocking member 9 is separated from the surface to be protected by a certain distance.

[0027] In this embodiment, the wading structure 1 is a bridge pier, and the water blocking member 9 used is spliced by steel sleeves, and the bottom is sealed with quick-setting mortar; distance for pouring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com