Ring beam construction method based on tool type shaping concrete ring beam formwork structure

A construction method and concrete technology, which are applied in building construction, construction material processing, construction, etc., can solve the problems of poor ring beam construction effect, low rigidity of formwork body, easy expansion of formwork or slurry leakage, etc., and achieve construction quality. Good, easy to fix, high mold support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

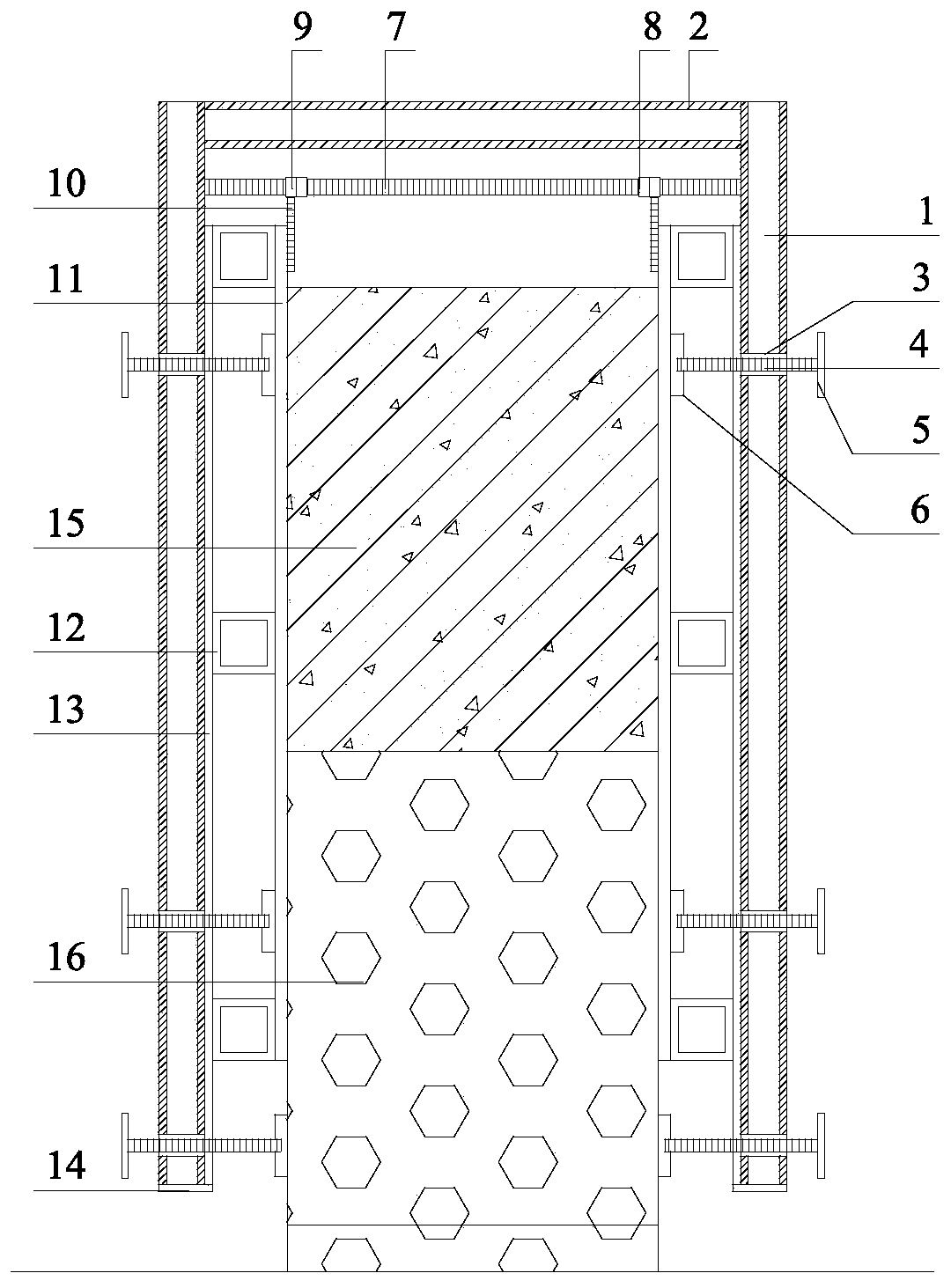

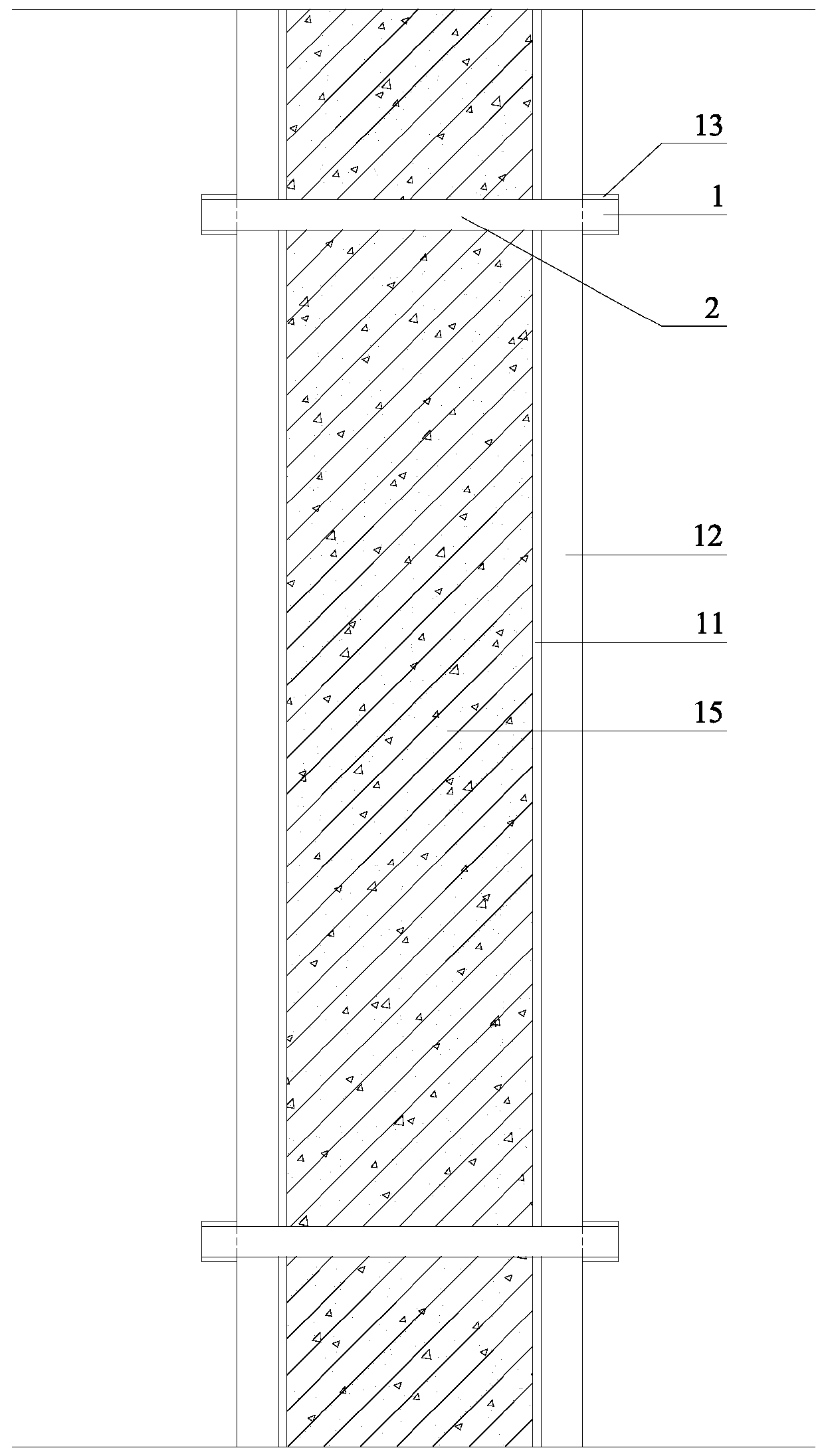

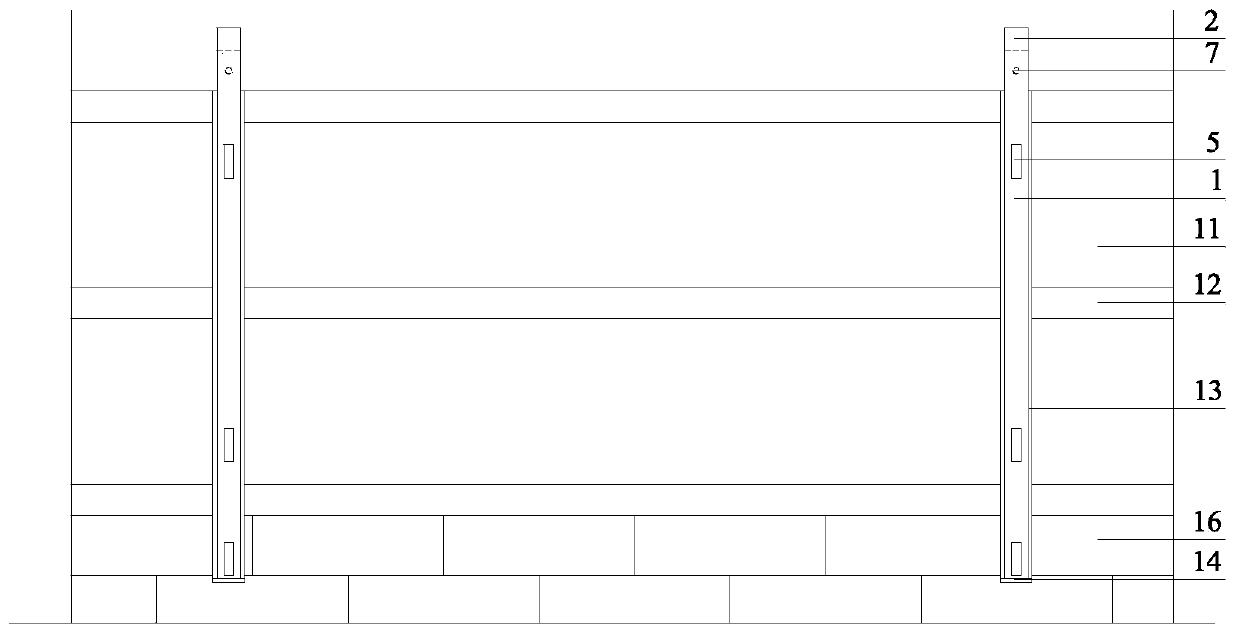

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

[0042] In the construction of a brick-concrete structure, the thickness of the brick wall is 240mm, and the cross-sectional size of the concrete ring beam is 240mm×300mm.

[0043] combined with Figure 1~3 As shown, the present invention relates to a tool-type shaped concrete ring beam formwork support structure, including formwork mechanisms, U-shaped frames and locking mechanisms symmetrically arranged on both sides of the brick wall. Each set of formwork mechanism includes formwork body 11, horizontal flute 12 and limit vertical groove 13. Formwork body 11 is made of aluminum formwork with a height of 540mm and a thickness of 10mm. 13 adopts channel steel of 40 × 35 × 5mm, the length of the channel steel is 615mm, the bottom height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com