Large-load aluminum alloy sliding panel structure of vertical air conditioner

A technology of sliding panels and vertical air conditioners, which is applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of no shock absorption device, large movement noise, and high cost, so as to improve the overall texture and improve the diameter of the air conditioner. Supporting force, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings.

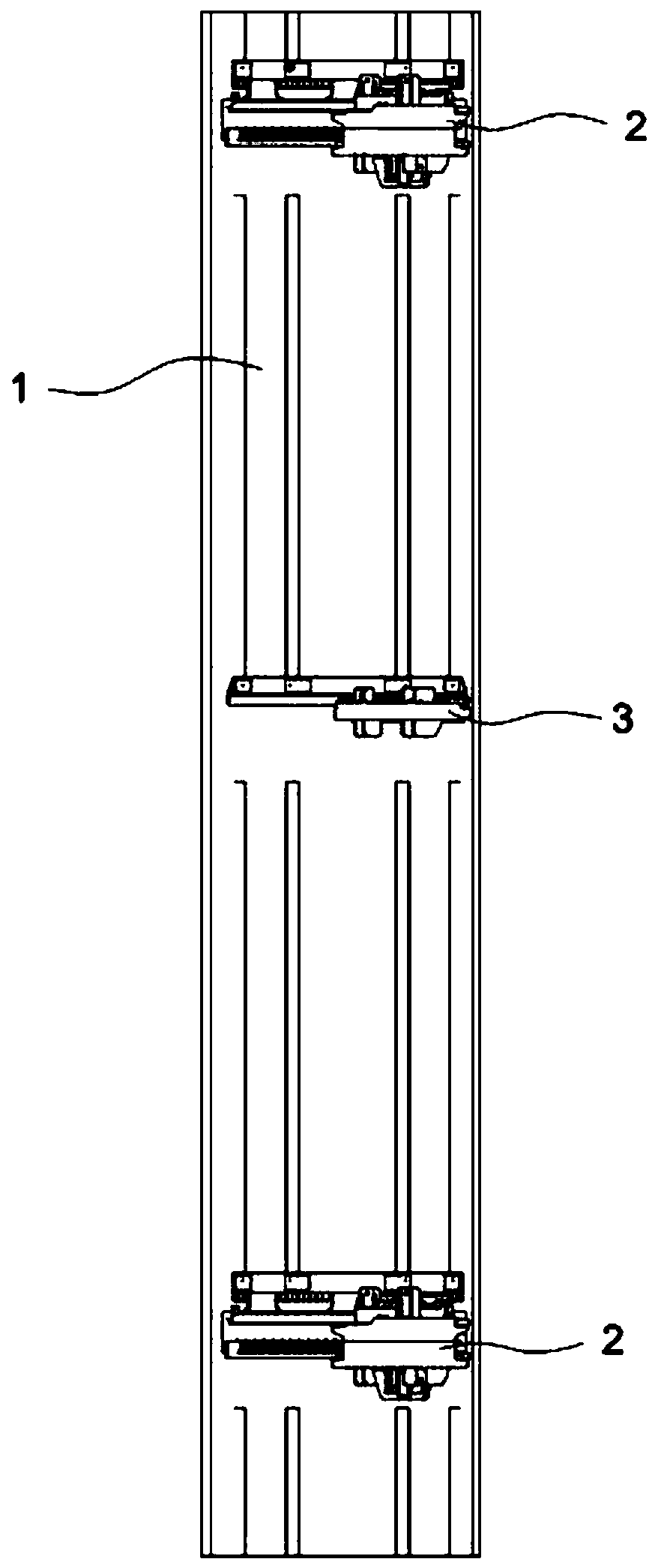

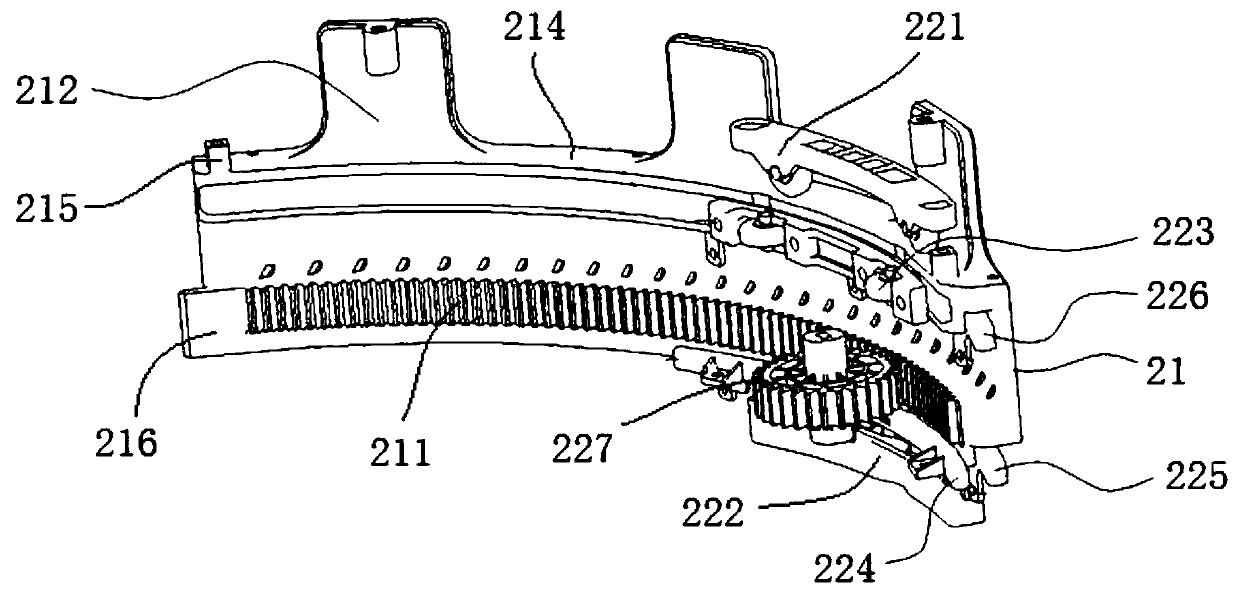

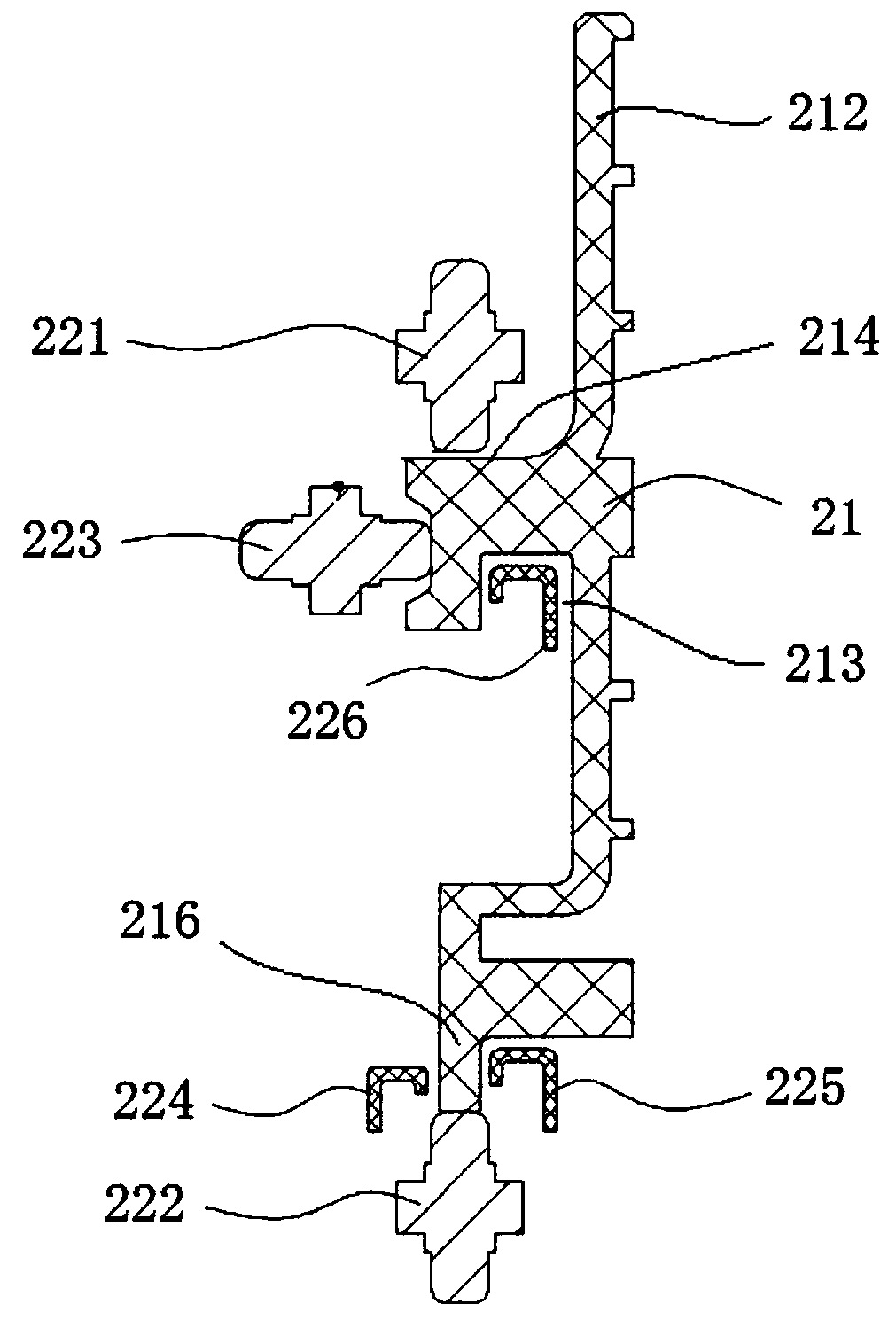

[0031] Such as figure 1 , figure 2 , image 3 As shown, the high-load aluminum alloy sliding panel structure of the vertical air conditioner of the present invention includes a sliding panel 1 and a driving device 2. The driving device 2 includes a rack plate 21 and a gear transmission assembly 22. The rack plate 21 is mounted on On the sliding panel 1, the gear transmission assembly 22 is installed on the air conditioner housing, and can drive the rack plate 21 to move under the action of a gear 227 and a guide mechanism, which includes a rolling bearing arranged on the gear transmission assembly 22 And the sliding rail, the rolling bearing includes a first bearing 221, a second bearing 222 and a third bearing 223, the first bearing 221 and the second bearing 222 are in contact with the upper and lower end surfaces of the rack plate 21, the third bearing 223 is in contact with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com