Drying device

A technology of drying device and supply device, applied in heating device, drying solid materials, drying and other directions, can solve the problems of low sludge viscosity and inability to collect sludge P, achieve uniformity of water content, improve drying efficiency, The effect of optimizing the drying state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

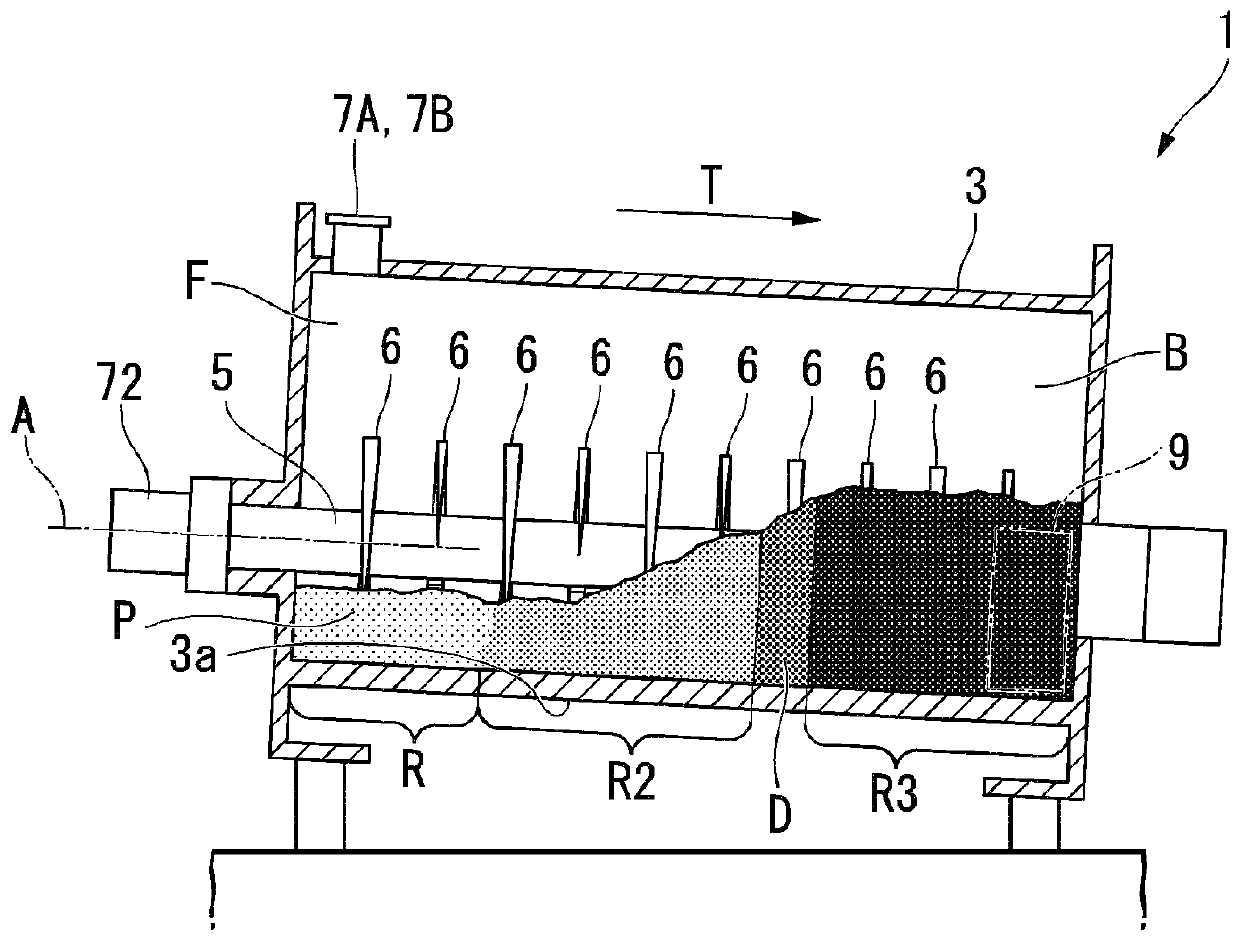

[0086] Hereinafter, a drying device 1 according to a first embodiment of the present invention will be described with reference to the drawings.

[0087] The drying device 1 of this embodiment is a highly viscous drying device for various biomass or waste such as sewage sludge, factory drainage sludge, food waste / kitchen waste, excrement sludge, livestock excrement, plant juice residue, etc. The water-containing matter (hereinafter referred to as sludge) is heated and dried (reduced moisture content) while being stirred and transported, so that they are discharged into powder and granular bodies. Sludge has, for example, a viscosity of 100 (Pa·s) or more and an ash content of 30 (%) or more.

[0088] In addition, as the measurement method of sludge, for example, if the ash content is used, the inorganic content in the input sludge solids can be obtained according to JIS M8812, and the viscosity measurement method can be obtained according to JIS K7199: Calculated in 1999 (ISO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com