Packaging process of LED display screen with double-layer glue-sealed laminated structure

A technology of LED display and packaging technology, which is applied in the field of display, can solve the problems of LED short circuit, module deformation, and uniform color of the whole screen, etc., and achieve the effects of thermal conductivity, moisture resistance, enhanced adhesion, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

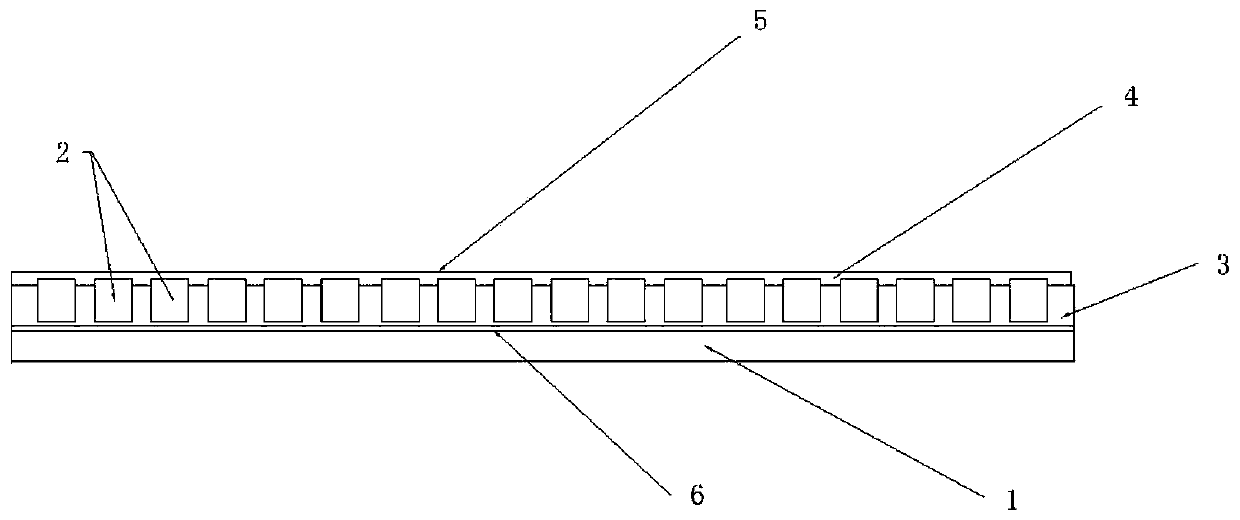

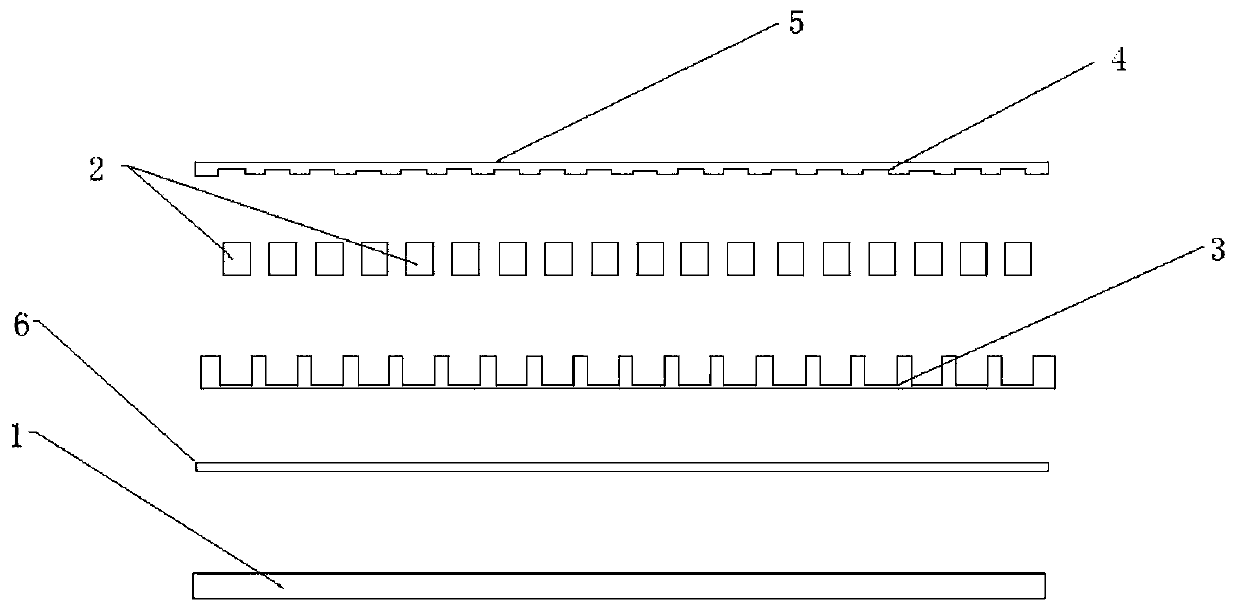

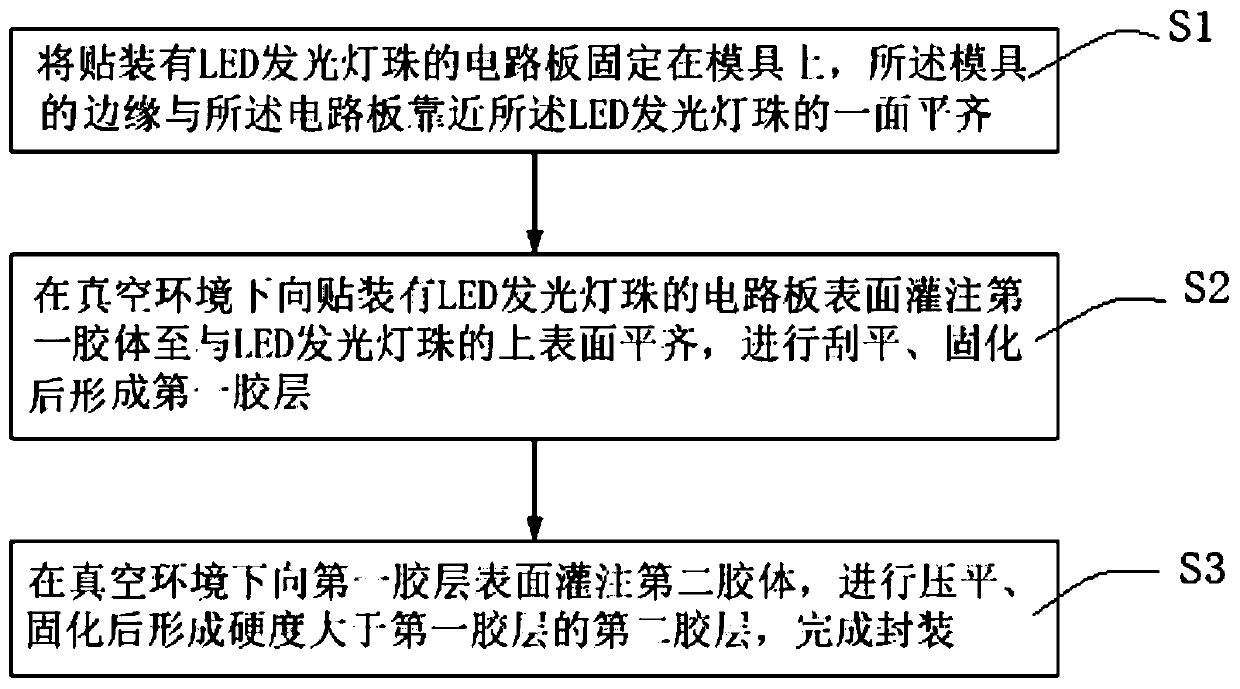

[0029] see Figure 1-Figure 3 , in order to achieve the above object, the present invention provides a LED display screen with a double-layer sealing structure, the LED display screen includes a circuit board 1 and LED light beads 2 mounted on the circuit board, and also includes The gap between the surface of 1 and the LED light bead 2 is filled with the first glue layer 3, and the upper surface of the LED light bead 2 is flush with the first glue layer 3 to form a flat surface; the upper surface of the first glue layer 3 is covered with the first glue layer Two adhesive layers 4 , and the hardness of the first adhesive layer 3 is less than that of the second adhesive layer 4 . And it is completed through the following packaging process:

[0030] S1 Preparation before packaging: Fix the circuit board mounted wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com