Power supply anti-backflow system of motor controller

A motor controller and anti-backflow technology, which is applied in the direction of current collectors, emergency power arrangements, battery circuit devices, etc., and can solve problems such as power backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

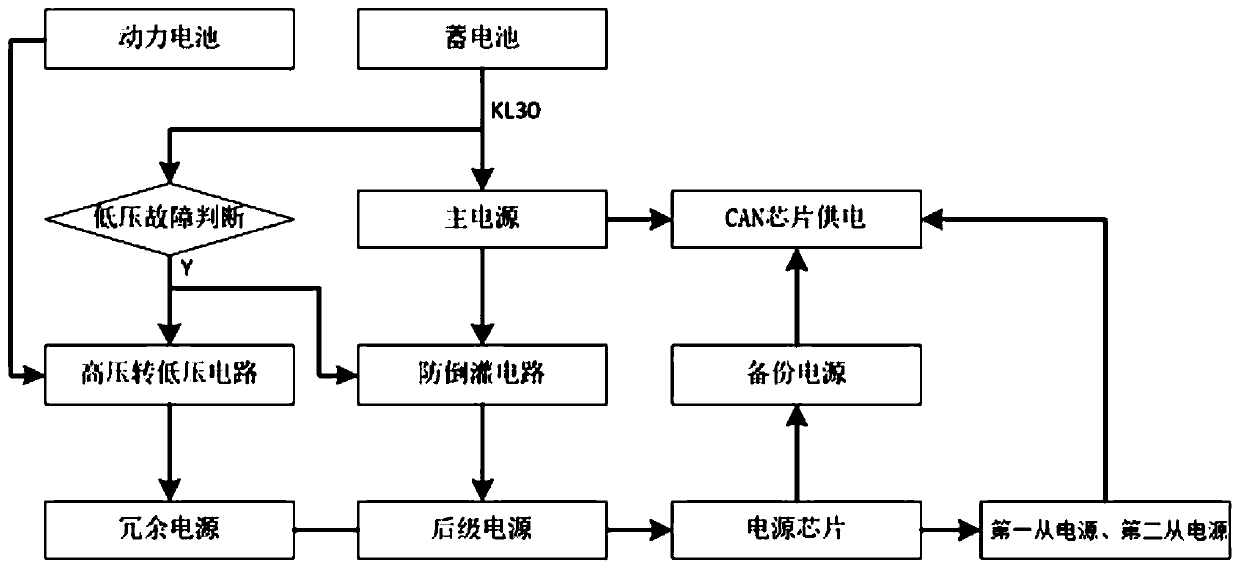

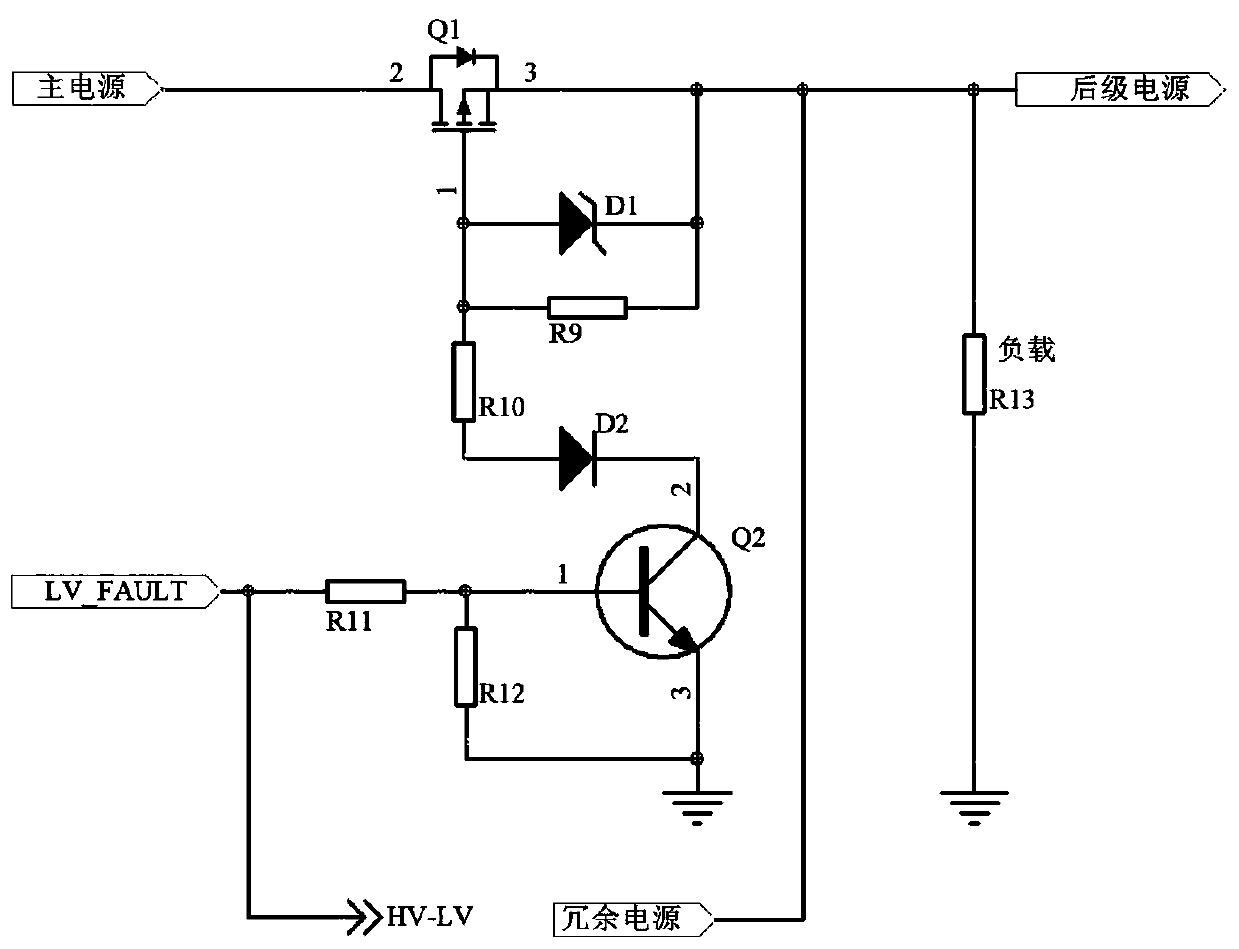

[0037] Such as figure 1 As shown, the power supply anti-backflow system of the motor controller of the present invention includes a battery, a main power supply, an anti-backflow circuit, a rear-stage power supply, and a slave power supply connected in sequence, and the positive pole of the battery is also connected with a low-voltage fault judgment circuit. The output end of the circuit is respectively connected to the anti-backflow circuit and the high-voltage to low-voltage circuit, the input end of the high-voltage to low-voltage circuit is connected to the power battery, and the output end is connected to the subsequent power supply through the redundant power supply.

[0038] It also includes a CAN transceiver chip power supply circuit, the CAN transceiver chip power supply circuit is respectively connected and powered by a main power supply and a slave power supply, and the slave power supply includes a first slave power supply and a second slave power supply. The latte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com