Device and method for collecting defective products of integrated circuit chip testing braiding machine

A chip testing and integrated circuit technology, which is applied to the collection device and field of defective products of integrated circuit chip testing and braiding machines, can solve problems such as troublesome handling of defective products, and achieve the effects of simple structure, reasonable design, and neat and orderly collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

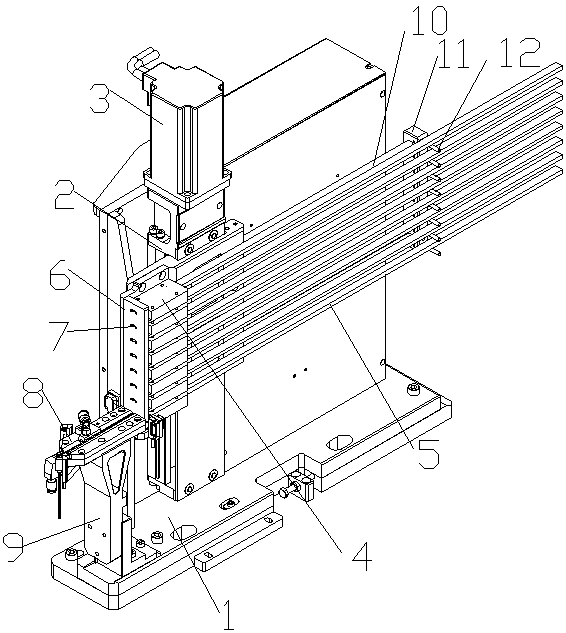

[0021] Such as Figure 1-2 As shown, a device for collecting defective products of an integrated circuit chip testing braiding machine includes a base installed on the table, and the base is sequentially equipped with a feeding guide rail and a receiving mechanism;

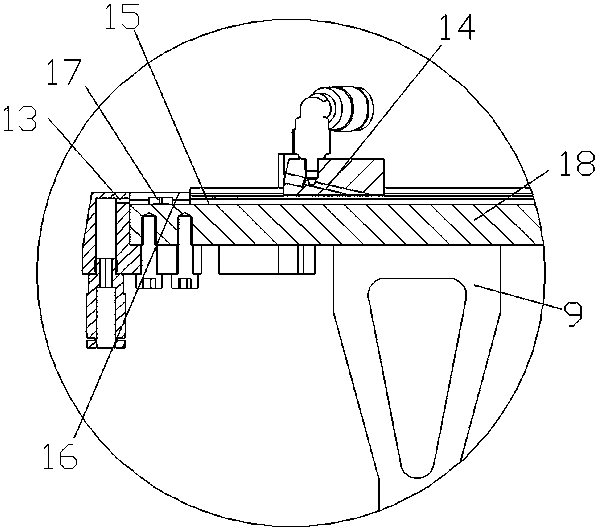

[0022] The receiving mechanism includes a receiving pipe, a linear slide table vertically installed on the frame, and several fixed blocks are sequentially arranged on the slide table of the linear slide table from top to bottom. There is a vertical plate on the input side, the fixed block and the vertical plate are locked on the sliding table by screws, and the channel holes are arranged on the vertical plate from top to bottom, and the channel holes correspond to the jacks on the fixed block one by one. The feeding end is inserted into the through hole and against the vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com