Forging method for Y-shaped block forging

A block and forging technology, applied in the field of forging, can solve the problems of long processing cycle, increased production cost, waste of raw materials, etc., and achieve the effects of stable product quality, reduced production cost, and reduced forging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

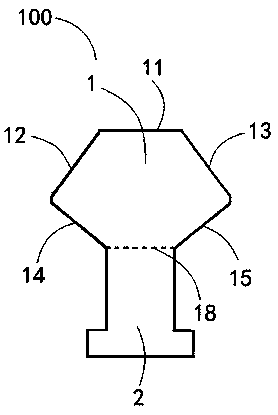

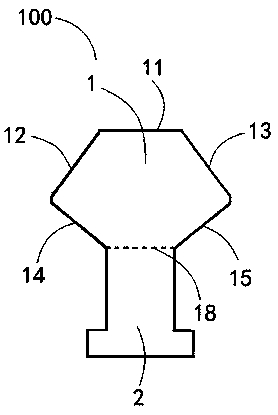

[0023] Such as Figure 1-2 Shown, a kind of forging method of Y type block forging, comprises the following steps:

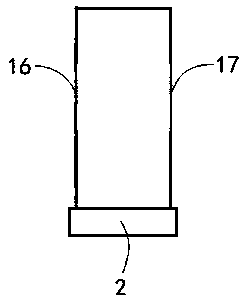

[0024] Step 1: Manufacture the same Y-shaped block template 100 as the Y-shaped block forging. The Y-shaped block template 100 includes a small head 2 and a big-headed square body 1. The big-headed square body 1 includes seven faces, respectively 11, 12, 13, 14, 15, 16, 17, two of the seven faces 16, 17 are symmetrical and parallel sides, the other five faces and the intersecting face 18 of the small head 2 and the big head square body 1 are surrounded The composite section is hexagonal and closed by two sides, and the bottom surface of the small head 2 has a block 21;

[0025] Step 2: Saw the billet into the riser and nozzle; then heat the billet in the furnace, heat it to the initial forging temperature of 1250°C, and heat it for 7 hours before forging; Meter. Saw the riser and nozzle from the billet is to saw the riser and nozzle from the steel ingot.

[...

Embodiment 2

[0029] A method for forging a Y-shaped block forging, comprising the following steps:

[0030] Step 1: Manufacture the same Y-shaped block template 100 as the Y-shaped block forging. The Y-shaped block template 100 includes a small head 2 and a big-headed square body 1. The big-headed square body 1 includes seven faces, respectively 11, 12, 13, 14, 15, 16, 17, two of the seven faces 16, 17 are symmetrical and parallel sides, the other five faces and the intersecting face 18 of the small head 2 and the big head square body 1 are surrounded The composite section is hexagonal and closed by two sides, and the bottom surface of the small head 2 has a block 21;

[0031] Step 2: Saw the billet into the riser and nozzle; then heat the billet in a furnace to the initial forging temperature of 1270°C, and keep it warm for 3.5 hours before forging;

[0032] Step 3: When forging, set a certain preset forging ratio, the preset forging is set to 3.5, pull out the flat square with high pres...

Embodiment 3

[0035] A method for forging a Y-shaped block forging, comprising the following steps:

[0036] Step 1: Manufacture the same Y-shaped block template 100 as the Y-shaped block forging. The Y-shaped block template 100 includes a small head 2 and a big-headed square body 1. The big-headed square body 1 includes seven faces, respectively 11, 12, 13, 14, 15, 16, 17, two of the seven faces 16, 17 are symmetrical and parallel sides, the other five faces and the intersecting face 18 of the small head 2 and the big head square body 1 are surrounded The composite section is hexagonal and closed by two sides, and the bottom surface of the small head 2 has a block 21;

[0037] Step 2: Saw the billet into the riser and nozzle; then heat the billet in a furnace to the initial forging temperature of 1250°C, and then forge after 10 hours of heat preservation;

[0038] Step 3: When forging, set a certain preset forging ratio, the preset forging ratio is set to 4, flatten the square with high p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com