Composite non-woven fabric and printing pressing method thereof

A non-woven and spunbond non-woven technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of easy color fading, single color, reduce the composite fastness of non-woven fabrics, etc. Uniform effect of compound fastness and pattern clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

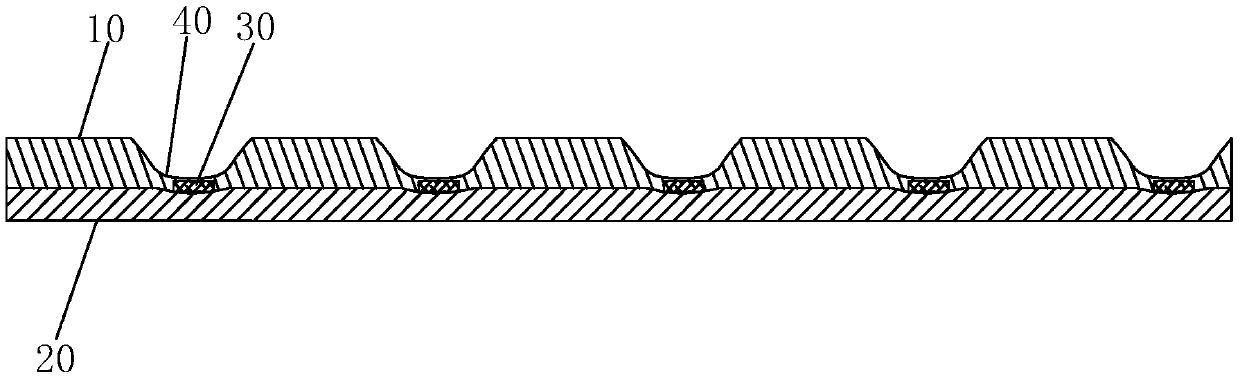

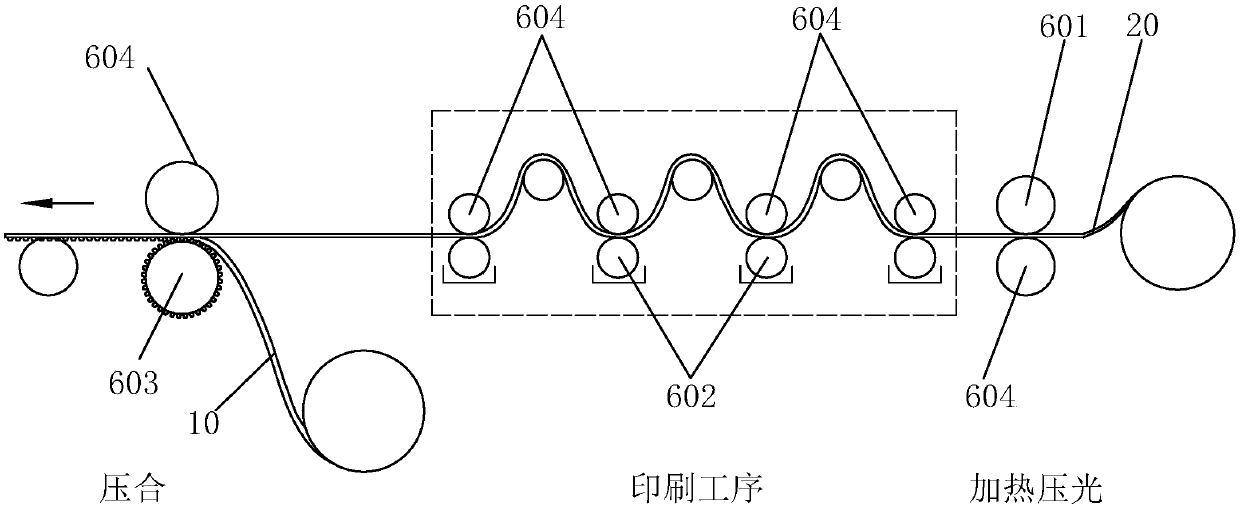

[0031] see figure 1 , a composite non-woven fabric, including a non-woven surface layer 10 and a printing substrate layer 20, the top surface of the printing substrate layer 20 is printed with several ink areas 30, and the several ink areas 30 are distributed at intervals. The non-woven surface layer 10 is compounded on the top surface of the printing substrate layer 20 and forms a pressing area 40 therewith, and the pressing area 40 overlaps with the ink area 30 . In this way, the pattern display of the ink area 30 is consistent with the effect after hot pressing, so as to avoid that some parts of the printed pattern are hot pressed, and some places are not hot pressed, resulting in inconsistent colors and effects.

[0032] In this embodiment, the printing substrate layer is a calendering-treated printing substrate layer. The non-woven surface layer 10 is bonded to the top surface of the printing substrate layer 20 by thermocompression or ultrasonic bonding. The printing s...

Embodiment 2

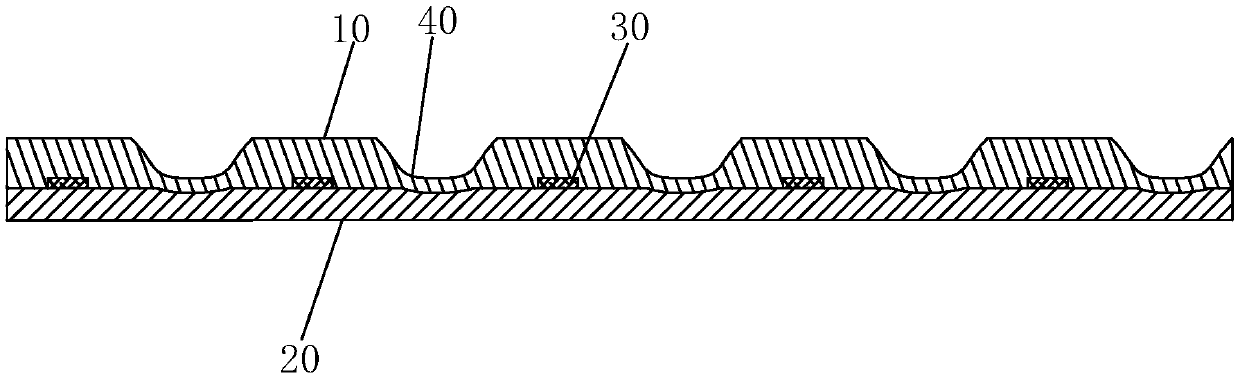

[0039] see image 3 , a composite non-woven fabric, comprising a non-woven fabric surface layer 10 and a printing substrate layer 20, the top surface of the printing substrate layer 20 is printed with several ink areas 30, and the several ink areas 30 are distributed at intervals; the non-woven fabric surface The layer 10 is thermally pressed on the top surface of the printing substrate layer 20 to form a pressing area 40 thereon, and the pressing area 40 and the ink area 30 do not overlap with each other. The ink layer with the printed pattern is staggered from the pressing area 40, so that the display effect of the ink layer is not affected by the pressing, avoiding that some places of the printed pattern are hot-pressed, and some places are not hot-pressed, resulting in color, The effect is inconsistent.

[0040] In this embodiment, the printing substrate layer is a calendering-treated printing substrate layer. The non-woven surface layer 10 is bonded to the top surface o...

Embodiment 3

[0046] see Figure 4 , a composite non-woven fabric and its printing and lamination method, its main structure and method are the same as those in Embodiment 1, the difference is that an air cushion area 50 with a cavity can also be formed between two adjacent lamination areas 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com