A laser film production system, process method and laser label

A production system and technology of laser film, applied in printing process, copying/marking method, exposure device of photoplate making process, etc., can solve the problems of laser film not being resistant to ink erosion, poor ability to block foreign objects, etc., to achieve resistance to ink erosion barrier Effects of Alien Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

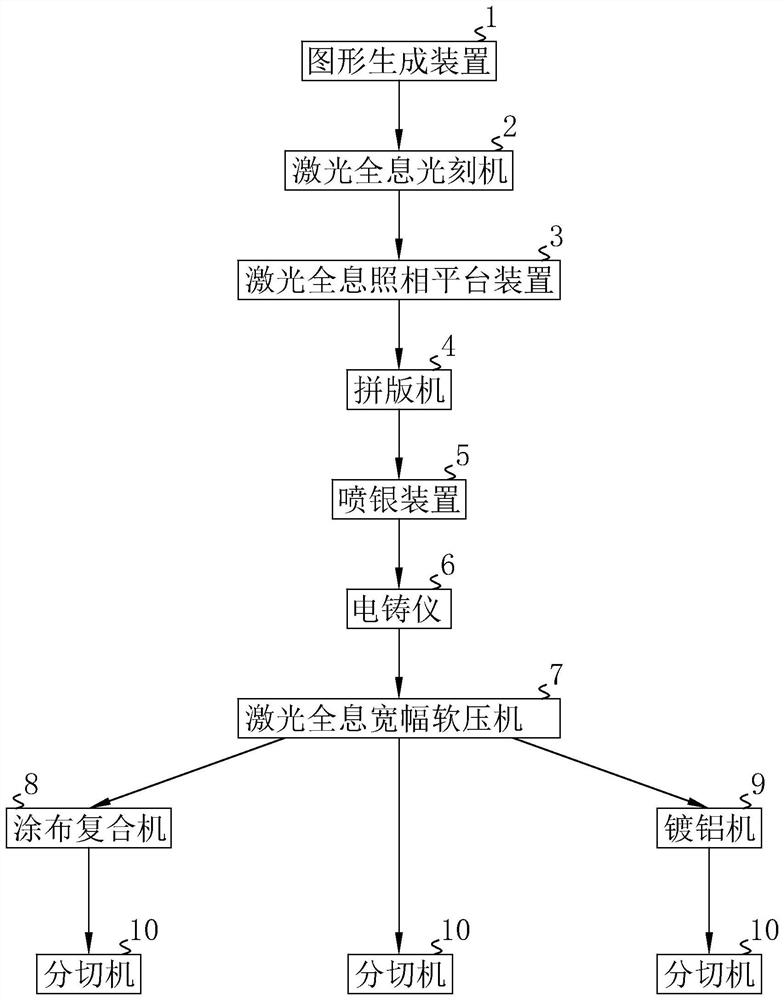

[0054] A laser film production system, such as figure 1 As shown, it includes a graphic generation device 1, a laser holographic lithography machine 2, a laser holographic platform device 3, an imposition machine 4, a silver spray device 5, an electroforming instrument 6, a laser holographic wide soft press machine 7, and a coating compound machine 8 or aluminum plating machine 9, and slitting machine 10;

[0055] The graphic generation device 1 is used to scan the image and generate graphic data corresponding to the image;

[0056] Laser holographic lithography machine 2 is used to receive graphic data and realize laser graphics, and perform lithography on the original plate;

[0057] The laser holographic platform device 3 is used to record laser patterns on the photosensitive material to realize the shooting of the laser patterns. The laser holography platform device 3 includes a laser photolithography room, a batching room, a plate library for storing master plates, a pl...

Embodiment 2

[0066] A method for producing a laser film, comprising the steps of:

[0067] Step S1: scan the image and generate graphic data corresponding to the image.

[0068] Step S2: receiving graphic data and realizing laser graphics, and performing photolithography on the original plate.

[0069] Step S3: Record the laser pattern on the photosensitive material to realize the shooting of the laser pattern. Step S3 includes: Step S31: laser lithography, making laser digital light-changing images and laser original plates. Step S32: batching. Step S33: Store the master. Step S34: taking pictures on the platform. Step S35: Darkroom development of the laser image.

[0070] Step S4: enlarging the laser pattern imposition into a larger format laser group plate for molding;

[0071] Step S5: Form a uniform and dense conductive layer on the surface of the non-metallic material during photolithography, photography and imposition.

[0072] Step S6: making a laser holographic metal mold e...

Embodiment 3

[0077] A laser label, comprising a backing paper and a laser sticker arranged on the backing paper and made by using the system in Embodiment 1, the side of the laser sticker away from the backing paper is set as a diamond surface layer, and the diamond surface layer is provided with at least three layers of Depth of field, depth of field includes the deepest layer, the middle layer and the most surface layer. The deepest layer is provided with a scattering surface, which is used to scatter light to multiple angles, and the middle layer is provided with a colored surface, the viewing angle area of the colored surface overlaps with that of the scattering surface, so that the eyes can see the intermediate layer from multiple angles is colored. Both middle and deepest layers have colored depth of field. The outermost layer is provided with a color layer and a bright silver layer located on the same layer and interlaced. The bright silver layer is made of sand silver and is a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com