Lifting mechanism for landing gear flexible intelligent mounting system

A technology of installation system and lifting mechanism, which is applied in the field of lifting mechanism, can solve the problems of limited use space, inconvenient maintenance and guarantee work, long working hours, etc., and achieve the effects of reducing storage space, convenient maintenance and repair, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

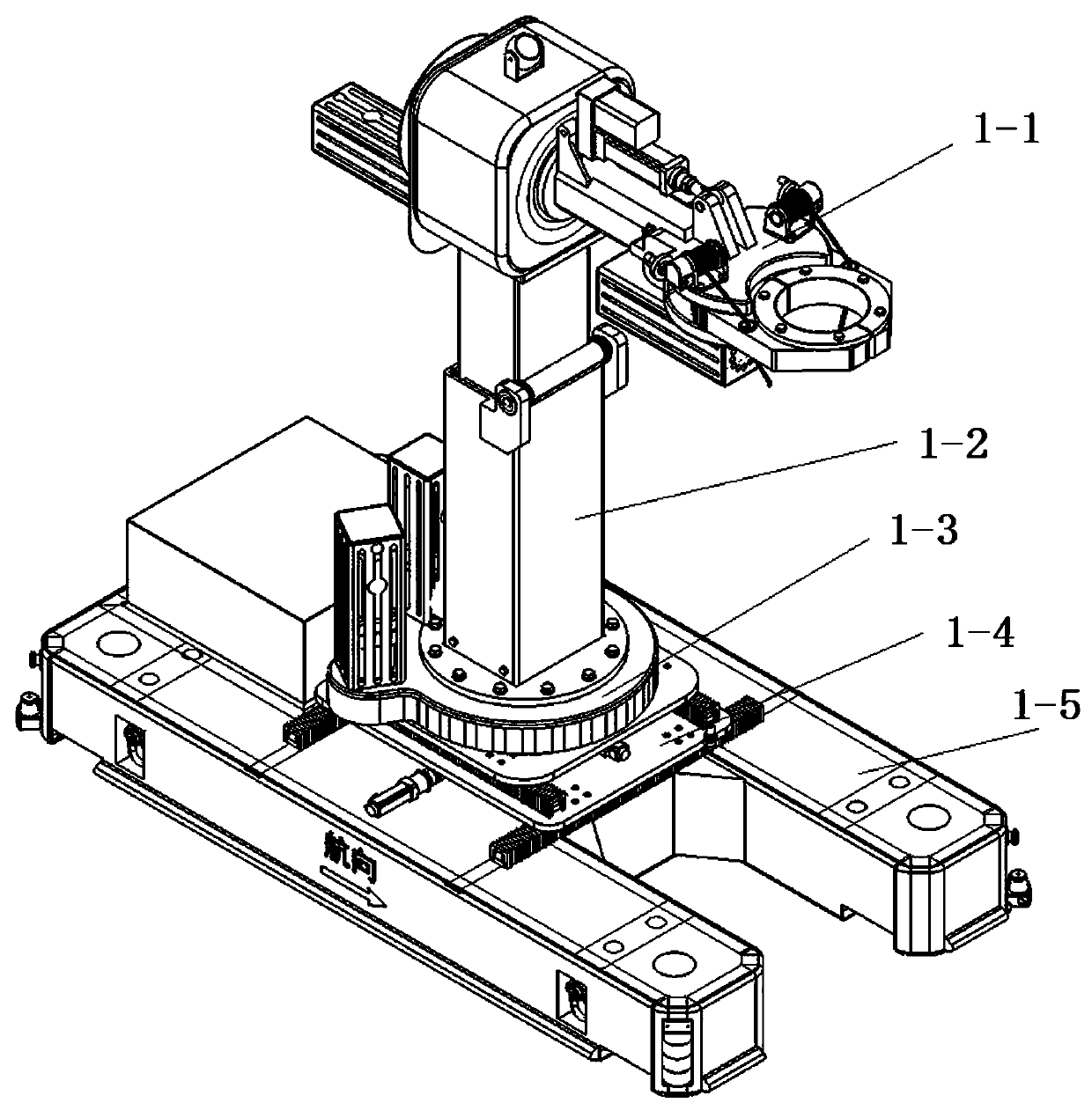

[0019] The flexible and intelligent installation system for aircraft landing gear includes a mechanical arm 1-1, a Z-axis lifting mechanism 1-2, a C-axis rotating mechanism 1-3, an XY translation mechanism 1-4, and a traveling vehicle 1-5.

[0020] The mechanical arm 1-1 includes a bearing seat 12-6, an electric push rod 12-8, a claw seat 12-12, a support arm 12-7 and a B-axis servo motor 12-1. A bearing 12-4 is installed in the bearing seat 12-6, the outer ring of the bearing 12-4 is fixedly connected with the inner wall of the bearing seat 12-6, and the support arm 12-7 is inserted into the inner ring of the bearing 12-4 and is fixedly connected. On the support arm 12-7, a B-axis gear 12-3 is sleeved by screws. The B-axis gear 12-3 is provided with a plurality of teeth in the set angle range, so that the support arm 12-7 can rotate within the set angle. The housing of the B-axis servo motor 12-1 is fixed on the bearing seat 12-6, and the gear on the power output shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com