Tensioning and anchoring device for multi-layer pre-stressed fiber cloth reinforced beam

An anchoring device and fiber cloth technology, which is applied in the field of tensioning and anchoring devices for multi-layer prestressed fiber cloth reinforced beams, can solve the problems of unequal lengths of multi-layer fiber cloth, cumbersome construction methods, and low anchoring efficiency, and achieve operational Convenience, good reinforcement effect, and the effect of improving anchorage reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

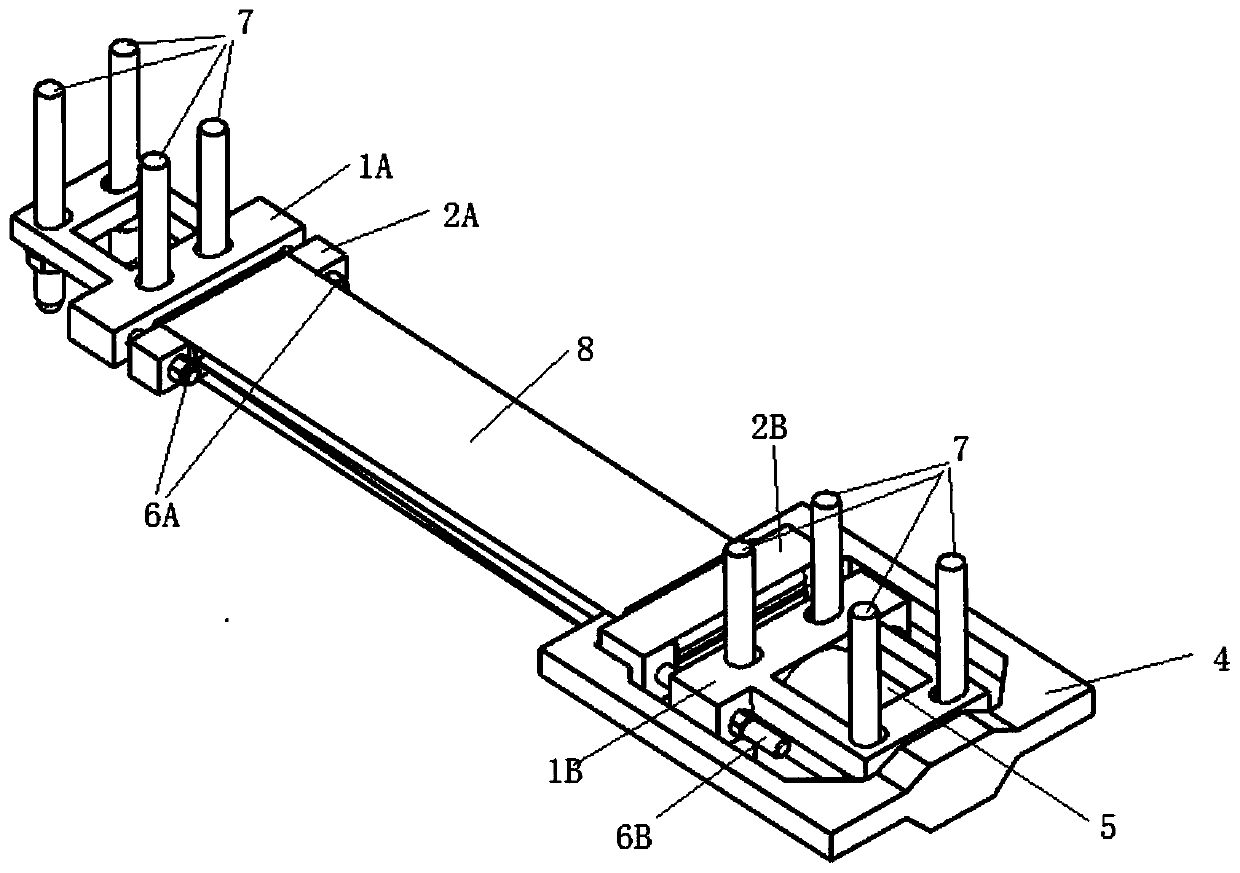

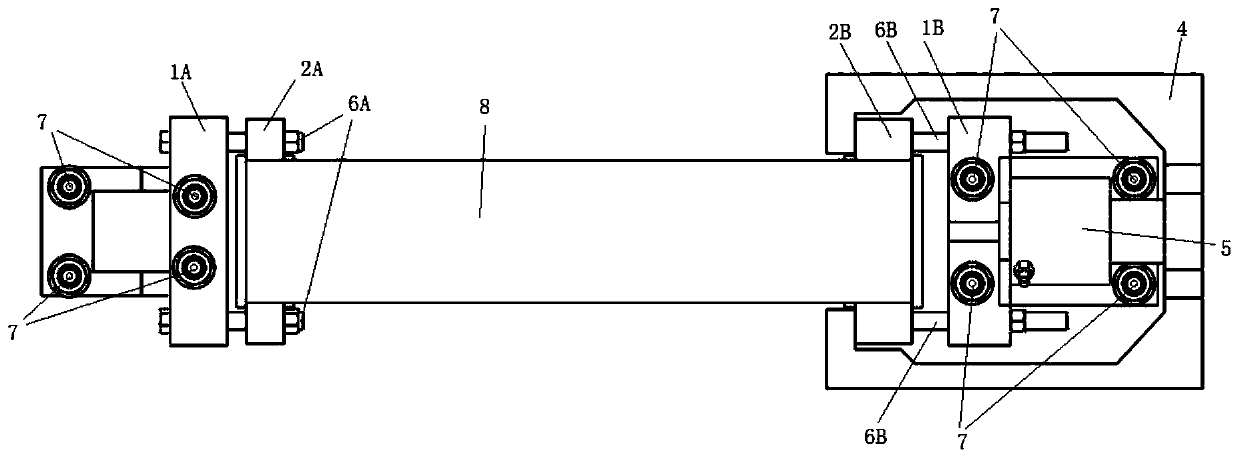

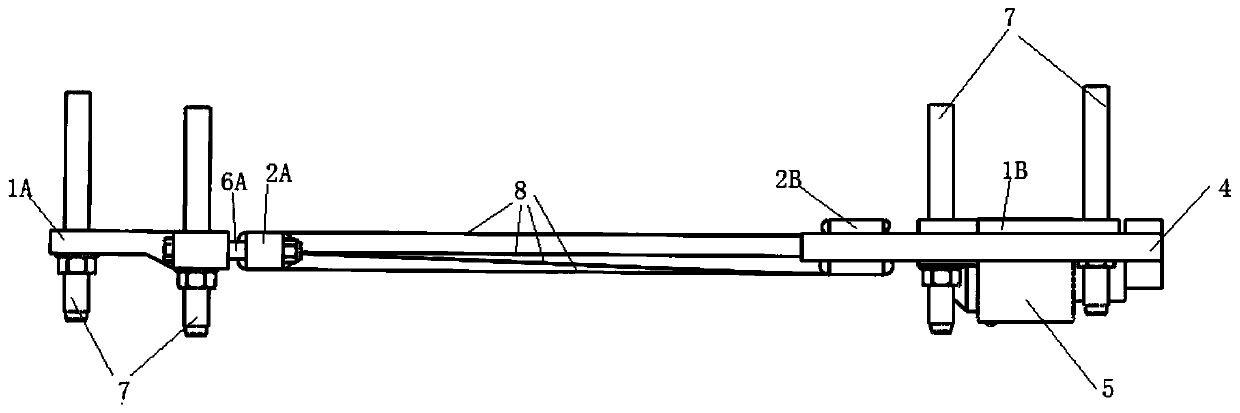

[0052] Such as Figure 1-28 As shown, this embodiment utilizes a tensioning and anchoring device for a multi-layer prestressed fiber cloth reinforced beam of the present invention, takes a reinforced concrete beam as the reinforcement object, and adopts eight layers of prestressed carbon fiber cloth to reinforce it, and the width of the carbon fiber cloth is 150mm, as follows:

[0053]A tensioning and anchoring device for multi-layer prestressed fiber cloth reinforced beams, including a fixed end support 1A, a tension end support 1B, a fixed end anchor 2A, a tension end anchor 2B, two Clip 3, two anchor short screws 6A, two anchor long screws 6B, eight chemical bolts 7, fiber cloth 8, prestressing frame 4 and jack 5.

[0054] Such as Figure 4 As shown, the fixed end support 1A is T-shaped. There are four oval through-holes I1A1 for installing chemical bolts 7 on it, and a circular anchor hole I1A2 for connecting with fixed-end anchorage 2A on each side.

[0055] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com