Monitoring blade bearing

A bearing and blade technology, applied in the field of blade pitch bearing, can solve the problems of pitch error, inaccurate blade bearing, non-optimal maintenance work plan, etc., and achieve the effect of precise or accurate condition monitoring or diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

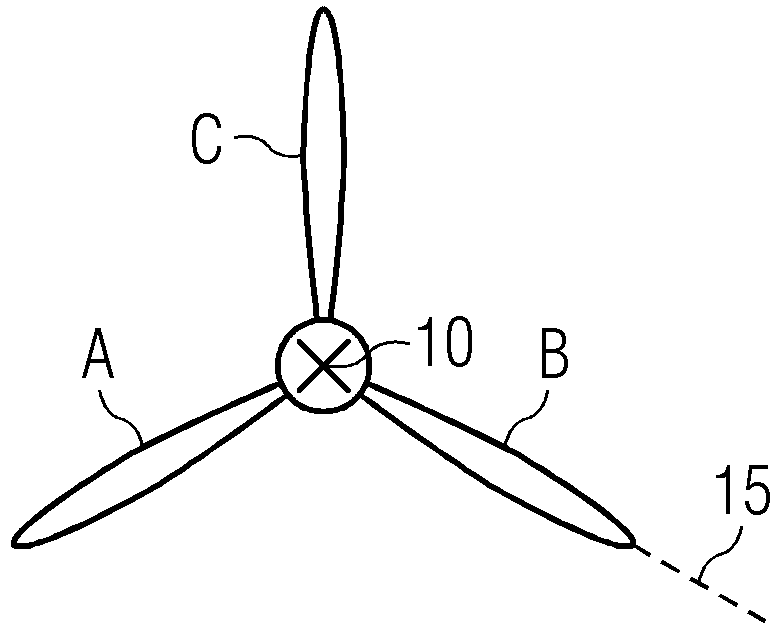

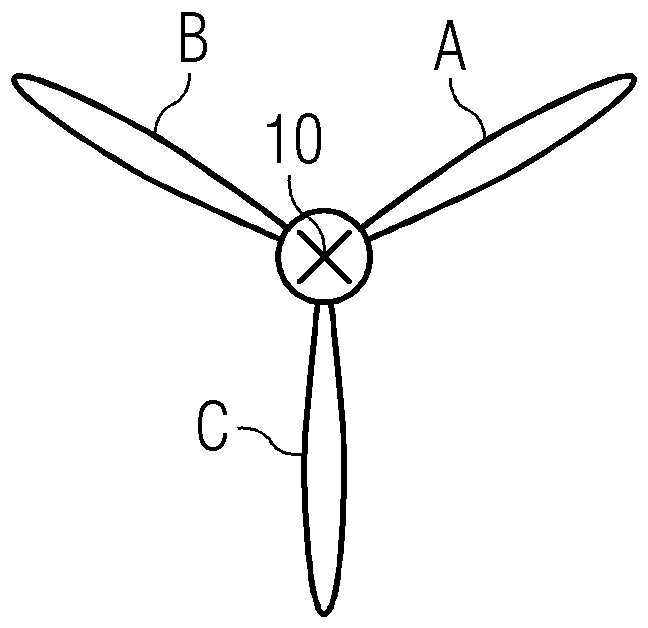

[0045] exist figure 1 The wind turbine 1 shown schematically in the figure comprises a wind turbine tower 3, a nacelle 5 mounted on top of the wind turbine tower, the nacelle 5 housing a generator 7 with a rotating shaft 9 coupled to a wind turbine installed there Hub 11 of a plurality of rotor blades 13 . At least one rotor blade 13 of the wind turbine 1 comprises a rotor blade bearing 17 according to an embodiment of the invention enabling rotation of the airfoil 14 of the rotor blade 13 about the longitudinal axis 15 relative to the hub 11 .

[0046] figure 2 Schematically shown (in a side view along the longitudinal axis 15 of the rotor blade) is a blade bearing 17 according to an embodiment of the invention, which may for example be included in a wind turbine 1 in order to align the airfoil of the rotor blade 13 14 is rotatably connected to hub 11 allowing pitching of airfoil 14 of rotor blade 13 about its longitudinal axis 15 . The rotor blade bearing 17 comprises an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com