A Compensation Method for Angle Measuring Error of Circular Grating

An error compensation and circular grating technology, applied in the field of circular grating angle measurement error compensation, can solve problems such as high cost and immature commercial products, and achieve the effects of saving costs, improving product reliability, and improving angle measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

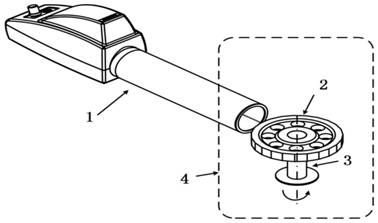

[0029] Such as figure 1 As shown, a circular grating angle measurement error compensation method includes the following steps:

[0030] 1) After placing the circular grating angle measurement system in a constant temperature box 4 at 10°C and waiting for 2 hours, use the photoelectric autocollimator 1 and the hardware data acquisition system to collect the circular grating angle measurement system in combination with the polygonal prism 2 installed on the shaft body 3. Angle data; continue to heat up, measure a set of angle measurement data every 5°C until the set temperature is reached; set the temperature range of the thermostat to 10-40°C. A shaft body is arranged on the rotary joint of the circular grating angle measurement system, and a single reading head is installed on the shaft body.

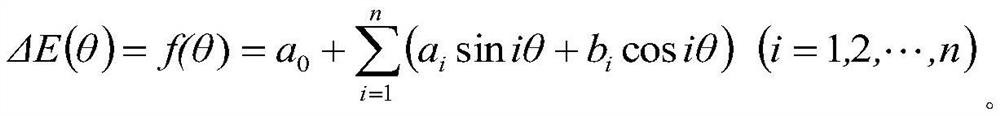

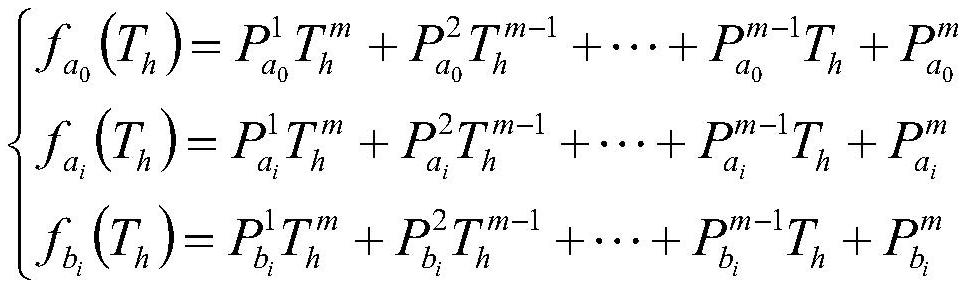

[0031] 2) Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com