Sub-pixel edge detection method and system

A sub-pixel edge detection method technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of inability to meet industrial production requirements, low detection accuracy, poor anti-noise performance, etc., and achieve good anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

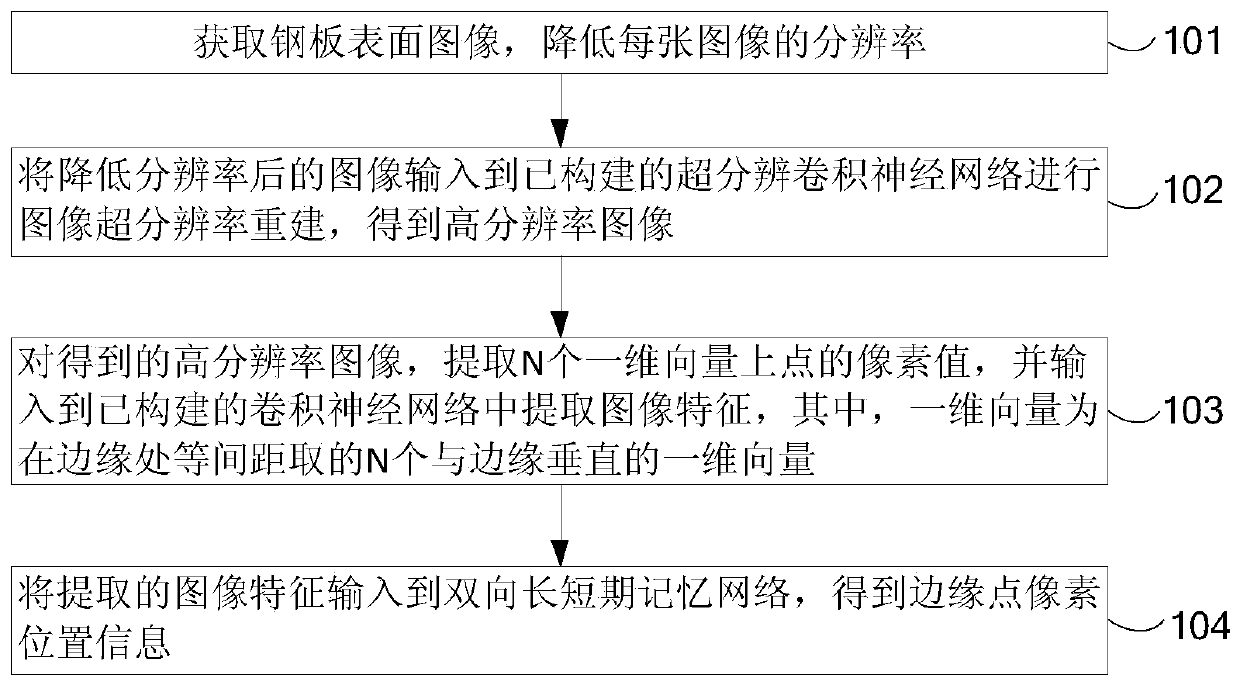

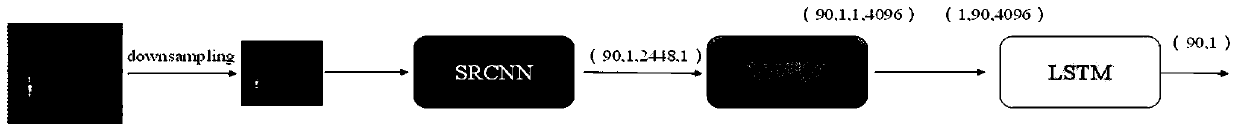

[0041] Such as figure 1 As shown, the sub-pixel edge detection method provided by the embodiment of the present invention includes:

[0042] S101, acquire the surface image of the steel plate, and reduce the resolution of each image;

[0043] S102, inputting the reduced-resolution image to the constructed super-resolution convolutional neural network (Super-Resolution Convolutional Neural Network, SRCNN) for image super-resolution reconstruction to obtain a high-resolution image;

[0044] S103, for the obtained high-resolution image, extract the pixel values of the points on N one-dimensional vectors, and input them into the constructed convolutional neural network to extract image features, wherein the one-dimensional vectors are taken at equal intervals at the edge N one-dimensional vectors perpendicular to the edge;

[0045] S104, inputting the extracted image features into a bidirectional Long Short-Term Memory (LSTM) network to obtain edge point pixel position informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com