Friction-stir welding method and friction-stir welding system

A technology of friction stir and welding methods, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of affecting control accuracy, welding pressure, and inability to ensure high-quality welding, etc., to achieve good weld formation, Guarantee the effect of welding seam forming and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

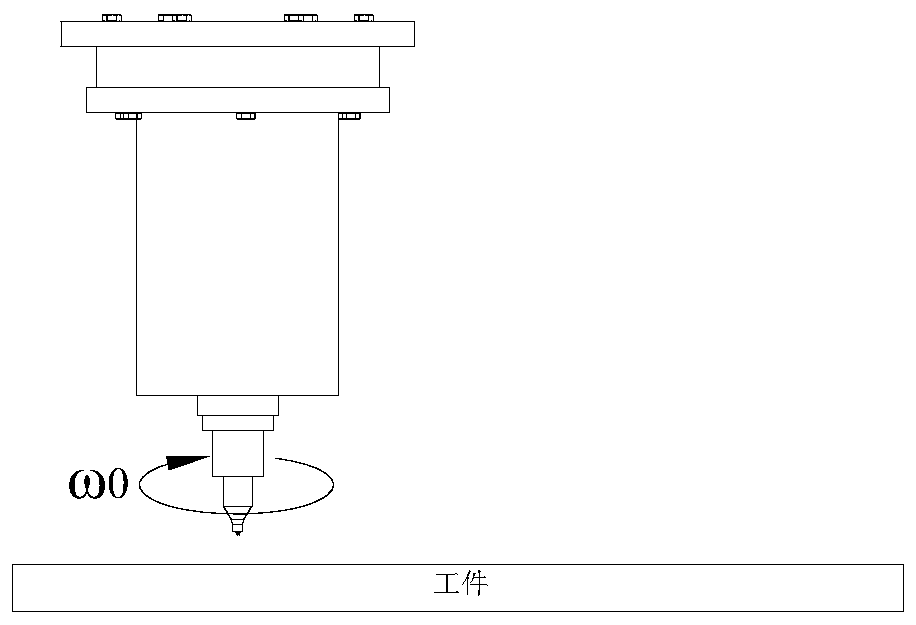

[0080] This embodiment provides a friction stir welding method, the inclination angle of the workpiece is 30 degrees, and the welding process includes the following steps:

[0081] (1) Stirring head pressure calibration: extract the pressure value Pz monitored by the multi-dimensional mechanical sensor, and calibrate the actual pressure P on the stirring head according to this pressure value, P=Pz-G×sinθ. Among them, G is the sum of the gravity of the main shaft, tool handle and stirring head, θ is the angle between the axis of the stirring head and the horizontal plane at this time is equal to 30 degrees, and the workpiece is located above the stirring head, that is, θ=π / 6.

[0082] (2) Calibration of the forward resistance of the stirring head: extract the resistance value Fx of the multi-dimensional mechanical sensor in the welding forward direction, and calibrate the actual forward resistance F of the stirring head according to this resistance value, F=Px+GF cosθ. Among th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap