A kind of preparation method of anti-wax deposition pipeline

A pipeline and wax-proof technology, applied in coatings, polyether coatings, etc., can solve problems such as high energy consumption, achieve resource and energy conservation, reduce turbulence, and reduce water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The inner wall of the HDPE pipe was treated with a plasma processor, and the treatment conditions were: treatment at 80V for 90s.

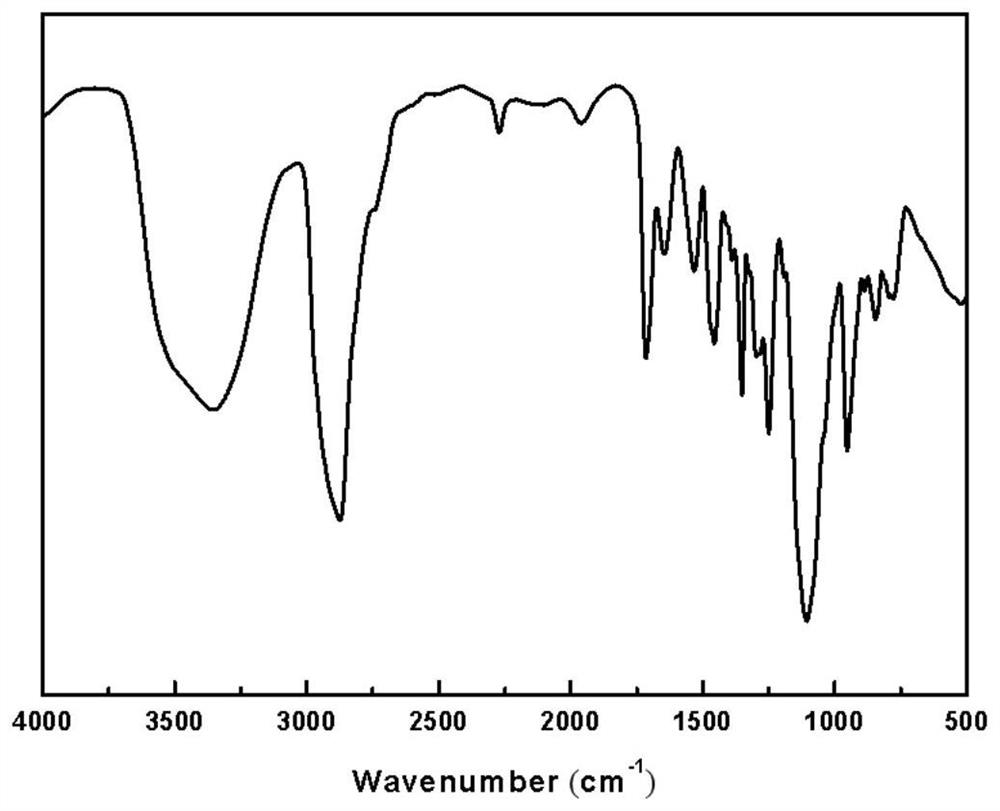

[0029] 26.45g of PEG 600 Dry in a vacuum oven at 60°C for 12h, add the treated PEG to a 50ml round-bottomed flask, heat it to 75°C in an oil bath, while continuously passing nitrogen, and slowly add 7.15g of IPTS dropwise to the In the flask, the product PEG-(SiR was obtained after 12h of reaction 2 O) 3 (The infrared spectrum of the product is shown in figure 1 shown).

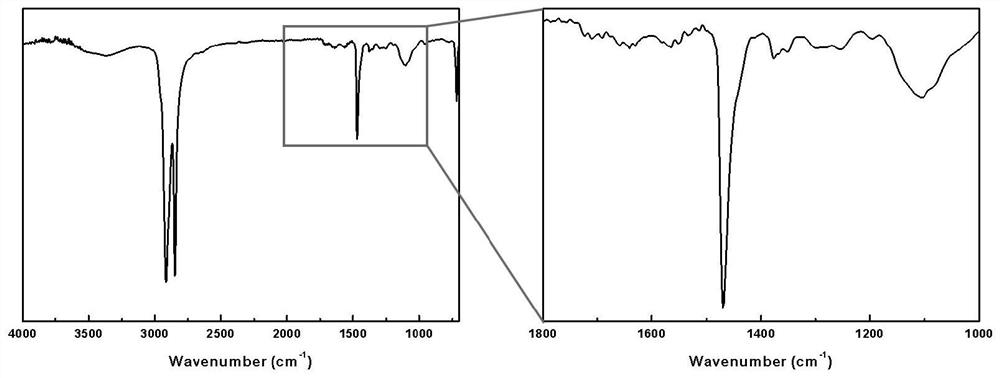

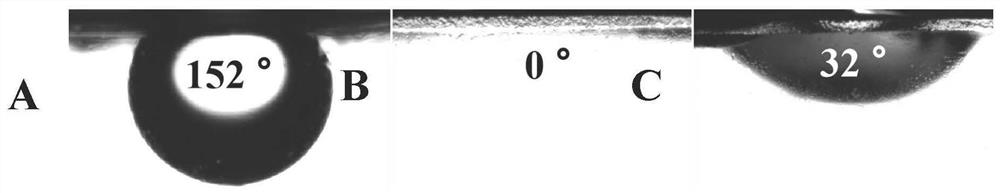

[0030] PEG-(SiR 2 O) 3 Diluted with water to a solid content of 5%, hydrolyzed by a magnetic stirrer at a pH of 4 to 5 for 2 hours, and then immersed the plasma-treated HDPE in the hydrolyzed PEG-(SiR 2 O) 3 For 1 h, put the treated HDPE into an oven at 120 °C for 30 min, rinse with plenty of water to remove free PEG-(SiR on the surface) 2 O) 3 to HDPE with anti-wax deposition (infrared spectrum of the sample surface as shown in figure 2 As shown, the underwater...

Embodiment 2

[0033] Others are the same as in Example 1, change PEG-(SiR 2 O) 3 The solid content of , the relationship between the solid content and the contact angle of the final product is as follows Figure 5 shown.

Embodiment 3

[0035] The HDPE surface is plasma treated, and the contact angle before and after wax deposition is as follows Figure 4 As shown, the contact angle of the underwater oil droplet is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com