Manufacturing method, steel wire and steel wire rope with alloy coating

A technology of alloy coating and manufacturing method, applied in the field of steel wire and steel wire rope, can solve the problems of reducing the fatigue resistance of steel wire rope, affecting the performance of customers, affecting production efficiency, etc., and achieves strong mechanical fixation, improved fatigue resistance, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

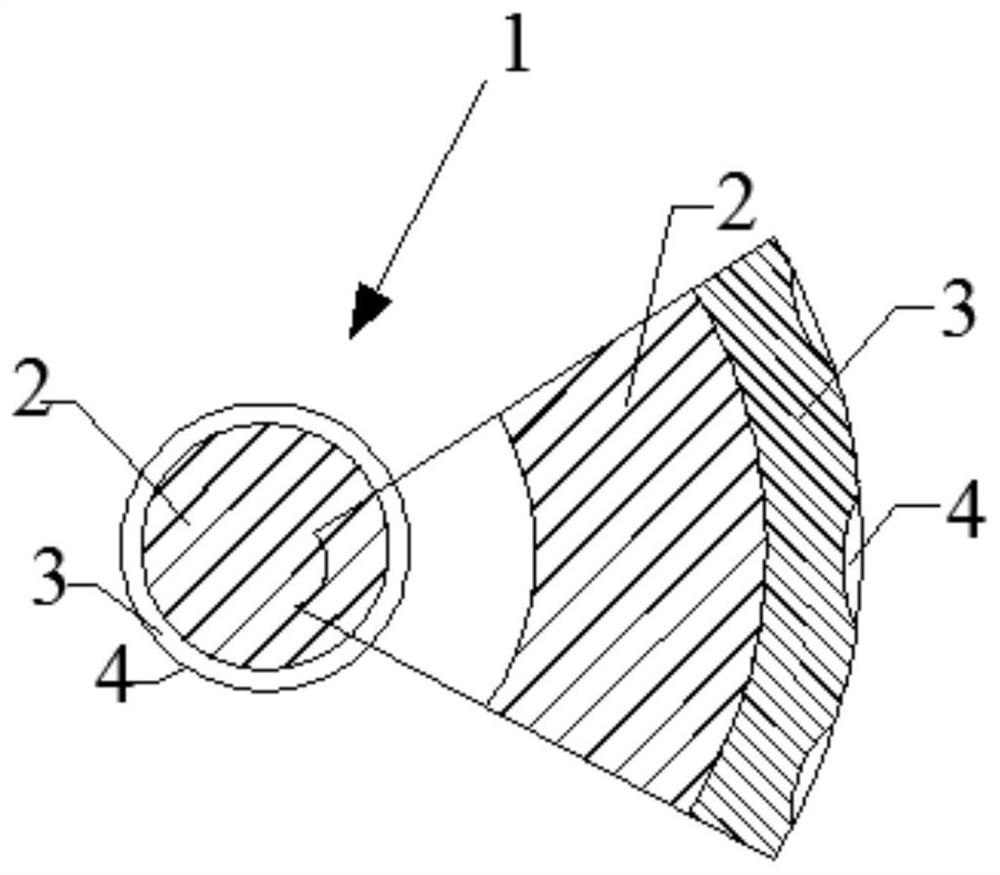

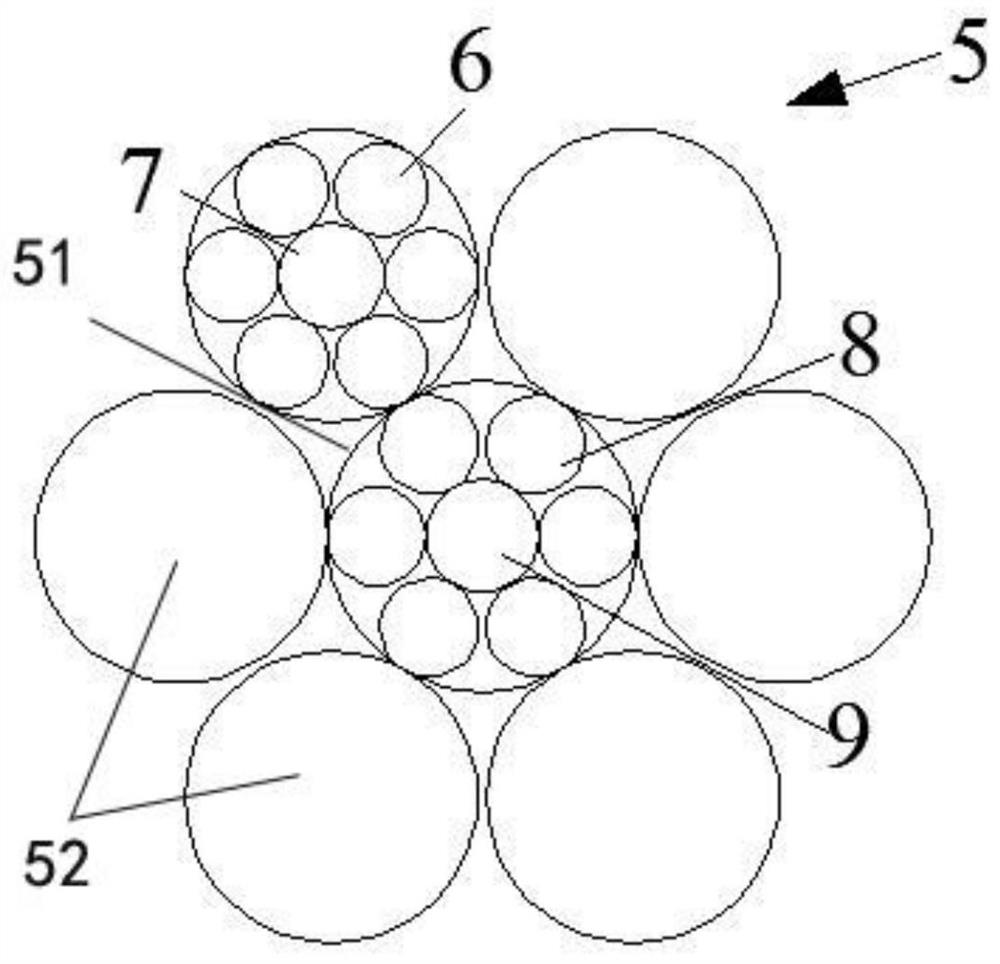

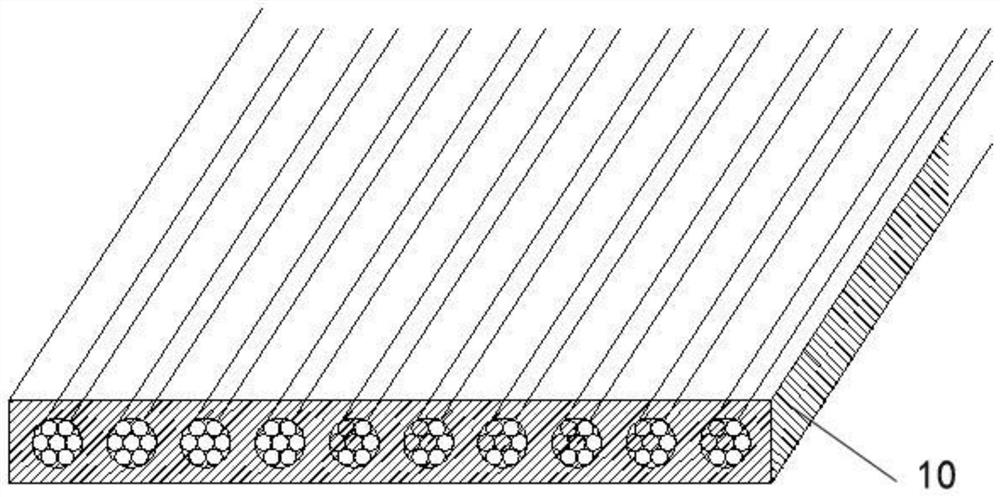

[0016] Such as Figure 1 to Figure 3 As shown, a manufacturing method of a steel wire with an alloy coating comprises the following steps: step a, cold drawing the wire rod to a required diameter, and then undergoing one or more appropriate heat treatments to facilitate subsequent drawing Pull out; step b, pass the steel wire substrate 2 obtained in step a through the zinc pot with molten zinc liquid, so that zinc is plated on the steel wire substrate 2, and the steel wire substrate 2 after galvanizing is at a certain angle with the horizontal line after exiting the zinc pot , through mechanical wiping, most of the pure zinc layer on the outermost layer of the steel wire substrate will be wiped off, and a steel wire substrate with an iron-zinc all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com