Novel gear selecting and shifting sensor structure

A sensor and gear selection technology, which is applied in the field of new gear selection sensor structure, can solve the problems of high installation and manufacturing costs, affect production tact, and reduce product life, and achieve reliable functions, increase production tact, and increase product life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

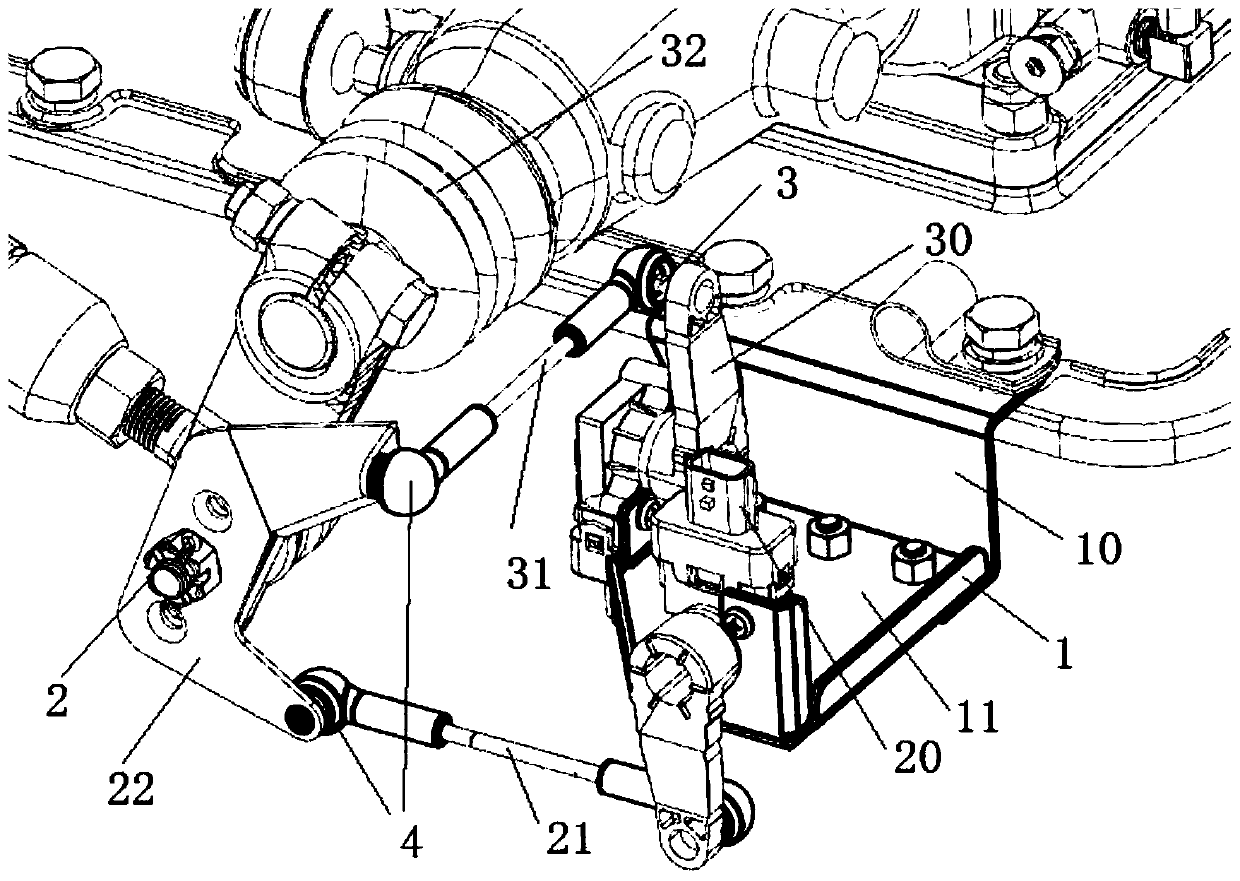

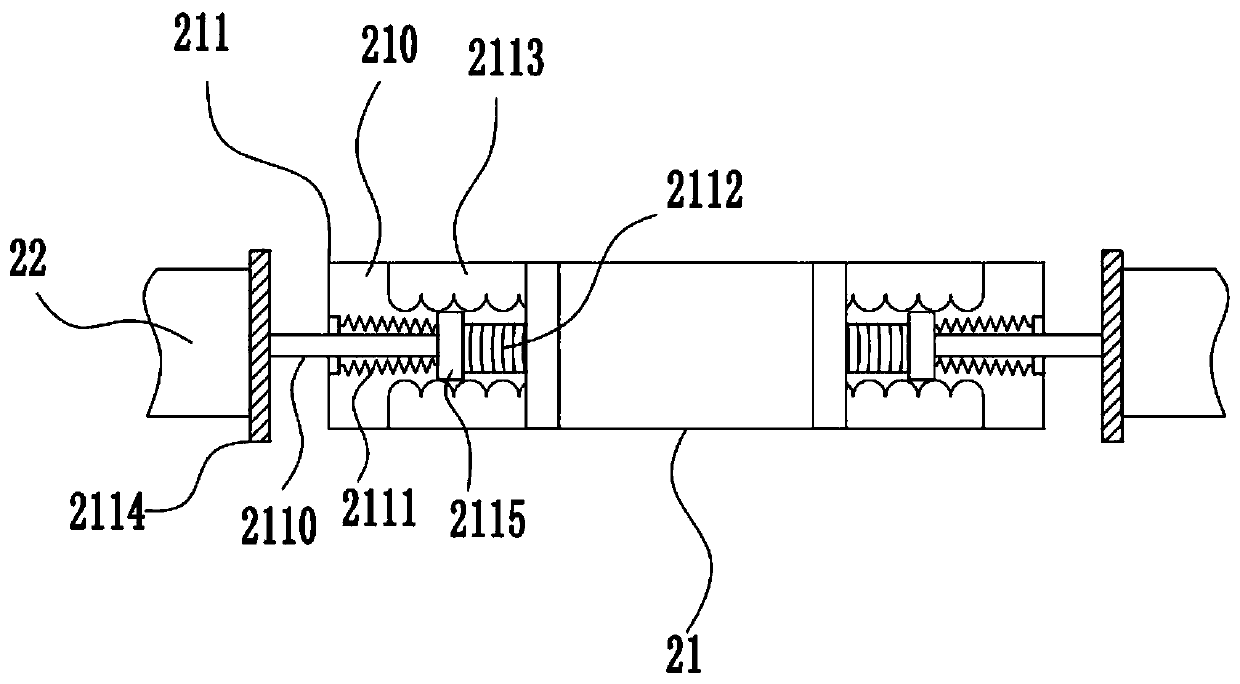

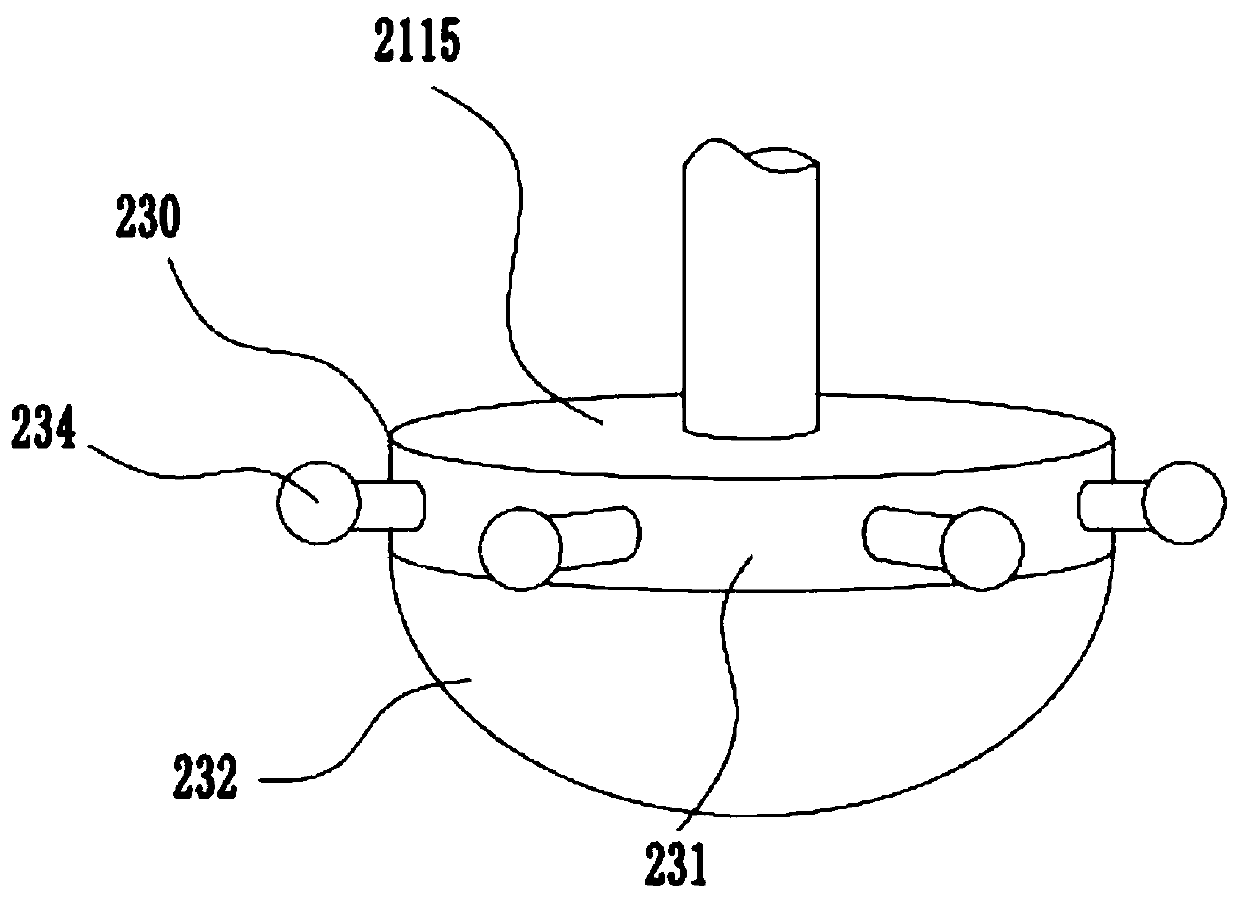

[0027] Such as figure 1 As shown, a novel shift sensor structure mainly includes a connecting bracket 1, a gear selection mechanism 2, a shifting mechanism 3, and a ball head mechanism 4. The connecting bracket 1 includes a fixed bracket 10, a mounting bracket 11, and the fixed bracket 10 is connected to the The main body is connected by a nut, and the mounting bracket 11 is connected with the connecting bracket 1; the gear selection mechanism 2 includes a gear selection sensor 20, a gear selection connecting rod 21, and a gear selection rocker arm 22, and the gear selection sensor 20 is arranged on the mounting bracket 11, and the gear selection The sensor 20 is connected with the external electronic control unit, one end of the gear selection connecting rod 21 is connected with the automobile gear shift cable, and the other end is connected with the gear selection rocker arm 22, as figure 2 As shown, the first buffer cavity 210 and the first buffer mechanism 211 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com