Lifting and translation motor mounting platform

A technology of installing a platform and a translation motor, which is applied in the directions of measuring devices, measuring electrical variables, measuring device casings, etc., can solve the problems of uneven tension of tie-rod bolts, low installation accuracy, and high risk, so as to improve test accuracy and reliability. , The effect of good lifting synchronization and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

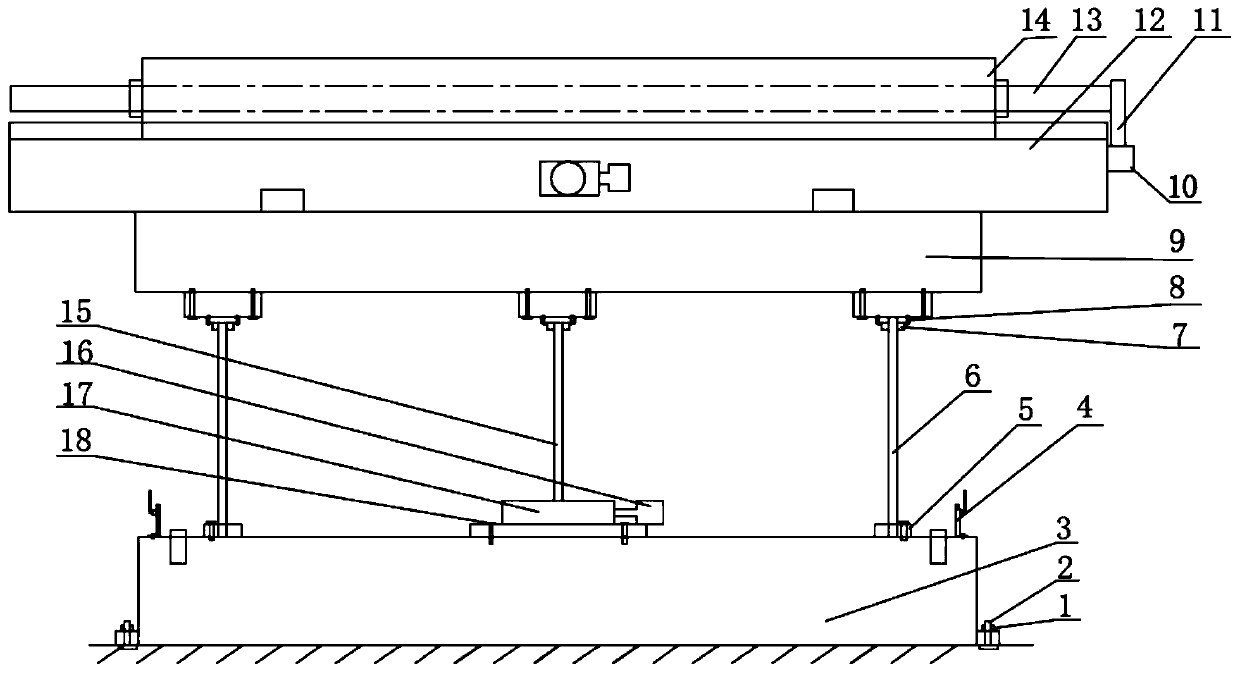

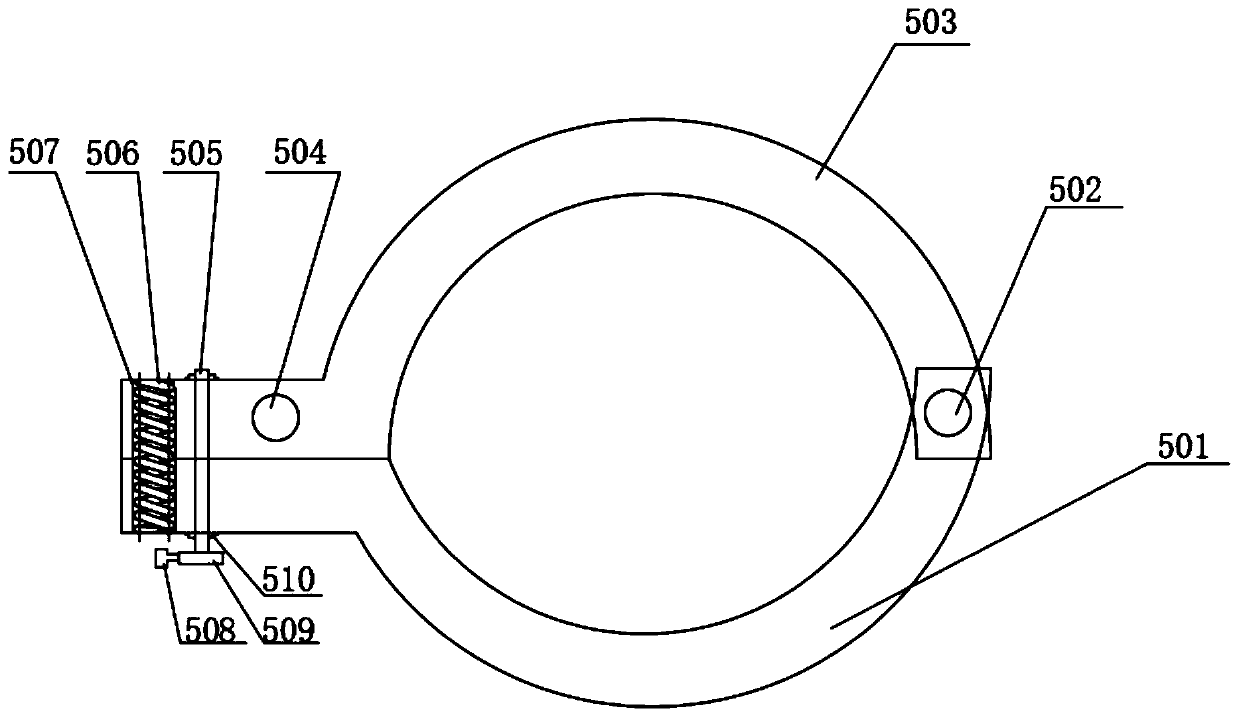

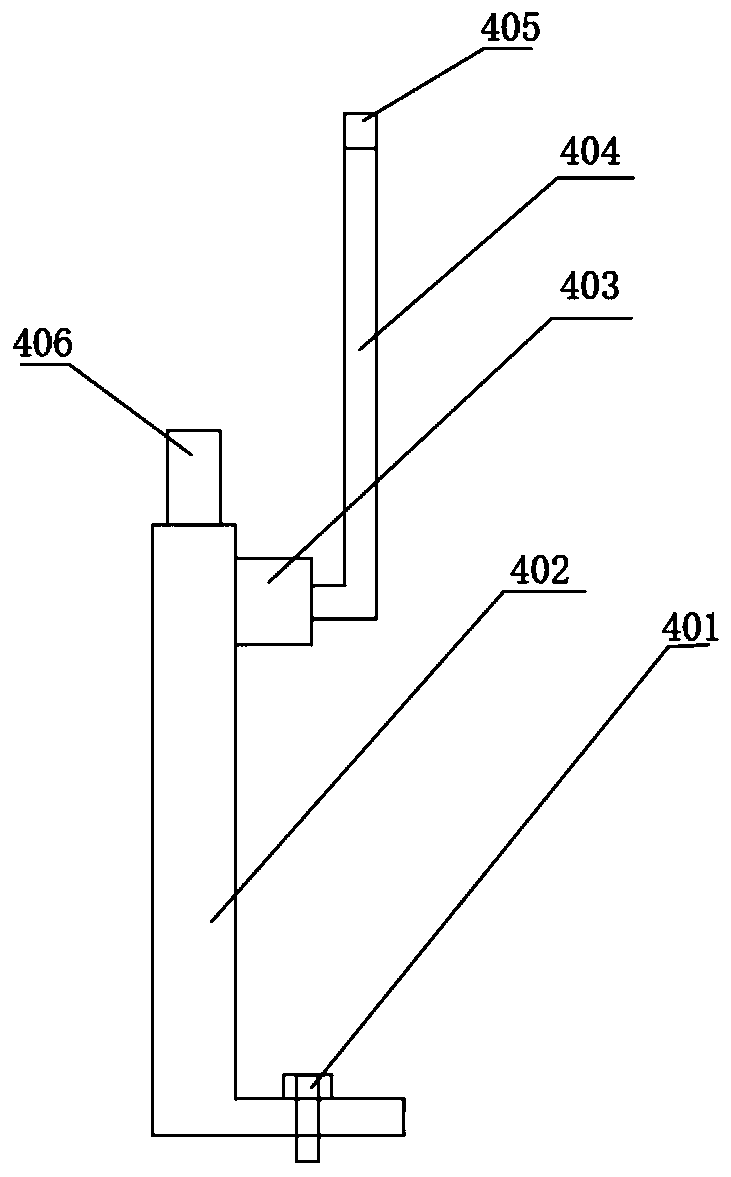

[0037] Such as figure 1 , Figure 4-Figure 5As shown, the lifting translation motor installation platform of this embodiment includes a fixedly installed support base 3, the middle part of the upper surface of the support base 3 is connected to the lower table 9 through a power transmission mechanism, and a limit mechanism is installed on both sides of the upper surface of the support base 3 4. The upper surface of the lower table 9 is slidingly installed with a middle table 12, and the upper surface of the middle table 12 is installed with an upper table 14 perpendicular to its movement direction. It is connected with one end of a screw rod 13, and the screw rod 13 is penetrated in the upper table 14; the bottom of the lower table 9 is equipped with a guide rod 6, and the support base 3 is provided with a guide hole 308 for the guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com