Projection device for visual communication design

A projection device and visual technology, applied in projection devices, photography, mechanical equipment, etc., can solve the problems of inconvenient maintenance, bulky, inconvenient movement, etc., and achieve the effect of improving product characteristics, increasing projection area, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

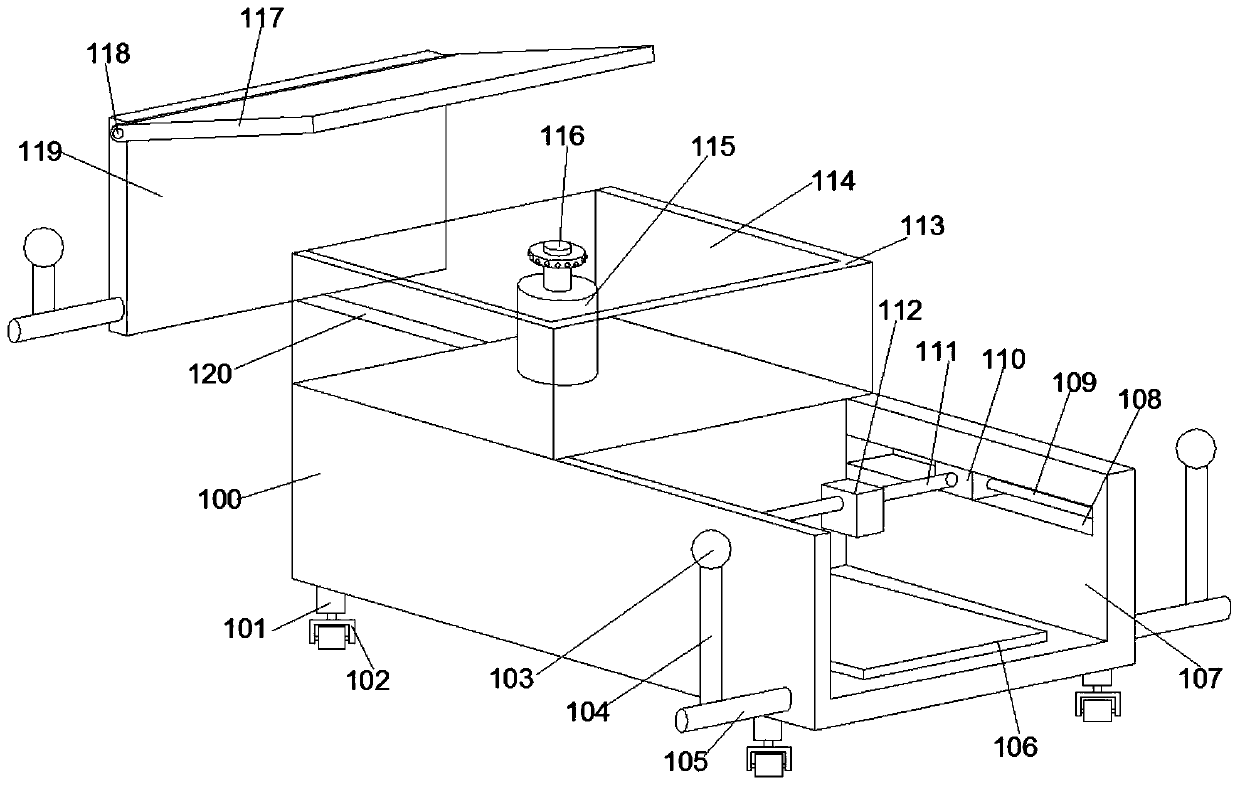

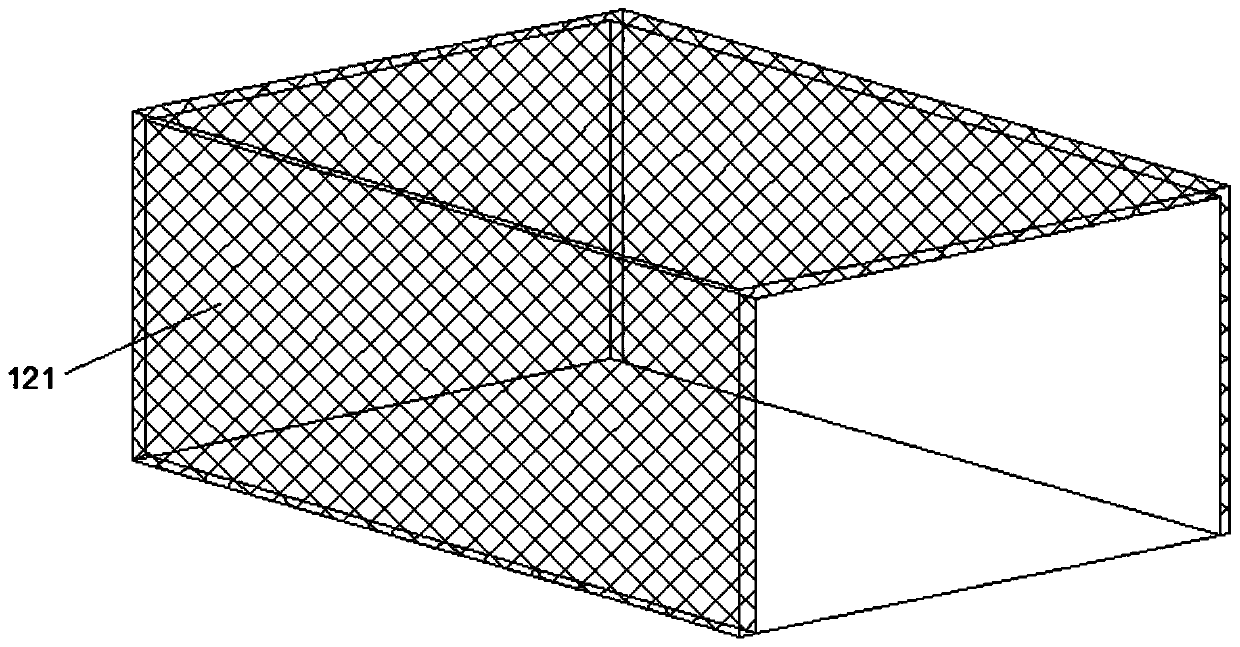

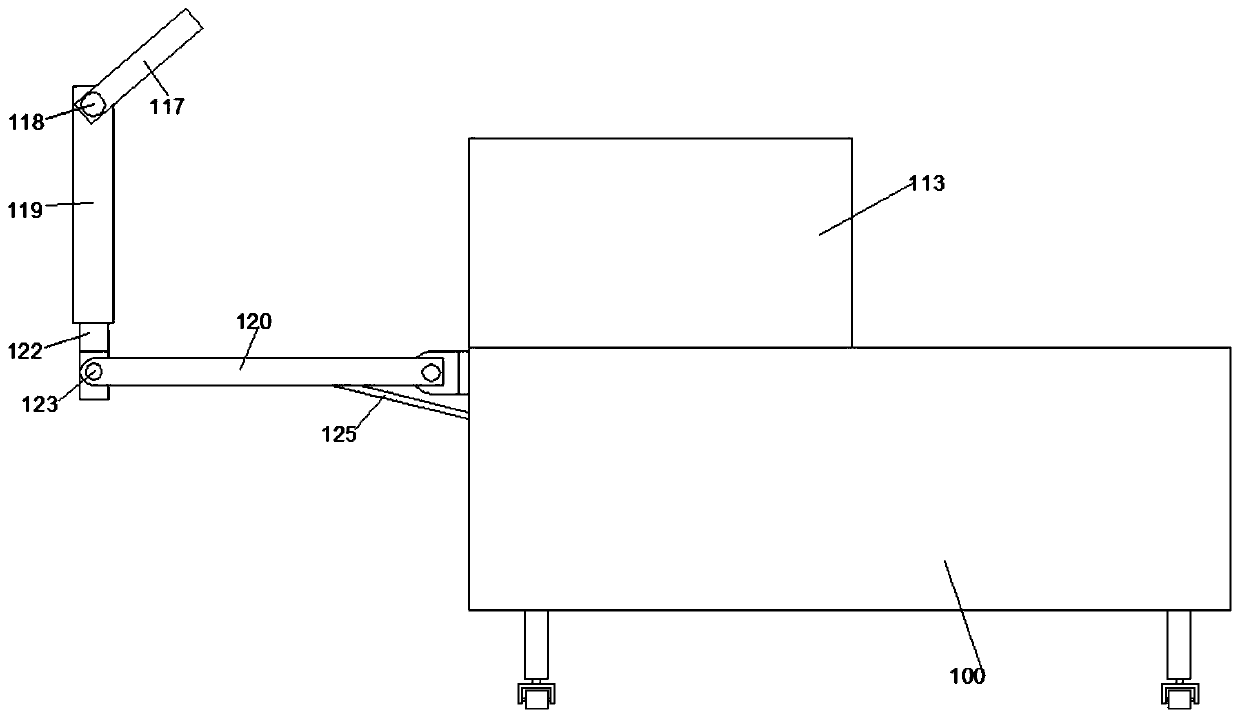

[0029] see Figure 1-6, a projection device for visual communication design, which includes a car body 100, the top of the car body 100 is provided with a projection device, wherein the projection device includes a protective box 113 for protection, a projector 115, and an assembly for the same structure. A movable plate mechanism that can be used to seal the protection box 113 and projection imaging; a multi-angle shooting cavity 107 located on the other side of the protection box 113 is excavated in the car body 100, and a visual symbol display table 106 is provided at the bottom of the multi-angle shooting cavity 107. The visual symbol display stand 106 is provided with LED lights, and the multi-angle shooting cavity 107 is provided with a planar camera displacement drive mechanism. The projection device also includes a flexible light-shielding tent support frame that is arranged on the outer side of the vehicle body 100 on the side of the multi-angle shooting cavity 107. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com