Power fault monitoring system and method

A power failure and monitoring system technology, applied in the direction of circuit devices, electrical components, etc., can solve the problems of high degree of automation and intelligence, single structure and function, and achieve the effect of high degree of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

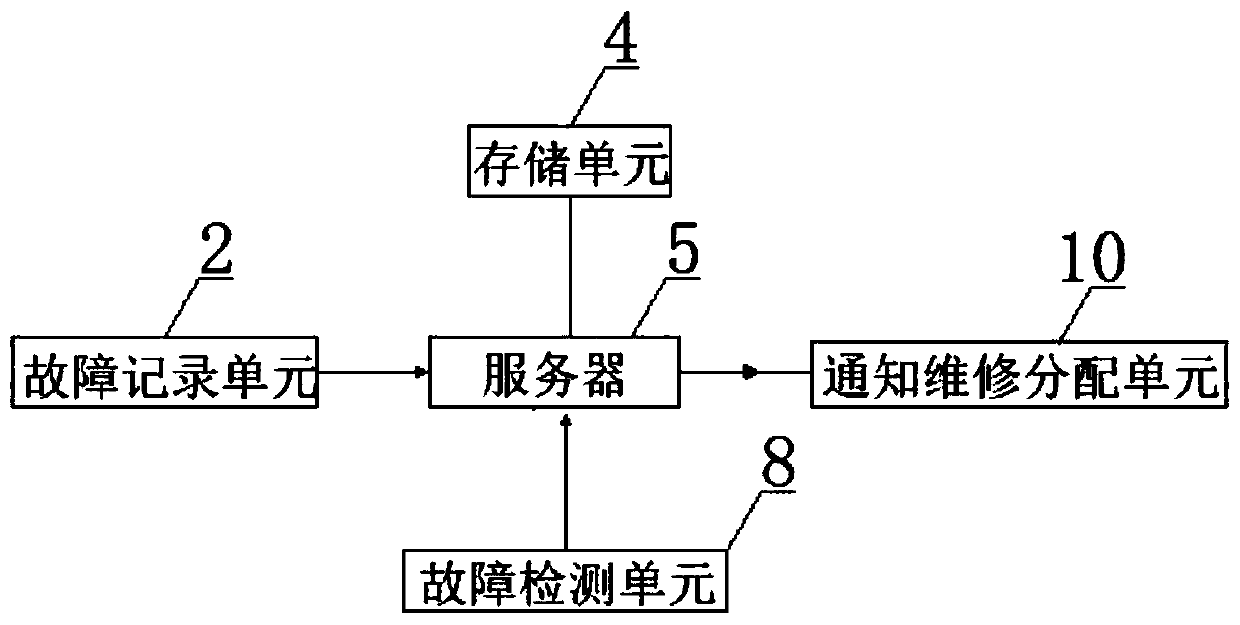

[0041] Such as figure 1 As shown, in this embodiment, a power failure monitoring system for a steel company includes a server 5, a failure detection unit 8, a notification maintenance distribution unit 10, a failure recording unit 2, a storage unit 4; the failure detection unit 8. The server 5 is communicatively connected to the server 5 for monitoring fault information, and the fault information is transmitted to the server 5 for fault analysis; the server 5 is communicatively connected to the notification maintenance distribution unit 10 for fault analysis The analysis result is sent to the notification maintenance distribution unit 10; the notification maintenance distribution unit 10 is used to allocate maintenance personnel to perform maintenance inspections according to the failure analysis results; the failure recording unit 2 is communicatively connected to the server 5 for use To record the fault information and the fault analysis result; the storage unit 4 is communica...

Embodiment 2

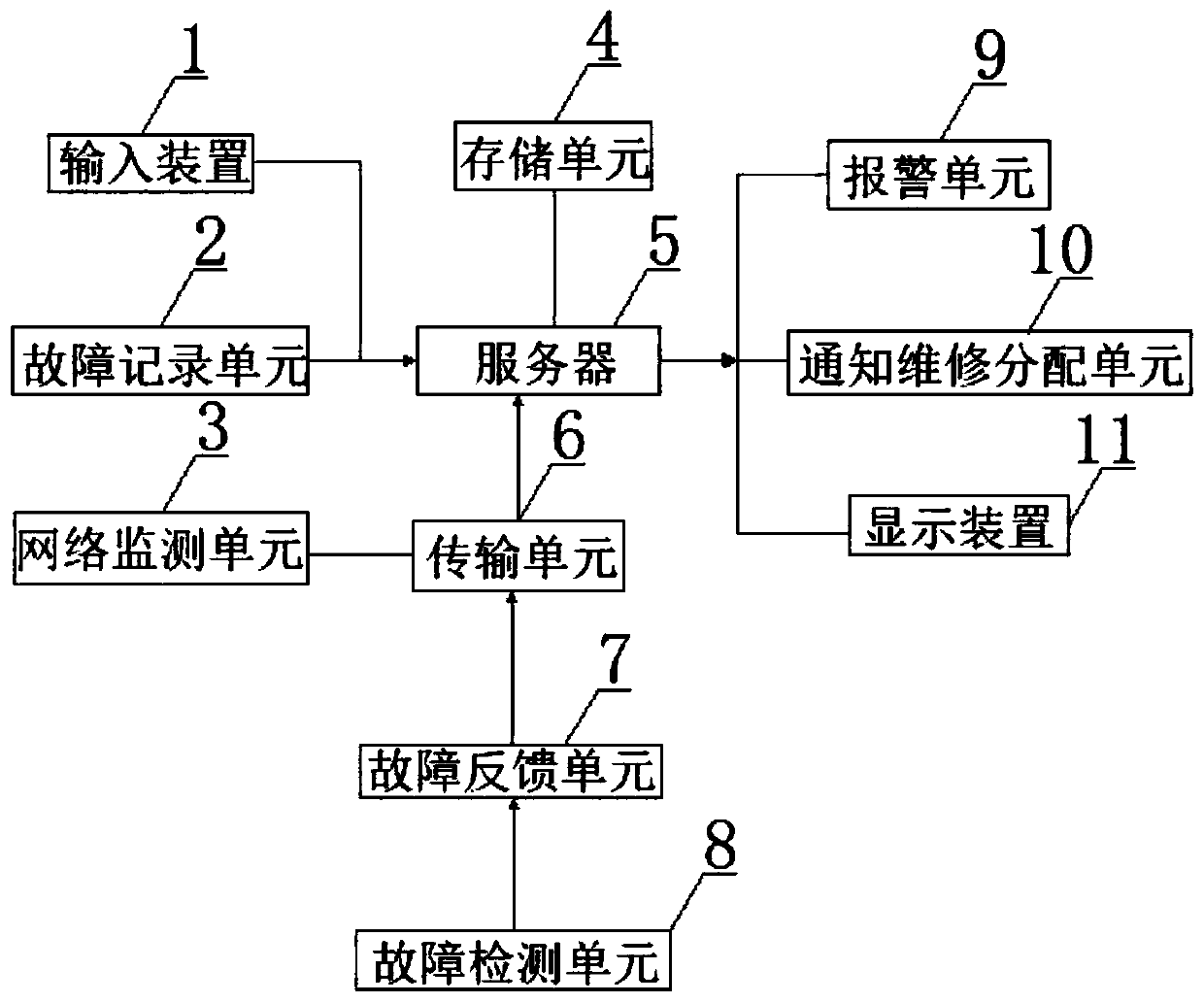

[0048] In this embodiment, on the basis of the first embodiment, the fault feedback unit 7 is also communicatively connected between the server 5 and the fault detection unit 8 for the working conditions of simultaneous monitoring of multiple points in the power system. It collects the monitoring data from multiple monitoring points, converts the monitoring data according to the transmission requirements, and then transmits it to the server 5.

Embodiment 3

[0050] In this embodiment, on the basis of the second embodiment, in order to monitor abnormalities in the data transmission process, the fault feedback unit 7 and the server 5 are connected through a transmission unit 6, and the transmission unit 6 is communicatively connected with a network monitoring unit.

[0051] Specifically, in this embodiment, the network monitoring unit 3 may be an existing network monitoring device or system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com