Pulling type radish harvesting robot

A technology of robots and radishes, applied in the direction of digging harvesters, harvesters, manipulators, etc., can solve problems such as the inability of machinery to harvest efficiently, and achieve the effects of improving extraction ability, reducing energy consumption, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The above is the content of the technical solution of the present invention, and now the solution of the present invention is described in detail as follows:

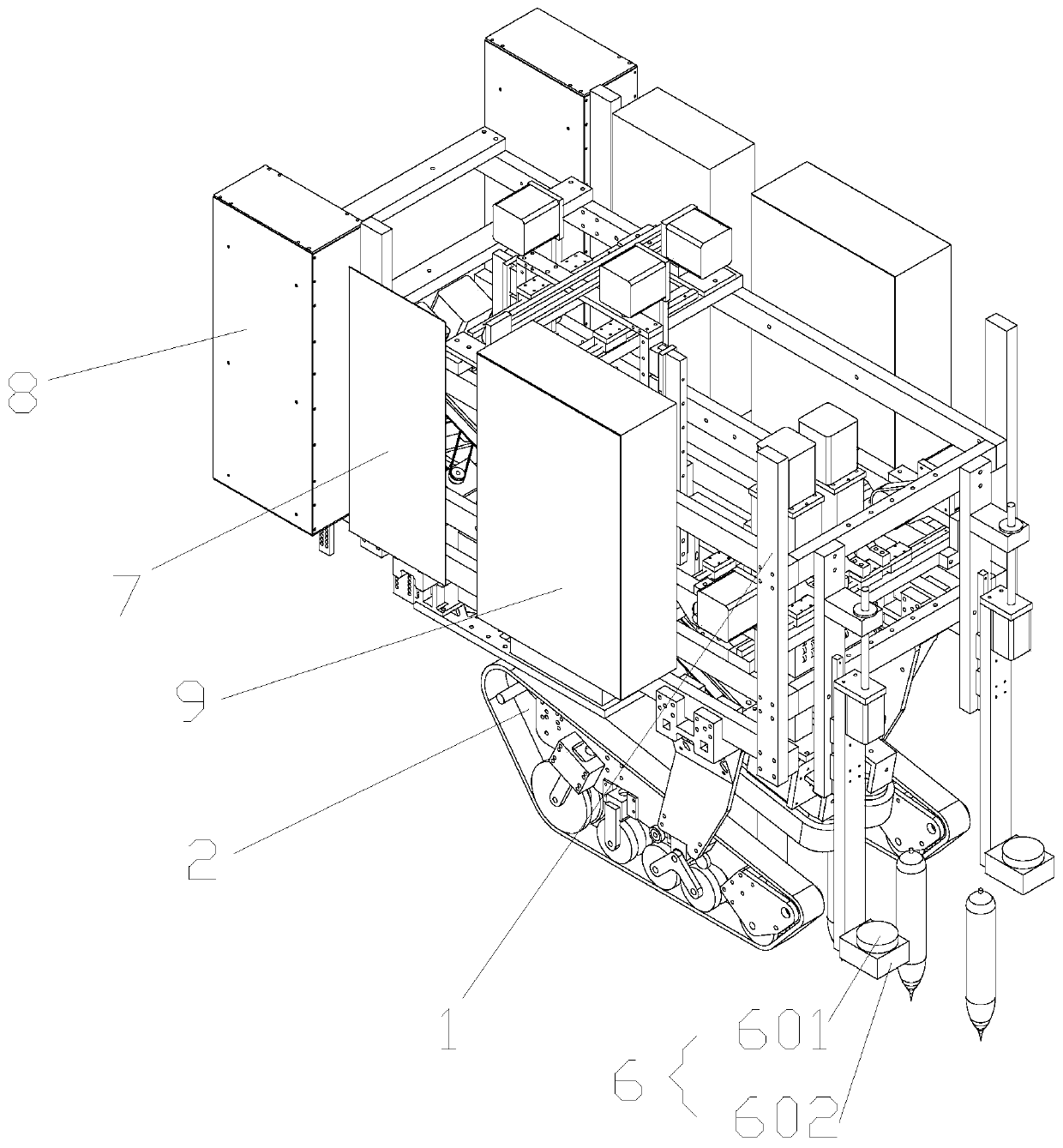

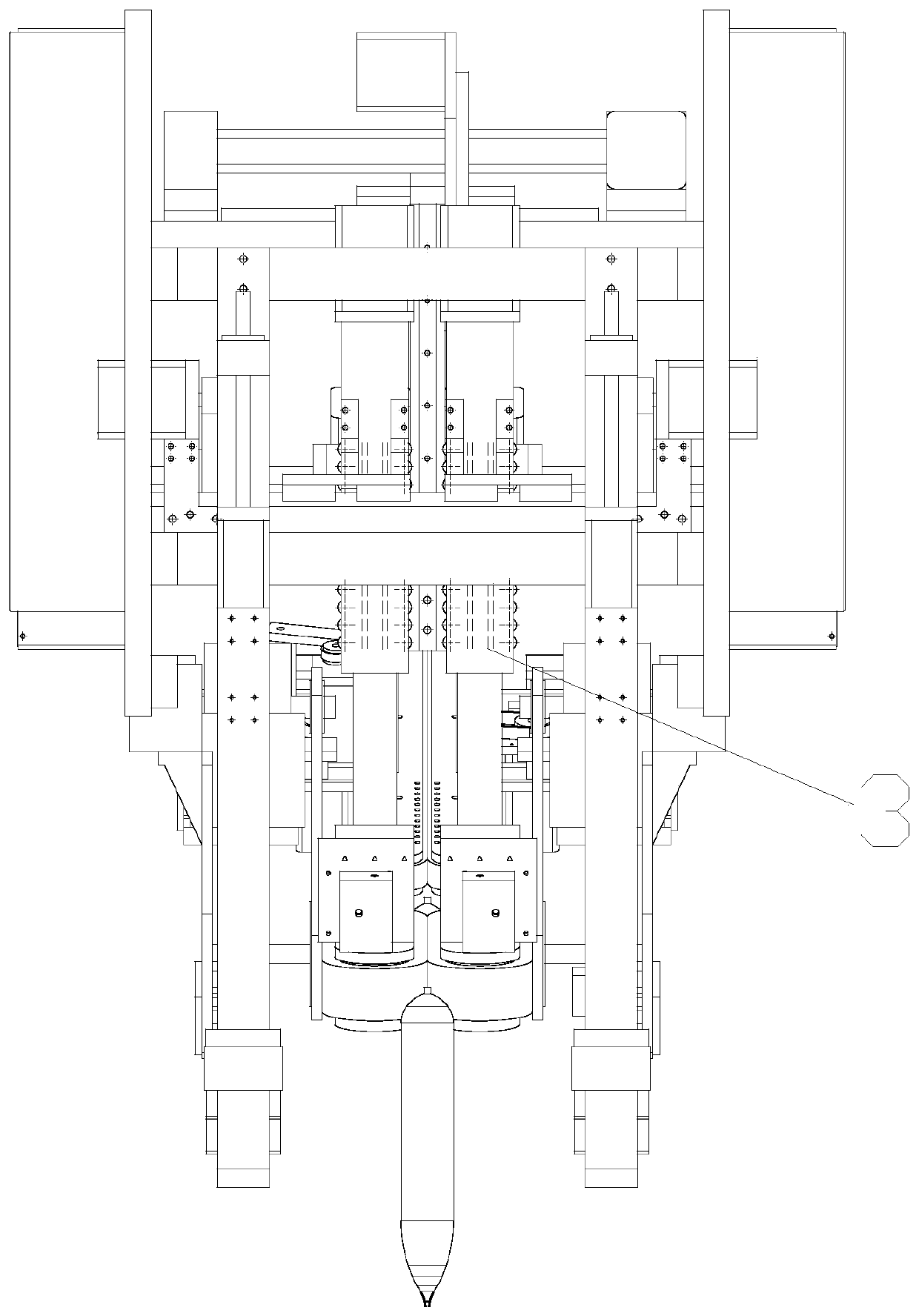

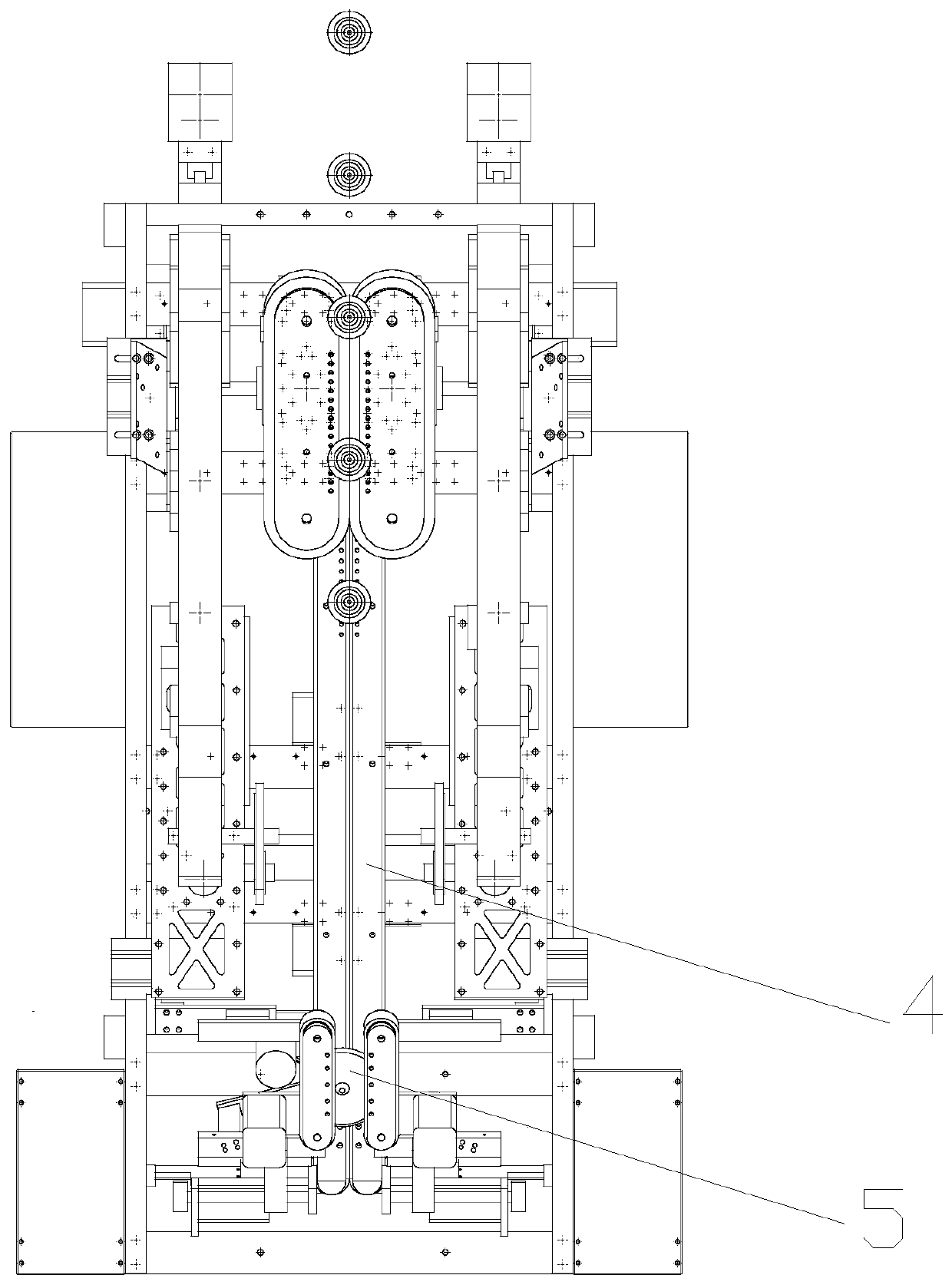

[0043] refer to Figure 1~Figure 16 , the embodiment discloses a pull-out radish harvesting robot, including a main frame 1 and a walking mechanism 2 connected to the main frame 1, a pulling mechanism 3, a transmission mechanism 4, a leaf cutting mechanism 5, a sensing mechanism 6, a driving mechanism 7, The control mechanism 8 and the battery box 9, the walking mechanism 2 is arranged at the lower end of the main frame 1 to support the walking of the robot, the extracting mechanism 3 is arranged at the front end of the main frame 1 and is adjacent to the transmission mechanism 4, and the transmission mechanism 4 is arranged in the main frame 1, and the transmission mechanism 4 is arranged inclined from bottom to top, the leaf cutting mechanism 5 is arranged at the rear end of the transmission mechanism 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com