Kitchen waste solid-liquid extrusion and spin-dry separation device

A kitchen waste and separation device technology, which is applied in the direction of presses, solid waste removal, manufacturing tools, etc., can solve the problems of low efficiency and inability to deal with solid waste, and achieve the effect of high drying efficiency and fast rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

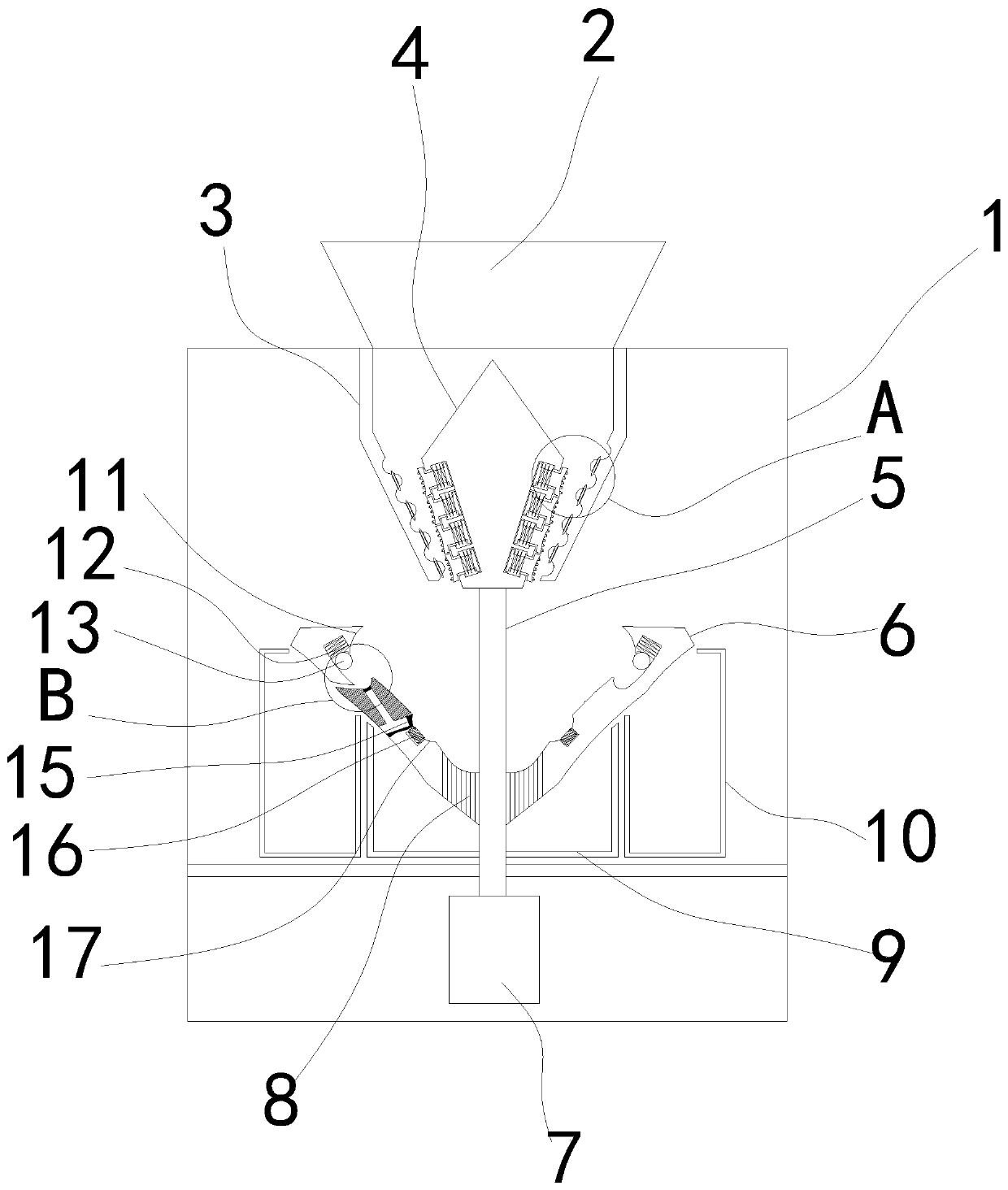

[0027] see Figures 1 to 7 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of a kitchen waste solid-liquid extrusion drying separation device.

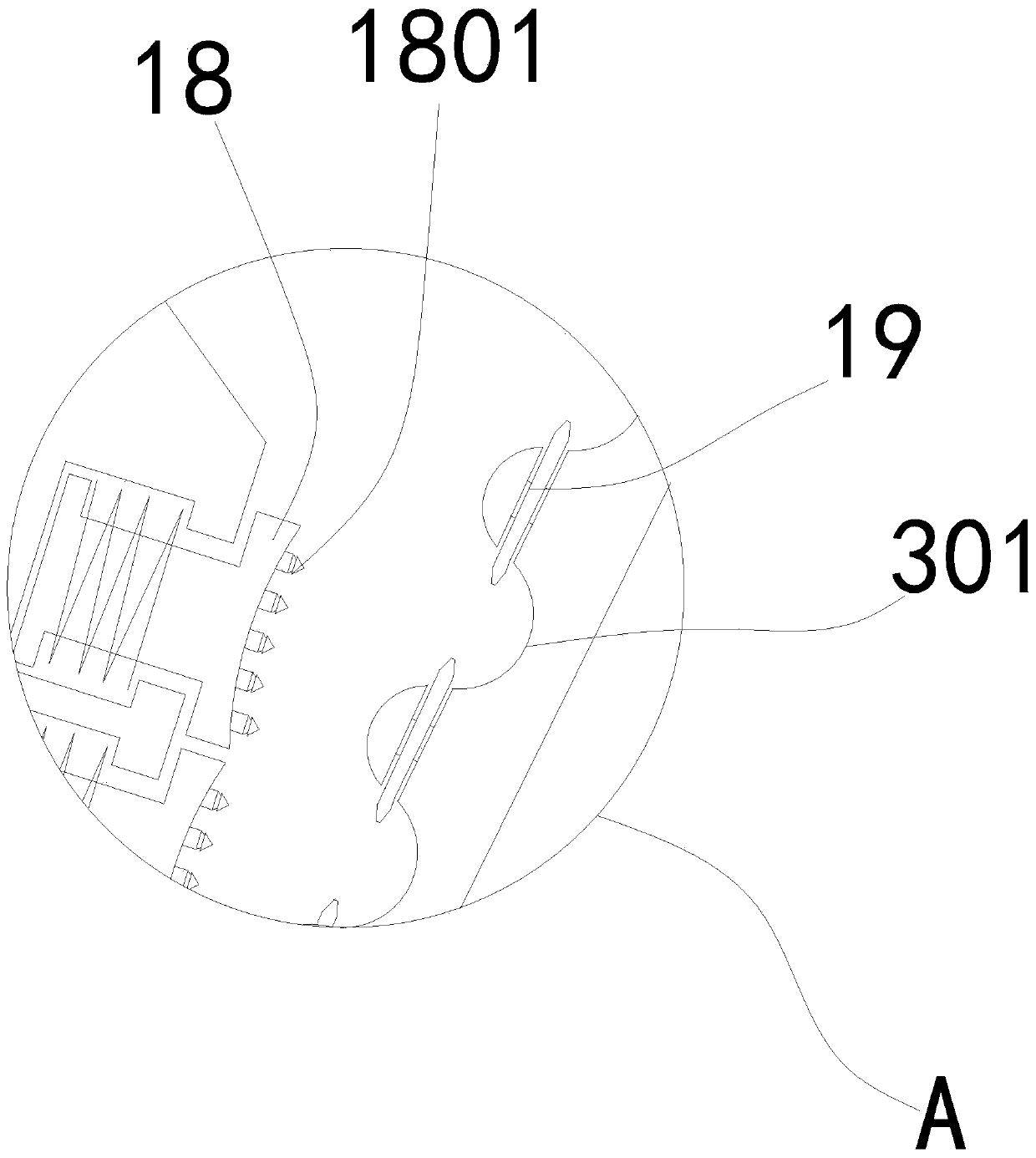

[0028] A solid-liquid extrusion, drying and separation device for kitchen waste, comprising a device main body 1, a material inlet 2, the lower end of the material inlet 2 is fixedly connected with an extrusion chamber 3, and the inner wall of the extrusion chamber 3 is provided with a groove 301 for extrusion. A crushing runner 19 is movably installed on the inner wall of the chamber 3, an extruding cone 4 is movably installed in the center of the extruding chamber 3, and an extruding block 18 is movably installed on the extruding cone 4, and the outer surface of the extruding block 18 is fixedly connected with a fixed protrusion. Block 1801, the inside of the broken runner 19 is fixedly equipped with an oblique block 21, and the inside of the broken runner 19 is movable with a broken ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com