Three-station polishing machinery based on mechanical grinding

A mechanical grinding, three-station technology, used in grinding/polishing equipment, surface-polished machine tools, grinding/polishing safety devices, etc. shavings and other problems, to achieve the effect of convenient and rapid cleaning, safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

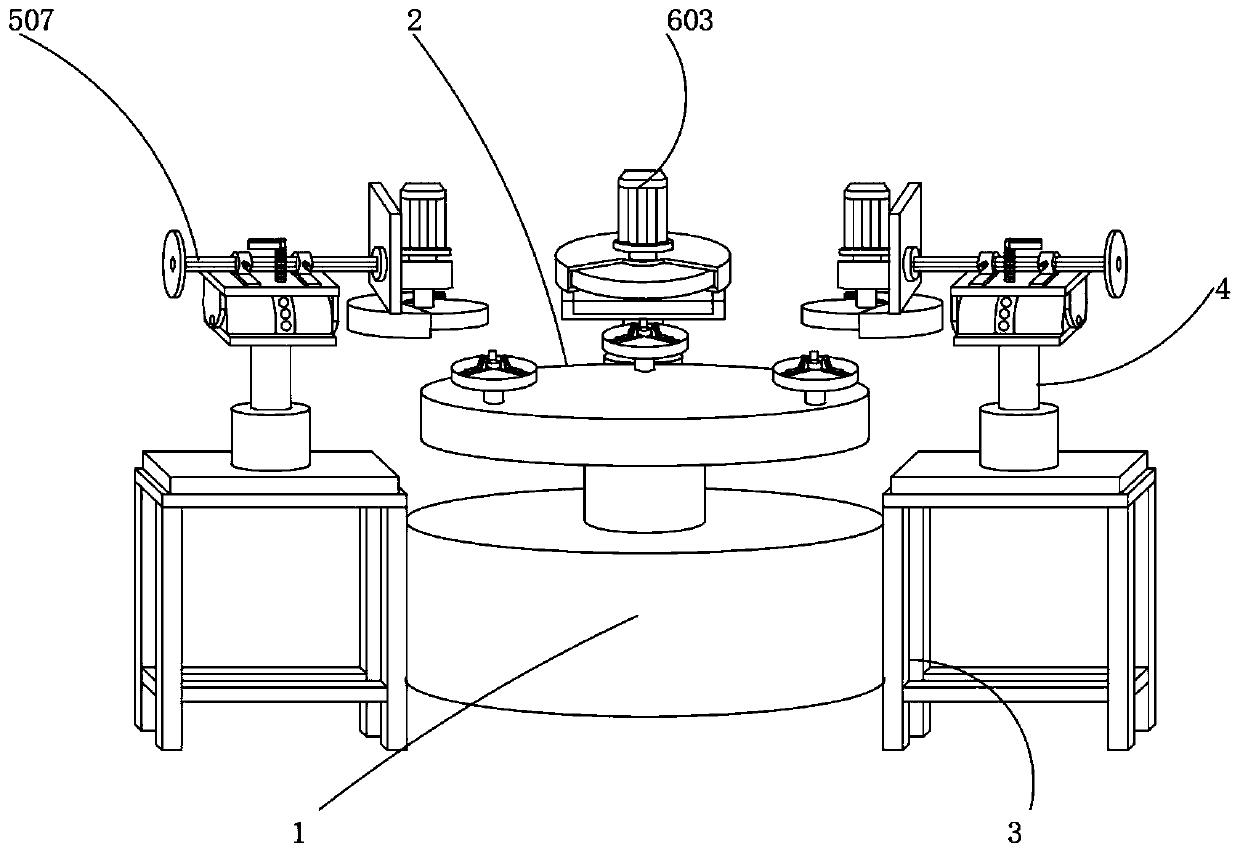

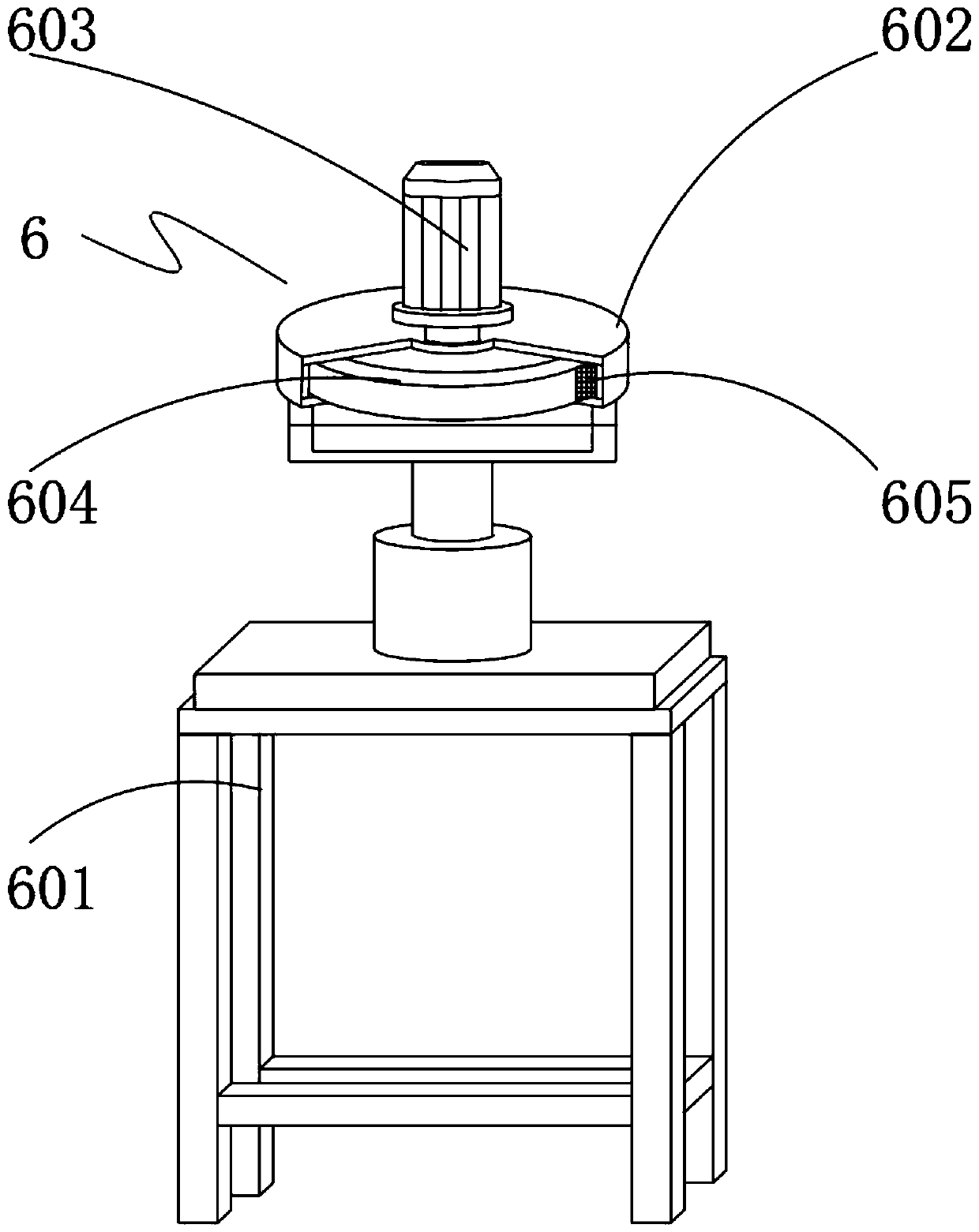

[0027] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a three-station polishing machine based on mechanical grinding, including a polishing machine body 1, a turntable 2 is installed on the top of the polishing machine body 1, and first Mounting frame 3, a hydraulic cylinder 4 is installed on the top of the first mounting frame 3.

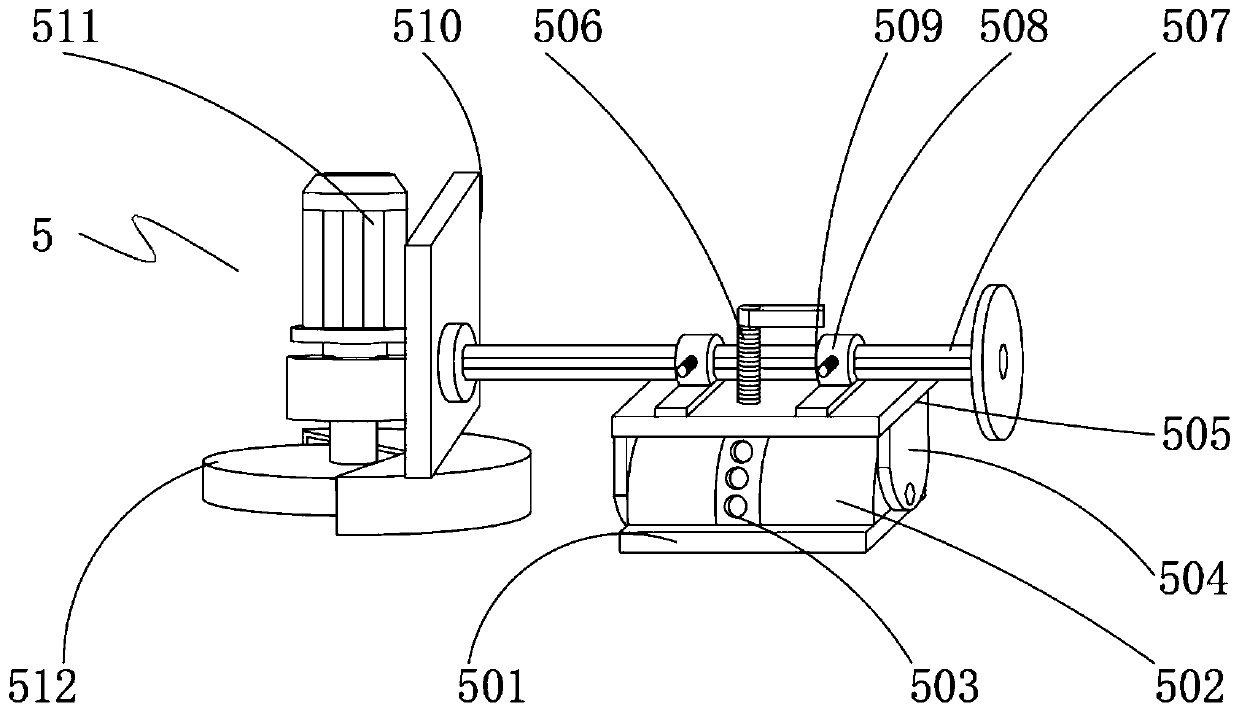

[0028] The top of the hydraulic cylinder 4 is provided with a polishing assembly 5, which includes a mounting plate 501, a support block 502, a positioning groove 503, a positioning plate 504, a movable plate 505, a positioning screw 506, a connecting rod 507, a positioning sleeve 508, and a positioning screw 509 , a baffle plate 510, a first drive motor 511 and a polishing wheel 512.

[0029] The mounting plate 501 is fixedly mounted on the top of the hydraulic cylinder 4, the middle part of the top surface of the mounting plate 501 is fixedly equipped with a support block 502, and the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com