Surface derusting device of packaging steel band

A technology for steel belts and cloth belts, which is applied to grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult cleaning, enterprise losses, and waste of steel belts, so as to reduce processing difficulty and processing costs. The effect of low precision requirements and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

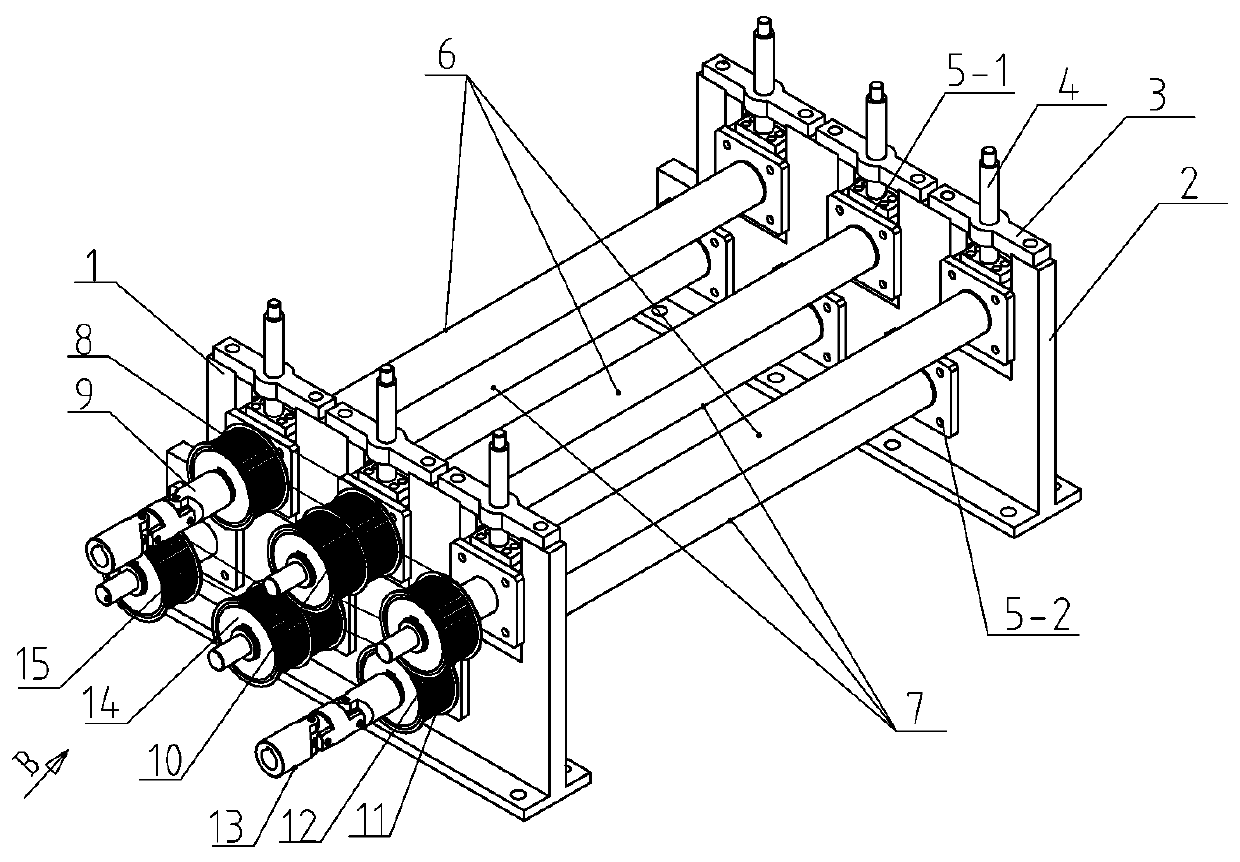

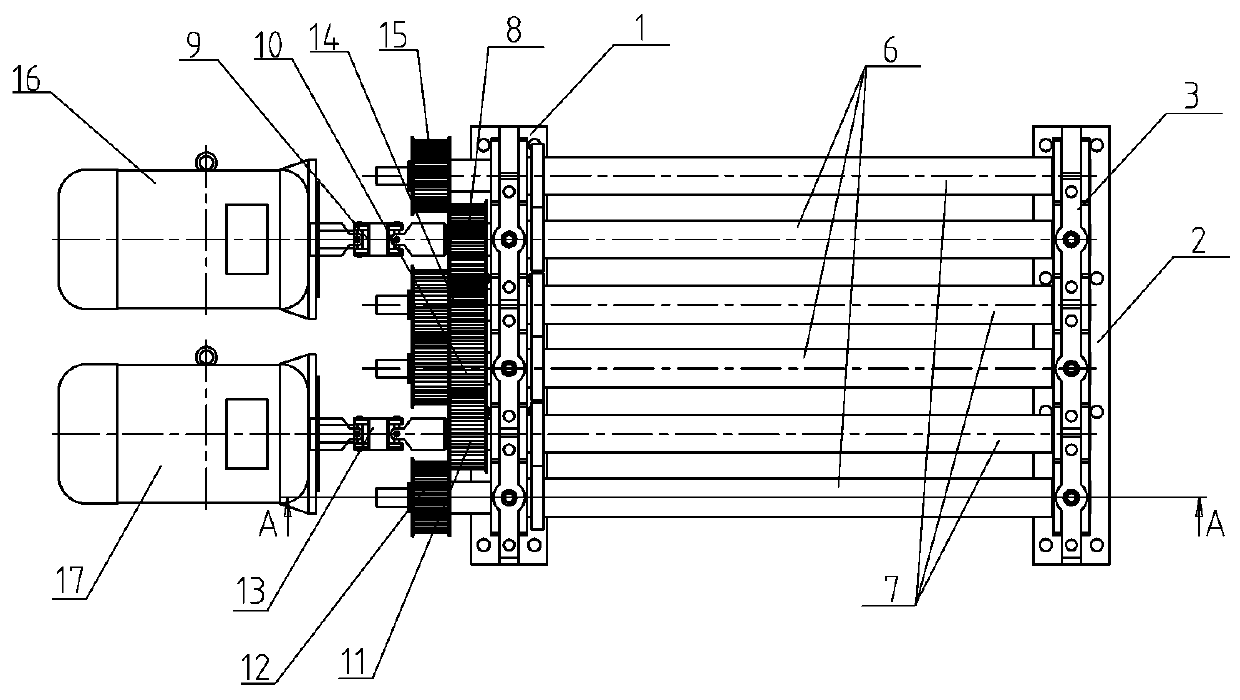

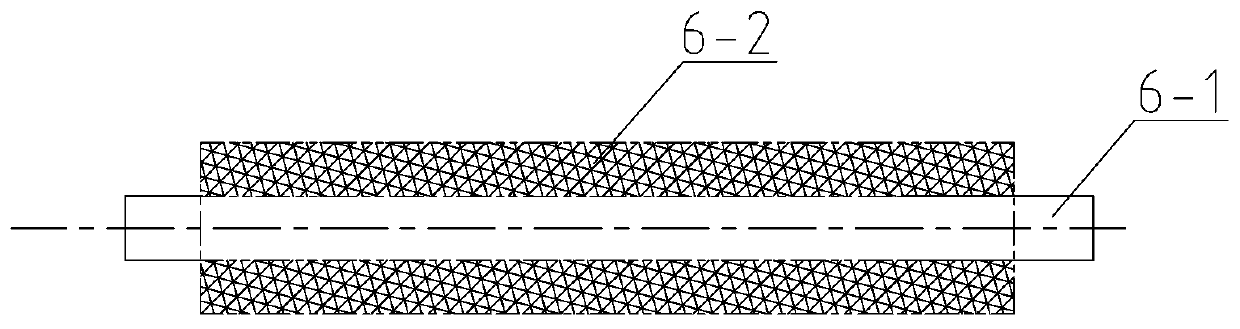

[0024] Such as Figure 1-Figure 5 As shown, a kind of packaging steel strip surface derusting device of the present invention is characterized in that, described packaging steel strip surface derusting device comprises frame, belt pulley mechanism and belt pulley driving mechanism, and described belt pulley The mechanism is composed of upper cloth pulley group 6 and lower cloth pulley group 7 respectively,

[0025] The frame is composed of a front archway frame 1 and a rear archway frame 2 fixedly installed on the steel base between the uncoiler of the galvanized steel strip production line and the pickling tank. More than three grooves are evenly and symmetrically opened, and each groove is provided with a movable bearing box 5-1 for installing the cloth pulley shaft of the upper cloth pulley group, and the lower part of the front arch frame and the rear arch frame are mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com