Auxiliary thumbnail and piston ring removal and installation tool

A thumb and nail technology, applied in the field of auxiliary thumb nails and piston ring disassembly and assembly tools, can solve the problems of thumb nail damage, separation of fingers, painful thumb nail pulling force, etc., to achieve the effect of improving efficiency and improving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

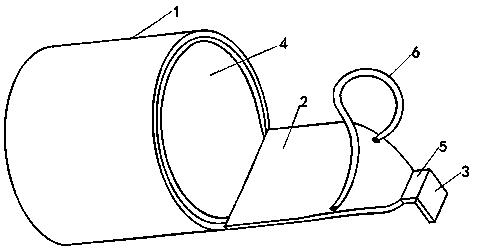

[0057] Such as figure 1 Shown is a schematic view of the structure of the auxiliary thumb nail in a preferred embodiment of the present invention. The auxiliary thumbnail of the present embodiment includes a thumb clamping surface 1, a force application surface 2 and a working surface 3, and lining materials 4 such as rubber, silica gel or cloth, fiber materials, etc. Positioning surfaces 5 are provided at both ends, and an elastic retaining belt 6 is provided on the force application surface 2 .

[0058] The thumb clamping surface 1 is a cylindrical surface with a length of 2.1 cm; the first end of the thumb clamping surface 1 is at the mouth of the tiger, and the second end of the thumb clamping surface 1 does not go beyond the first and second joints of the thumb joint; the inner diameter of the thumb clamping surface 1 is 2.6 centimeters. The thumb locking surface 1 is set on the thumb. When the thumb is bent, the center line of the thumb locking surface 1 deviates from ...

Embodiment 2

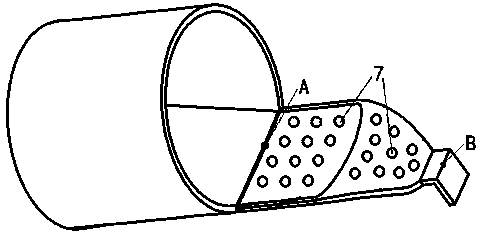

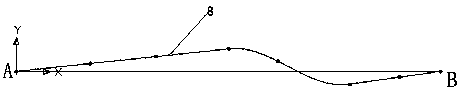

[0067] figure 2 It is a schematic diagram of the arrangement of anti-slip bosses on the force application surface of a preferred embodiment of the present invention. The anti-slip boss 7 in this embodiment is an anti-slip measure for the force-applying surface 2 to ensure the force applied by the thumb. The force application surface 2 is an important part of the force application by the thumb, which mainly relies on positive pressure and friction to generate pulling force. The anti-skid boss 7 is set on the force application surface 2 to prevent slippage between the thumb and the force application surface 2, increase the friction force, properly reduce the positive pressure, reduce the force of the two ends of the thumb clamping surface 1, and improve the stability of the working process. comfort. In addition, the anti-slip boss 7 can increase the roughness of the contact surface, thereby increasing the friction between the thumb and the force application surface 2 . Durin...

Embodiment 3

[0070] Figure 4 It is a schematic diagram of the bolt connection joint between the force application surface and the thumb clamping surface in a preferred embodiment of the present invention. The thumb clamping surface 1 and the force application surface 2 are manufactured separately, and are fixed into one body through a bolt connection joint 9 . The bolted joint 9 is a high-strength connection. Wherein, the thumb locking surface 1 and the force application surface 2 are made of different materials, the force application surface 2 is made of a material with higher rigidity, and the thumb locking surface 1 is made of a soft material. Adopting the bolt connection joint 9 can make the thumb locking surface 1 and the force application surface 2 be assembled and connected, which is convenient for manufacture and disassembly. It can not only ensure that the auxiliary thumb has greater rigidity and strength, avoid excessive deformation, but also make the thumb touch the soft mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com