Cement storing and taking device for laboratory

An access device and laboratory technology, which is applied in the direction of sampling device, mixer with rotating stirring device, packaging, etc., to achieve the effect of stable connection, simple operation and reduced dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

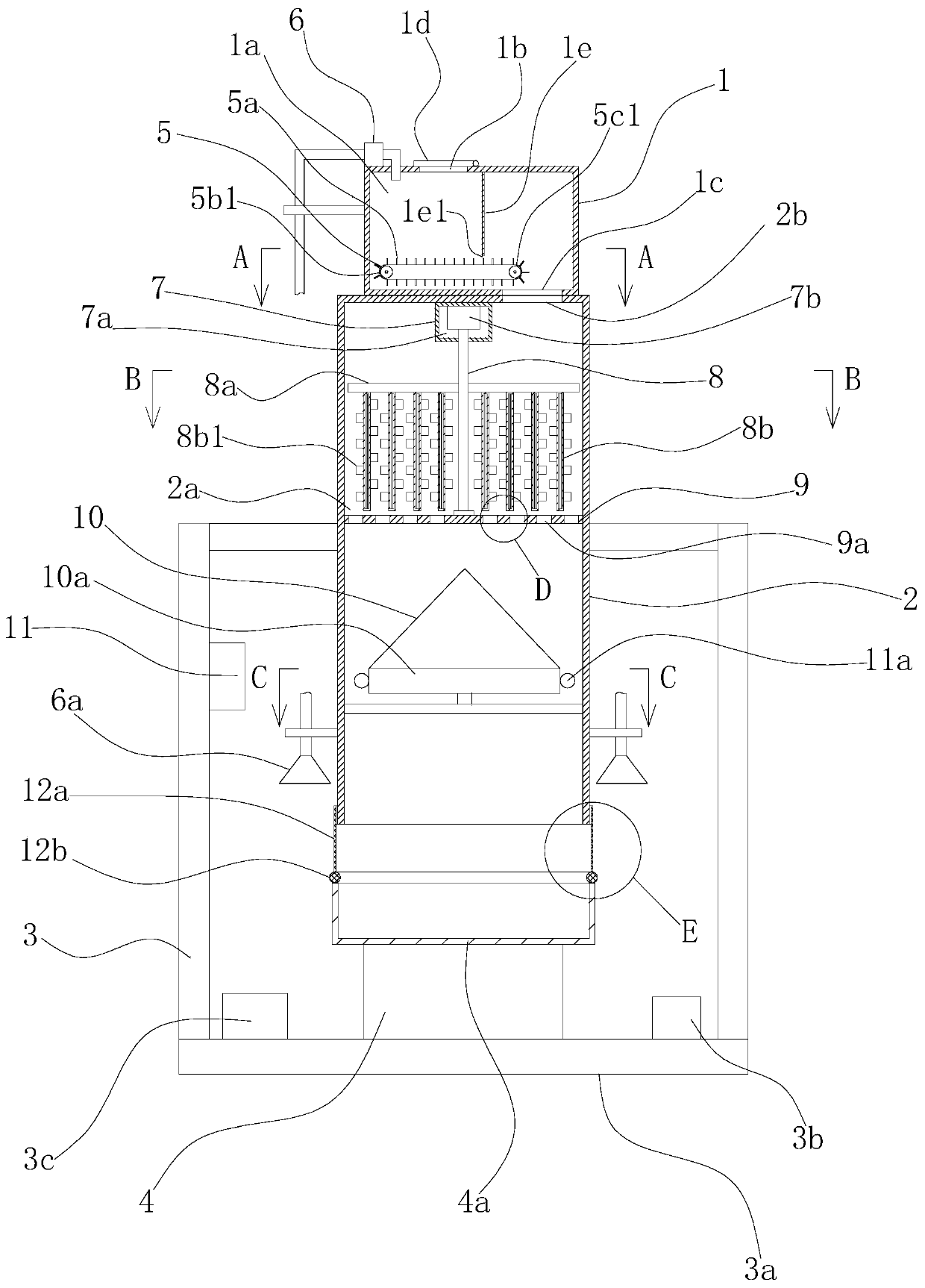

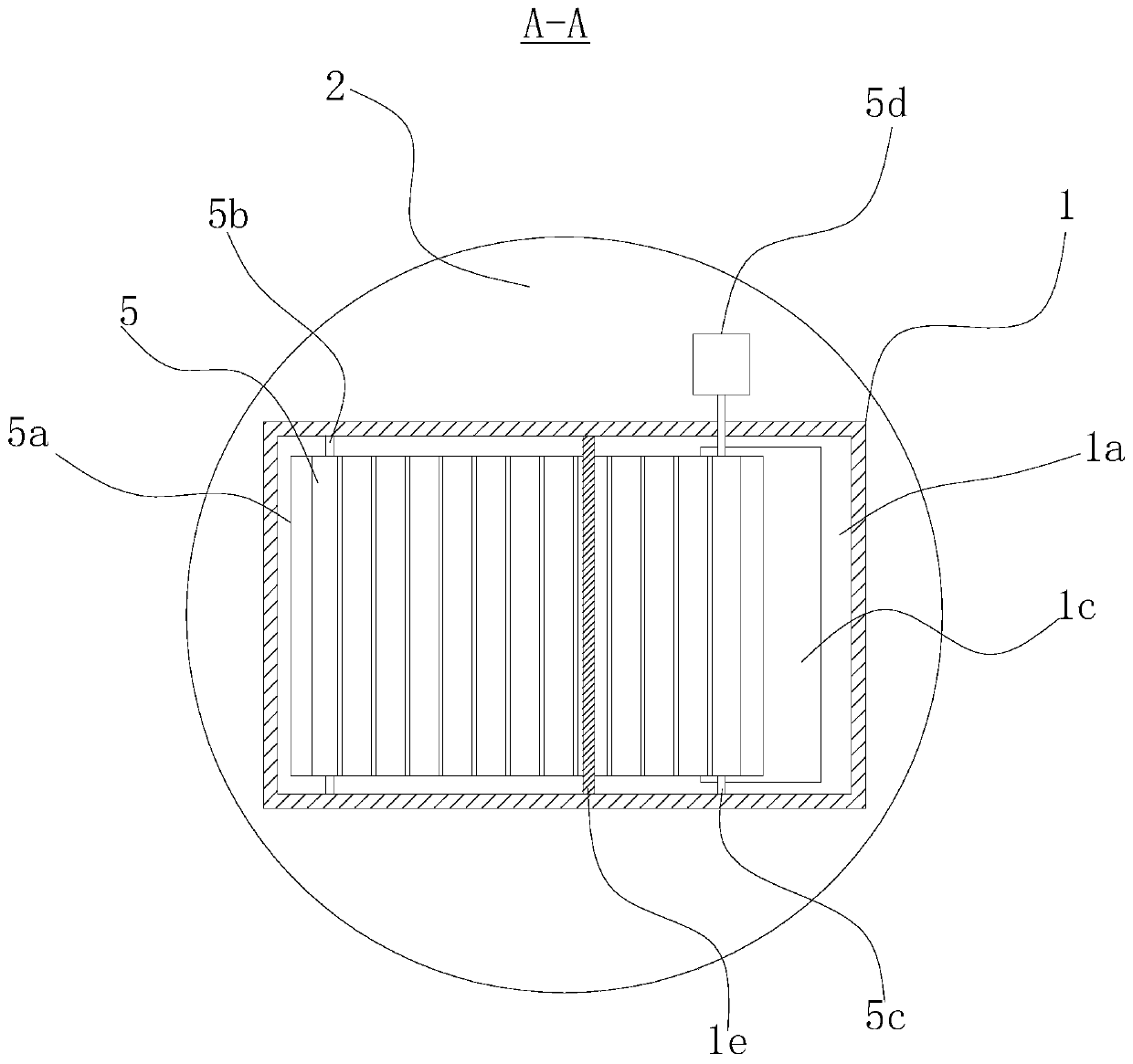

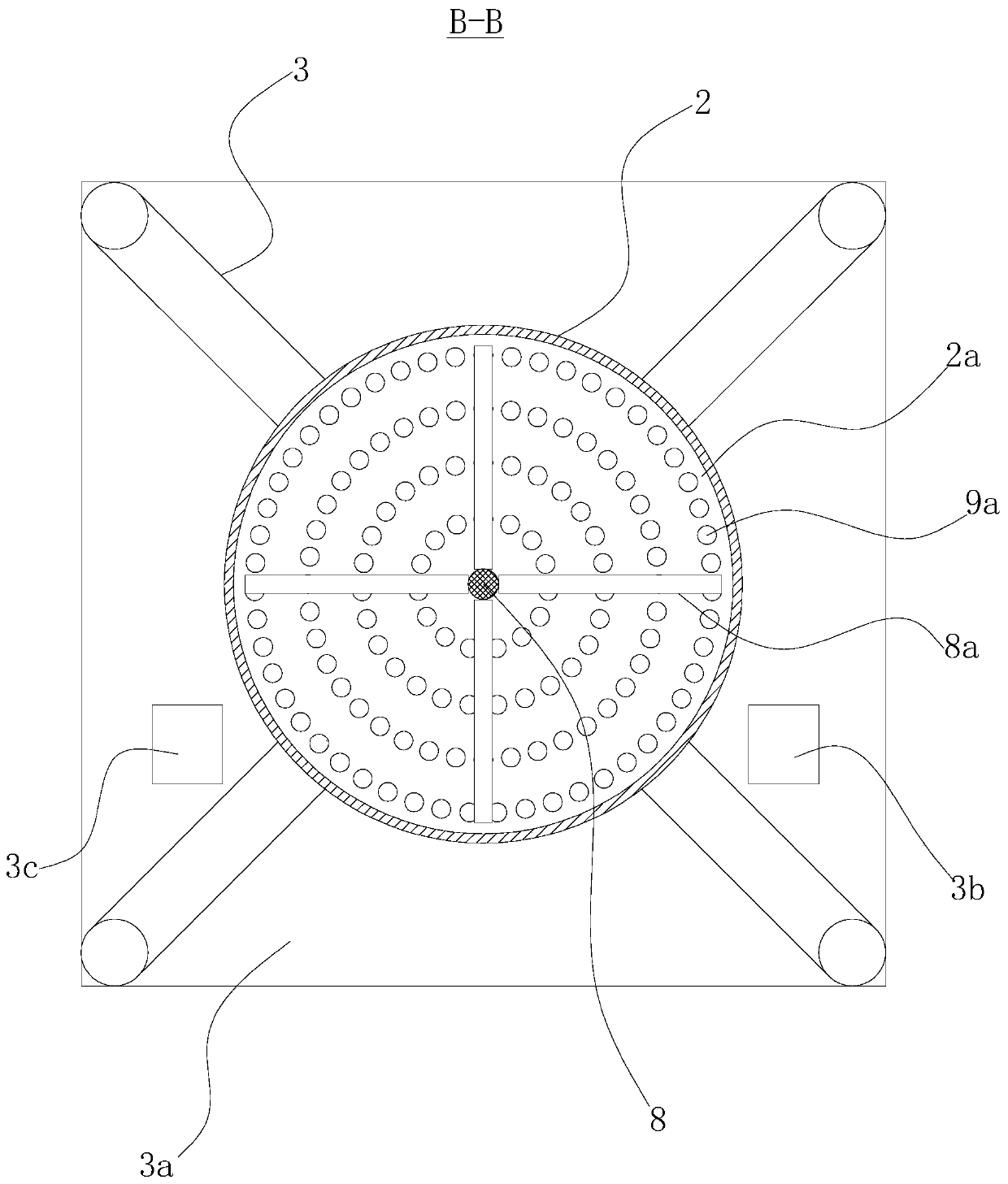

[0032] Such as Figure 1 to 6 As shown, a cement access device for a laboratory includes a storage box 1 and a discharge cylinder 2 with an opening at the lower end. The storage box 1 is arranged at the upper end of the discharge cylinder 2, and the discharge cylinder 2 passes through The four supporting legs 3 are arranged on the base plate 3a, the storage box 1 is provided with a storage cavity 1a, the upper side of the storage box 1 is provided with a feeding port 1b, and a cover plate 1d is hinged on the feeding port 1b, The lower side of the storage box 1 is provided with a through hole 1c, and the upper end of the discharge barrel 2 is provided with a through hole 2b. The through hole 1c and the through hole 2b are of the same size and overlap each other. The box 1 is provided with a conveying mechanism capable of uniformly conveying the cement in the storage cavity 1a to the through hole 1c. The discharging barrel 2 is horizontally provided with a partition 9 which is co...

Embodiment 2

[0046] The second embodiment is basically the same as the first embodiment, but the difference lies in: figure 1 with 3 As shown, the base plate 3a is also provided with a battery 3c. The motor one 5d, the dust suction pump 6, the motor two 7b, the electric heating wire 8d, the electric air pump 11 and the ring electromagnet 12b are all connected to the battery through the controller 3b. 3c Electrical connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com