Super-hydrophobic glass rainproof agent aerosol composition and preparation method thereof

A rainproof agent and aerosol technology, applied in coatings, epoxy resin coatings, etc., can solve problems such as unclear front and rear distances, safety hazards, traffic safety hazards, etc., achieve good hydrophobicity and light transmittance, and improve hydrophobicity. Angle, the effect of improving the rainproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

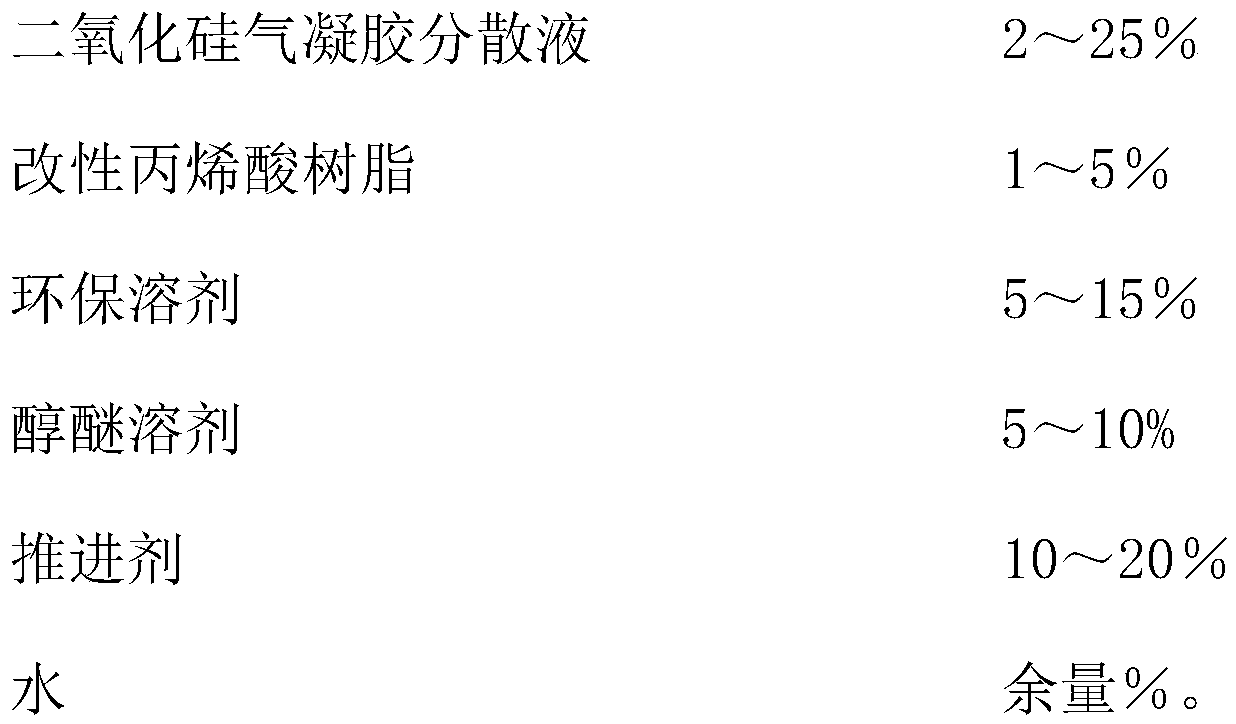

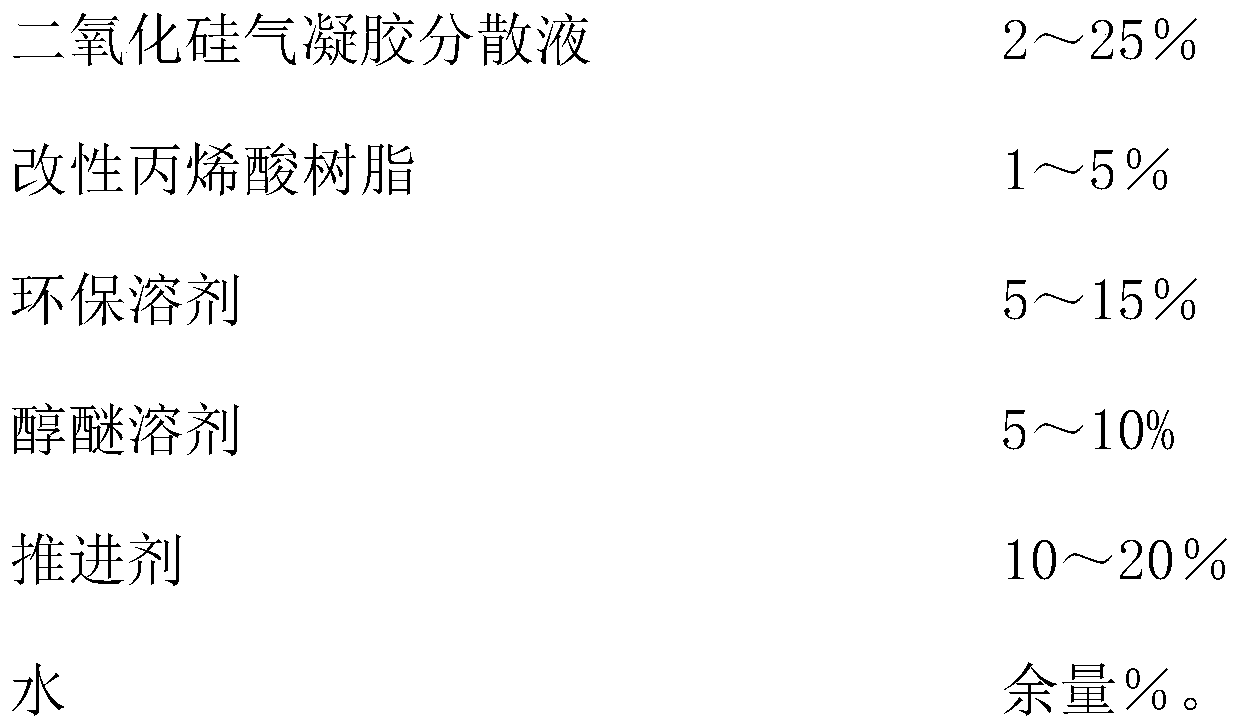

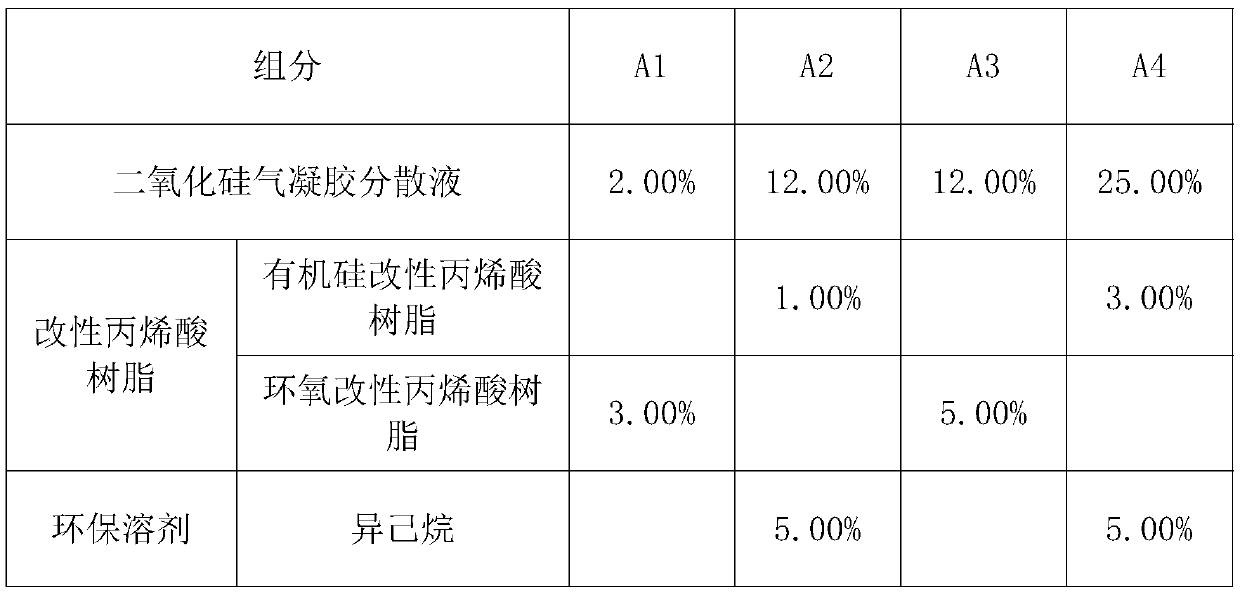

[0030] At room temperature, first put the silica airgel into a nano-sand mill, and grind it at 2000r / min for 60min to obtain an ultrafine silica airgel powder with a particle size of ≤5 microns, and mix it with absolute ethanol at 1 : Add the high-speed disperser at a weight ratio of 4, stir with 1000r / min rotating speed for 60min, obtain the silica airgel dispersion liquid, for subsequent use; press the weight percentage of Table 1, add the weighed heptane, isomerized dodecane In deionized water, stir at 300r / min for 10min, then add the weighed silica airgel dispersion and stir at 800r / min for 50min, then add the weighed epoxy-modified acrylic resin, propylene glycol, ethylene glycol , Stir at 800r / min for 20min, put the mixed liquid into the aerosol tank, plug in the valve, seal, fill in dimethyl ether, install the spray cap, and you have it.

[0031] The product produced in Example 1 is designated as A1.

Embodiment 2

[0033] At room temperature, first put the silica airgel into a nano-sand mill, and grind it at 2000r / min for 60min to obtain an ultrafine silica airgel powder with a particle size of ≤5 microns, and mix it with absolute ethanol at 1 The weight ratio of :4 is added to a high-speed disperser, stirred at a speed of 1500r / min for 30min, and the silica airgel dispersion is obtained for subsequent use; by weight percentage in Table 1, the weighed heptane, isomerized dodecane, Add isohexane into deionized water, stir at 400r / min for 8min, then add the weighed silica airgel dispersion and stir at 1000r / min for 60min, then add the weighed epoxy-modified acrylic resin, propylene glycol, Isopropanol, stirred at 500r / min for 30min, put the mixture into the aerosol tank, plug in the valve, seal it, fill it with 1,1,1,2-tetrafluoroethane, install the spray cap, and you have it.

[0034] The product produced in Example 2 is designated as A2.

Embodiment 3

[0036] At room temperature, first put the silica airgel into a nano-sand mill, and grind it at 2000r / min for 60min to obtain an ultrafine silica airgel powder with a particle size of ≤5 microns, and mix it with absolute ethanol at 1 : Add the high-speed disperser at a weight ratio of 4, stir for 50min with 1200r / min rotating speed, obtain the silica airgel dispersion liquid, for subsequent use; press the weight percentage of Table 1, add the weighed isohexane, isododecane Stir in deionized water at 500r / min for 8min, then add the weighed silica airgel dispersion and stir at 1200r / min for 30min, then add the weighed epoxy-modified acrylic resin, isopropanol, propylene glycol , ethylene glycol, stirred at 600r / min for 25min, put the mixed solution into the aerosol tank, plug in the valve, seal, fill with nitrogen, install the spray cap, and you have it.

[0037] The product produced in Example 3 is designated as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com