TPU film with high hydrophobic angle, and preparation method thereof

A film and vacuum dehydration technology, applied in the field of TPU film and its preparation, high hydrophobic angle TPU film and its preparation, can solve the problems of small hydrophobic angle and poor hydrophobic performance, and achieve easy rolling off, good hydrophobic performance, and hydrophobic performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

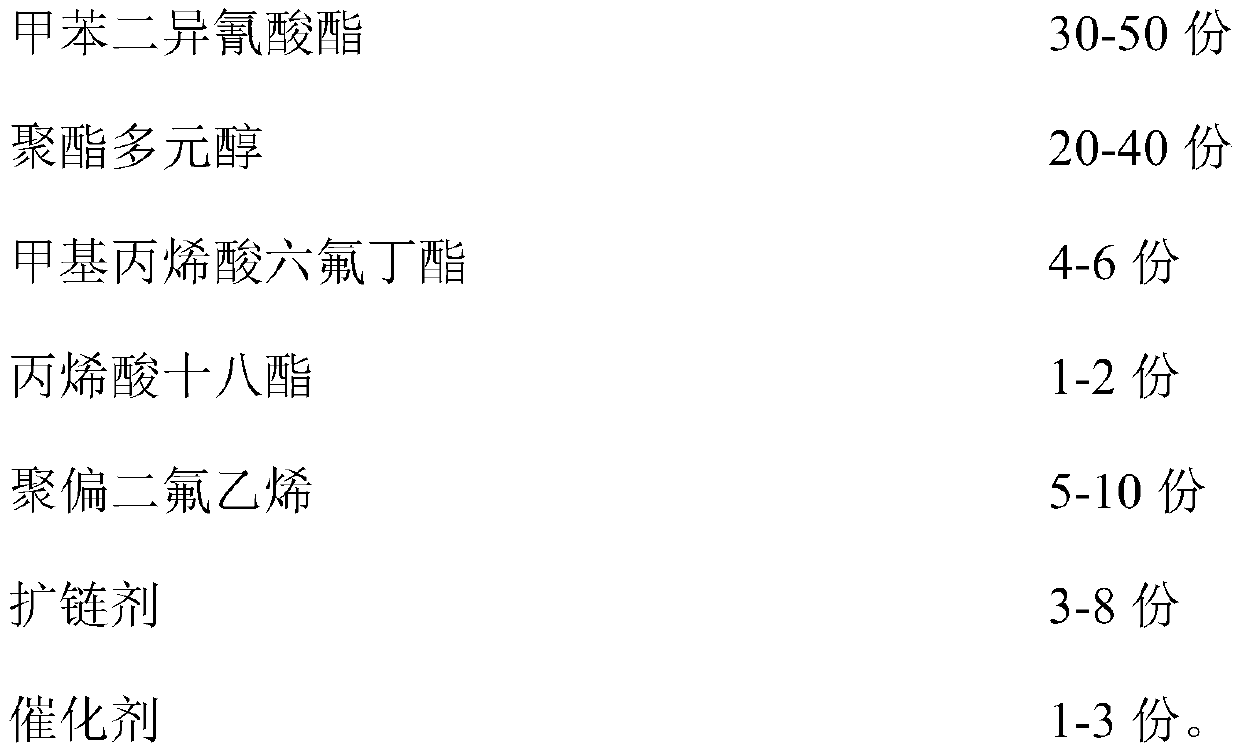

[0046] The preparation raw material of the TPU film that the present embodiment provides comprises the following components by weight:

[0047]

[0048] Preparation:

[0049] (1) Add toluene diisocyanate and polyethylene glycol adipate diol into the container, and under the condition of stirring at a speed of 160r / min, vacuum dehydrate at 65°C for 2 hours;

[0050] (2) Add 1,2-propanediol and dibutyltin dioctoate to step (1) and mix and react at 65°C for 18 hours;

[0051] (3) Add hexafluorobutyl methacrylate, octadecyl acrylate and polyvinylidene fluoride to the mixture after the reaction in step (2), stir and mix at 68°C for 18 hours, and then add to the twin-screw extruder The TPU film was obtained by extrusion molding, wherein the temperature of the feeding section of the twin-screw extruder was 115°C, the temperature of the mixing section was 150°C, the temperature of the extrusion section was 170°C, and the temperature of the head was 155°C.

Embodiment 2

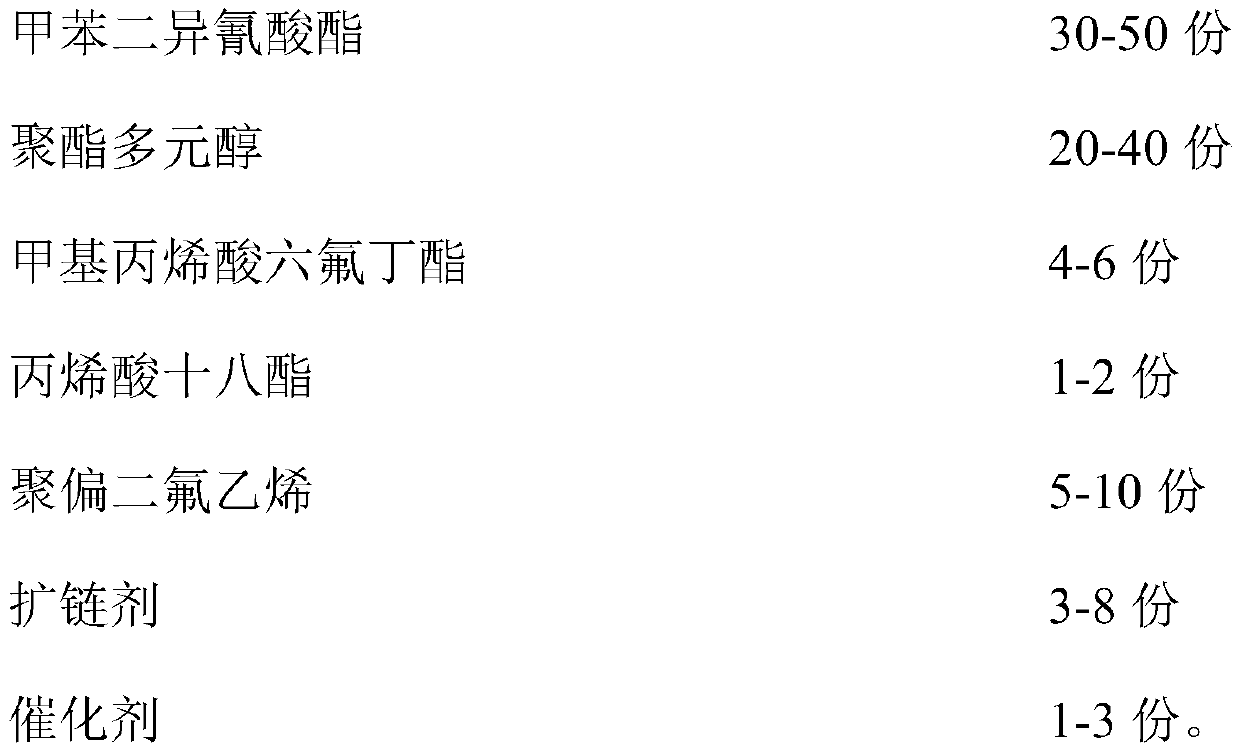

[0053] The preparation raw material of the TPU film that the present embodiment provides comprises the following components by weight:

[0054]

[0055] Preparation:

[0056] (1) Add toluene diisocyanate and polyethylene adipate diethylene glycol diol into the container, and under the condition of stirring at a speed of 160r / min, vacuum dehydrate at 65°C for 2 hours;

[0057] (2) Add 1,2-propanediol and stannous octoate to step (1) and mix and react at 65°C for 18 hours;

[0058] (3) Add hexafluorobutyl methacrylate, octadecyl acrylate and polyvinylidene fluoride to the mixture after the reaction in step (2), stir and mix at 68°C for 18 hours, and then add to the twin-screw extruder The TPU film was obtained by extrusion molding, wherein the temperature of the feeding section of the twin-screw extruder was 115°C, the temperature of the mixing section was 150°C, the temperature of the extrusion section was 170°C, and the temperature of the head was 155°C.

Embodiment 3

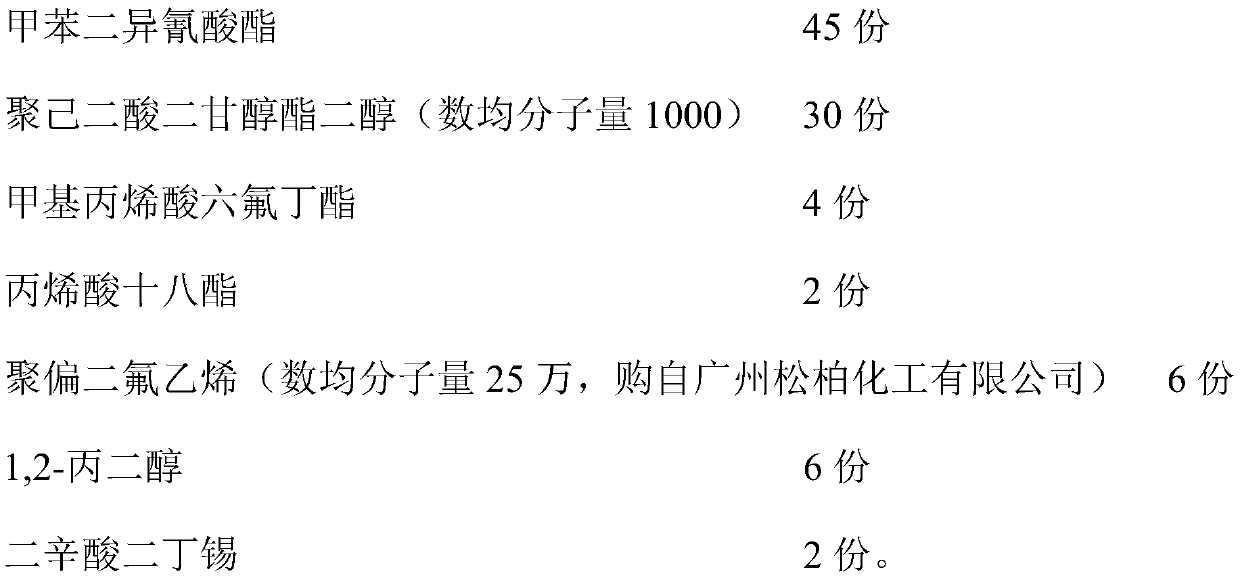

[0060] The preparation raw material of the TPU film that the present embodiment provides comprises the following components by weight:

[0061]

[0062] Preparation:

[0063] (1) Add toluene diisocyanate and polyethylene adipate propylene glycol ester diol into the container, and under the condition of stirring at a speed of 160r / min, vacuum dehydrate at 65°C for 2 hours;

[0064] (2) Add ethylene glycol and dibutyltin diacetate to step (1) and mix and react at 65°C for 18 hours;

[0065] (3) Add hexafluorobutyl methacrylate, octadecyl acrylate and polyvinylidene fluoride to the mixture after the reaction in step (2), stir and mix at 68°C for 18 hours, and then add to the twin-screw extruder The TPU film was obtained by extrusion molding, wherein the temperature of the feeding section of the twin-screw extruder was 115°C, the temperature of the mixing section was 150°C, the temperature of the extrusion section was 170°C, and the temperature of the head was 155°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com