Method and device for monitoring energy of non-chain pulse chemical laser in real time

A real-time monitoring and laser technology, applied in the field of non-chain pulse chemical laser, can solve the problems of large energy, influence of laser transmission, and inability to respond to changes in laser pulse energy in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

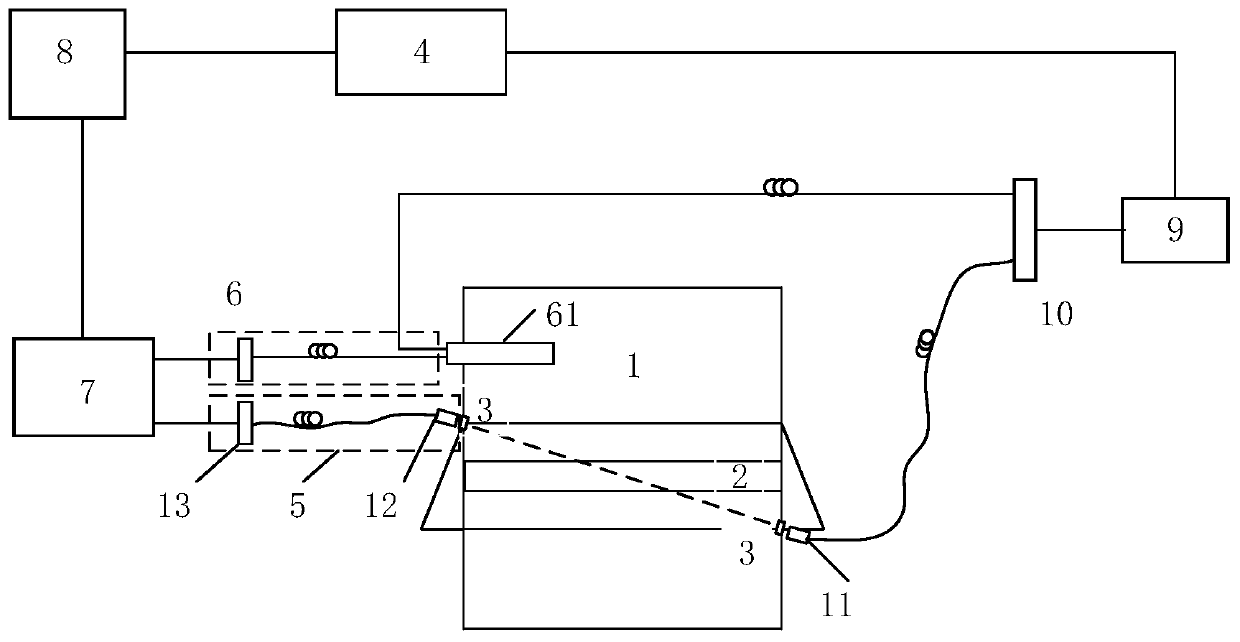

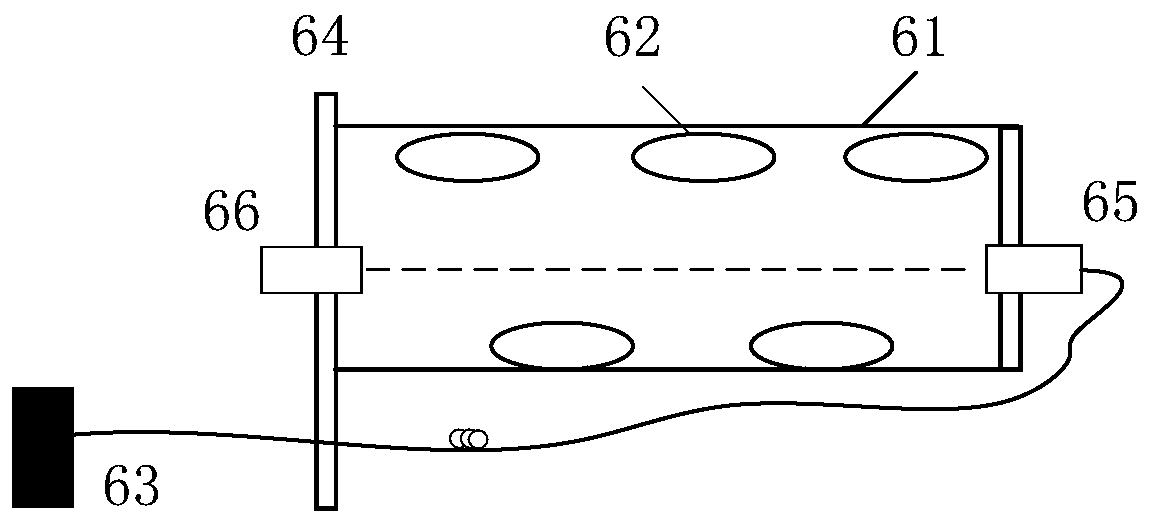

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0056] The invention is applicable to non-chained HF lasers, DF lasers, and other pulsed chemical lasers. The following embodiments are described by taking an HF laser as an example.

[0057] In this embodiment, the method for real-time monitoring of the non-chain pulsed HF laser energy is realized through the following steps:

[0058] Step 1. Adjust the parameters of the tunable narrow-linewidth laser according to the characteristic spectral lines of the gas molecules in the measured laser, so as to ensure that the scanning wavelength range of the tunable narrow-linewidth laser only covers one characteristic spectral line of the HF gas molecules;

[0059] Step 2. Splitting the tunable narrow-linewidth laser in step 1 and simultaneously irradiating the gain region and the non-gain region of the laser under test respectively;

[0060] Step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com