Neural network prediction method based on principal component analysis

A principal component analysis and neural network technology, applied in the field of automation industry, can solve the problems of low modeling accuracy, data redundancy, and high modeling complexity, and achieve the effects of reducing data dimensions, improving accuracy, and avoiding redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below.

[0045] Take the ethylene oxidation reactor as an example:

[0046] The ethylene reactor is a fixed-bed tubular reactor. The raw materials ethylene and oxygen pass through the reactor continuously, and directly react on the surface of the catalyst to generate ethylene oxide. The yield is a key control index, and the yield prediction of the ethylene oxidation reactor is established. The model takes six measurable variables as the input variables of the reactor yield prediction model, and takes the reactor yield as the output of the model.

[0047] Step 1. Collect the variables affecting the yield of the ethylene oxidation reactor and the yield of the reactor, and process the data by principal component analysis. The specific steps are:

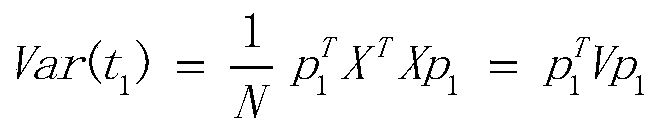

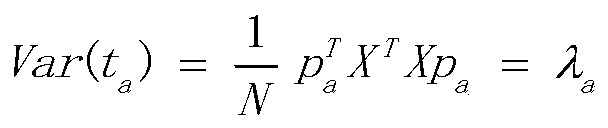

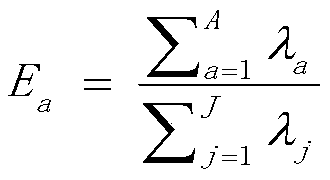

[0048] 1-1. Define the first principal component of the variable affecting the yield of the ethylene oxidation reactor in the following form:

[0049] t 1 =Xp 1 =[v 1 v 2 .....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com