Dual-side cooling heat sink

A double-sided cooling and radiator technology, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problem of affecting the normal operation of high-power components, potential safety hazards of new energy vehicles, and damage to high-power components and other problems, to achieve the effect of overcoming high welding defect rate, simple structure, and protecting heating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

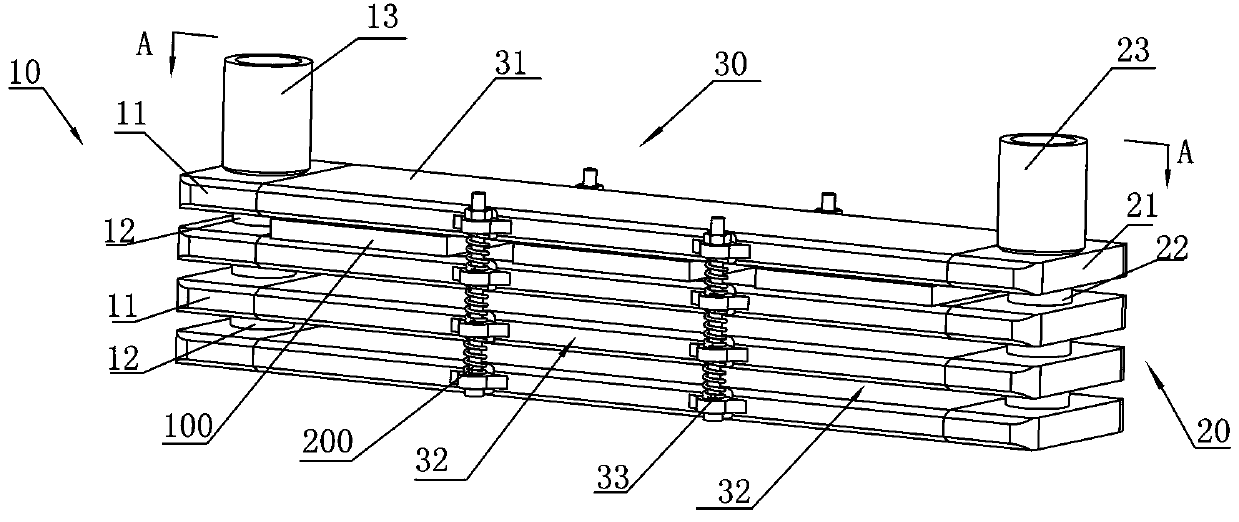

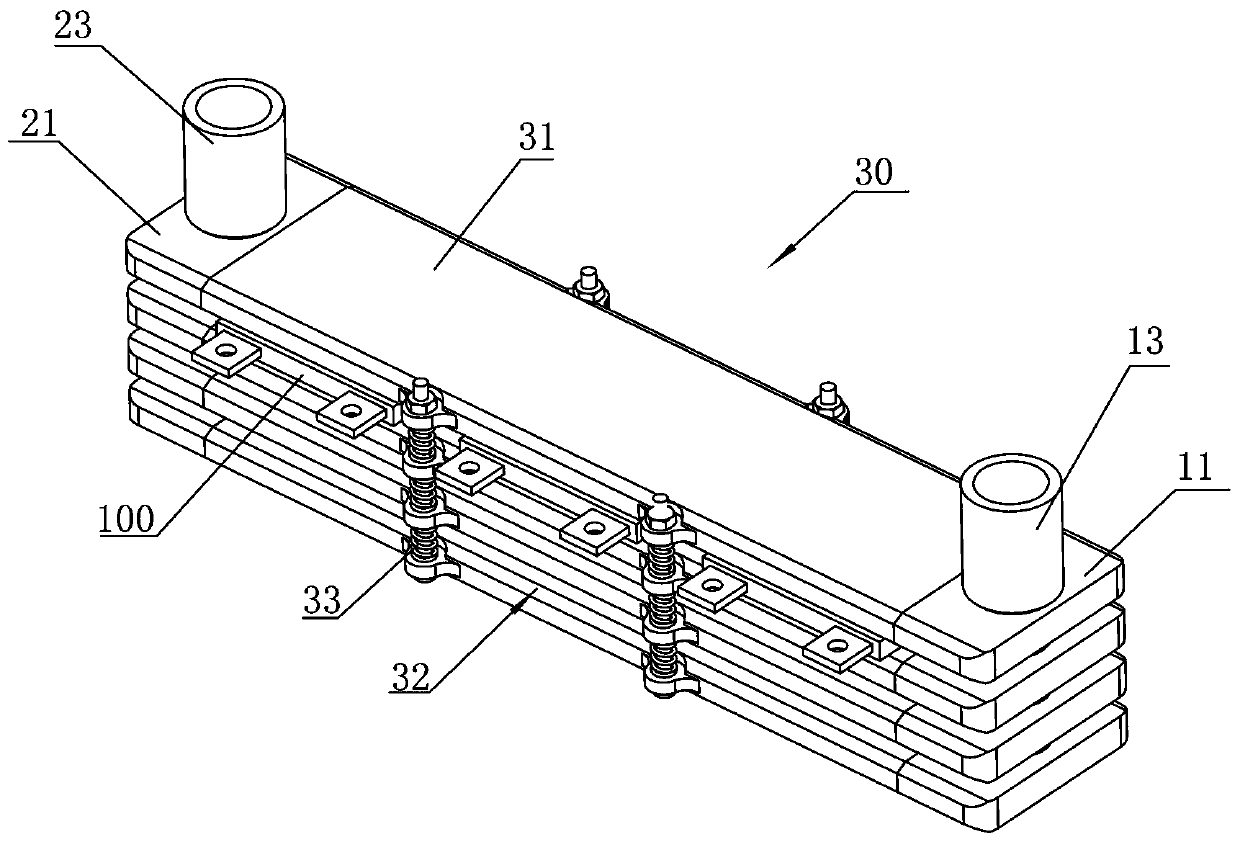

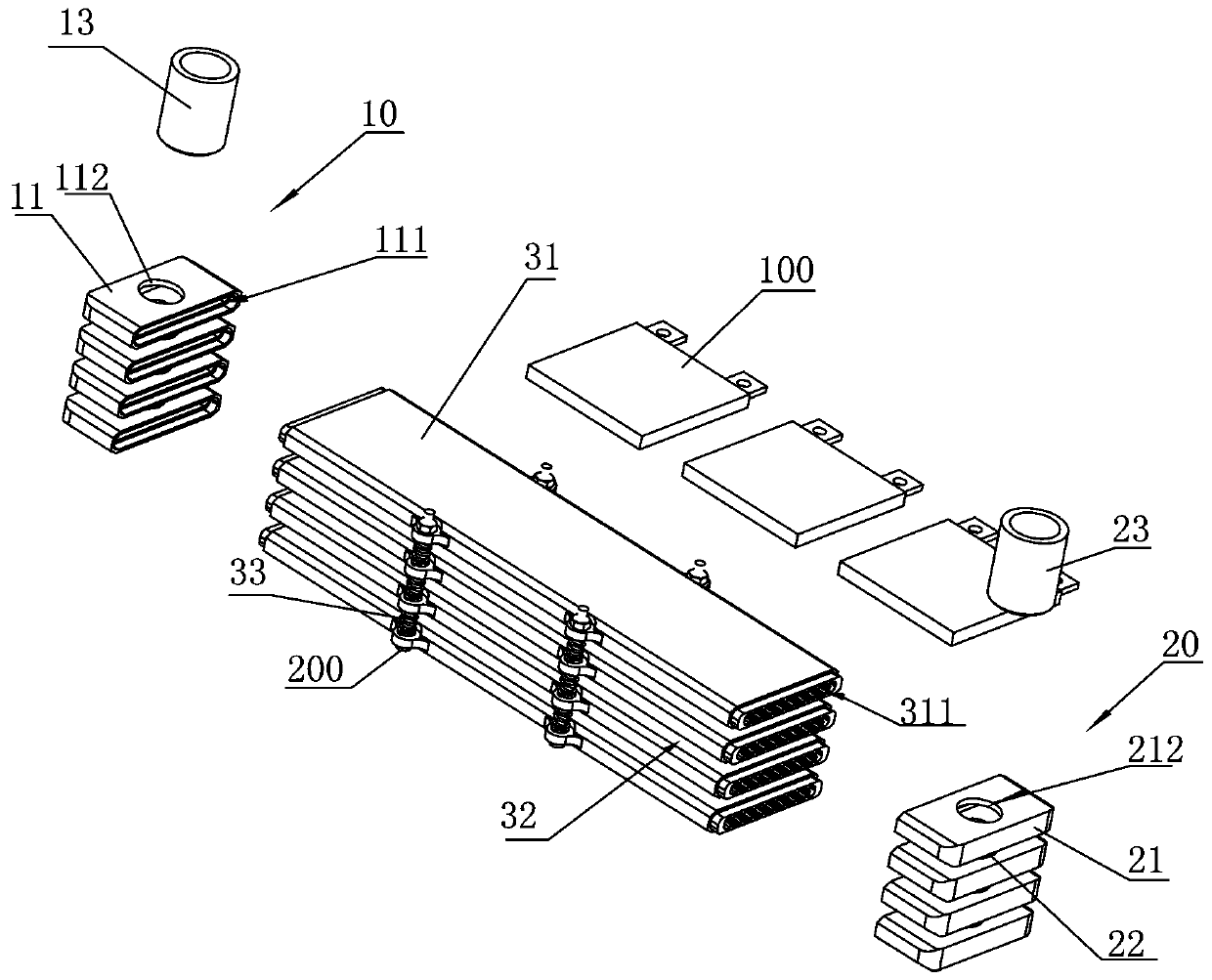

[0019] Figure 1 to Figure 6 , is a preferred embodiment of a double-sided cooling radiator provided by the present invention. Such as Figure 1 to Figure 6 As shown, the double-sided cooling radiator includes a set of water inlet blocks 10, a set of water outlet blocks 20, and a cooling plate body group 30 that is sealed and docked with the water inlet block group and the water outlet block group. The block group 10 includes at least two stacked water inlet blocks 11, two adjacent water inlet blocks 11 are connected as a whole through a water inlet pipe 12, each water inlet block 11 has a water inlet cavity 111, and is in the A water inlet 112 is provided on the top water inlet block; the water outlet block group 20 includes at least two stacked water outlet blocks 21, and two adjacent water outlet blocks 21 are connected as a whole thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com